Crushing and classifying equipment for limestone processing

A kind of classification equipment, limestone technology, applied in the field of crushing and classification equipment for limestone processing, can solve the problems of inability to classify limestone size particles, affect air environment sanitation, delay work efficiency, etc., achieve convenient screening, protection from pollution, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

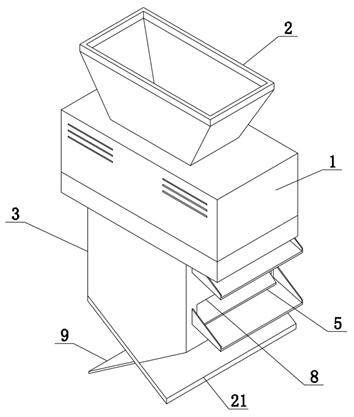

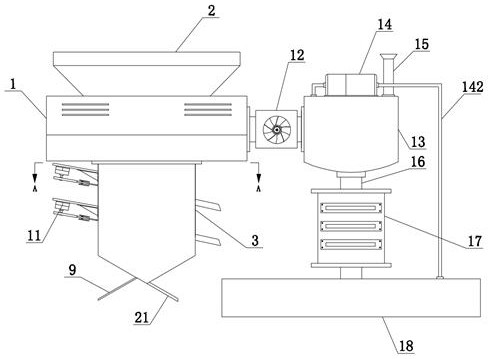

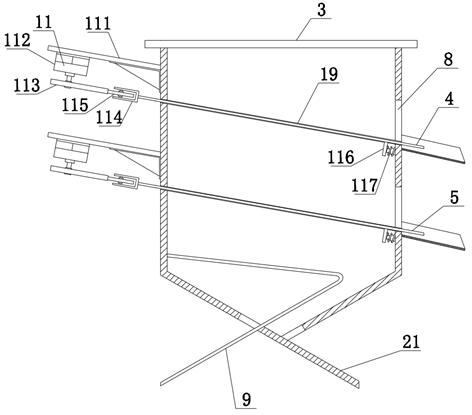

[0037] see Figure 1 to Figure 9 , a crushing and sorting equipment for limestone processing, comprising a crushing device body 1, the upper end of the crushing device body 1 is fixedly equipped with a feed port 2, and the lower end of the crushing device body 1 is fixedly installed with a classification box 3, and the classification The inner side of the case 3 is movably connected with a first sieve plate 4, and the inside of the classification box 3 is movably connected with a second sieve plate 5 directly below the first sieve plate 4, and the inside of the first sieve plate 4 The upper end is provided with a first sieve hole 6, the upper end of the second sieve plate 5 is provided with a second sieve hole 7, and the right side of the classification box 3 corresponds to the first sieve plate 4 and the second sieve plate 5 are respectively provided with two outlets 8, and one end of the first sieve plate 4 and the second sieve plate 5 extends out of the outlet 8, and the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com