Aircraft fuel tank with energy absorption protection function and leading edge slat

A leading-edge slat and aircraft fuel tank technology, which is applied to power plant fuel tanks, layered products, chemical instruments and methods, etc., can solve problems such as occupying a large space, reducing the fuel storage capacity of the fuel tank, and weak buffering and energy-absorbing capabilities , to achieve the effect of preventing fuel leakage incidents, reducing the possibility and improving the anti-collision ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

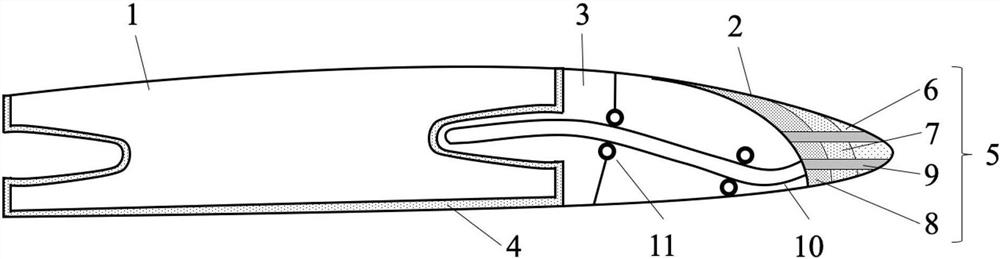

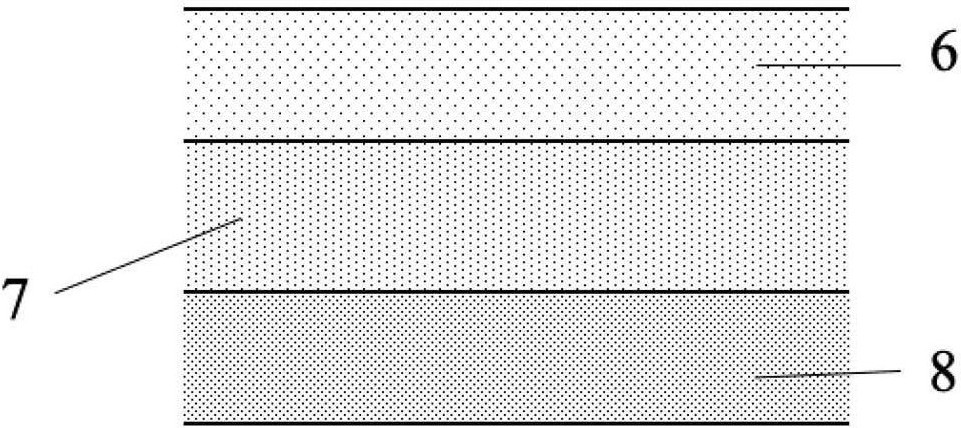

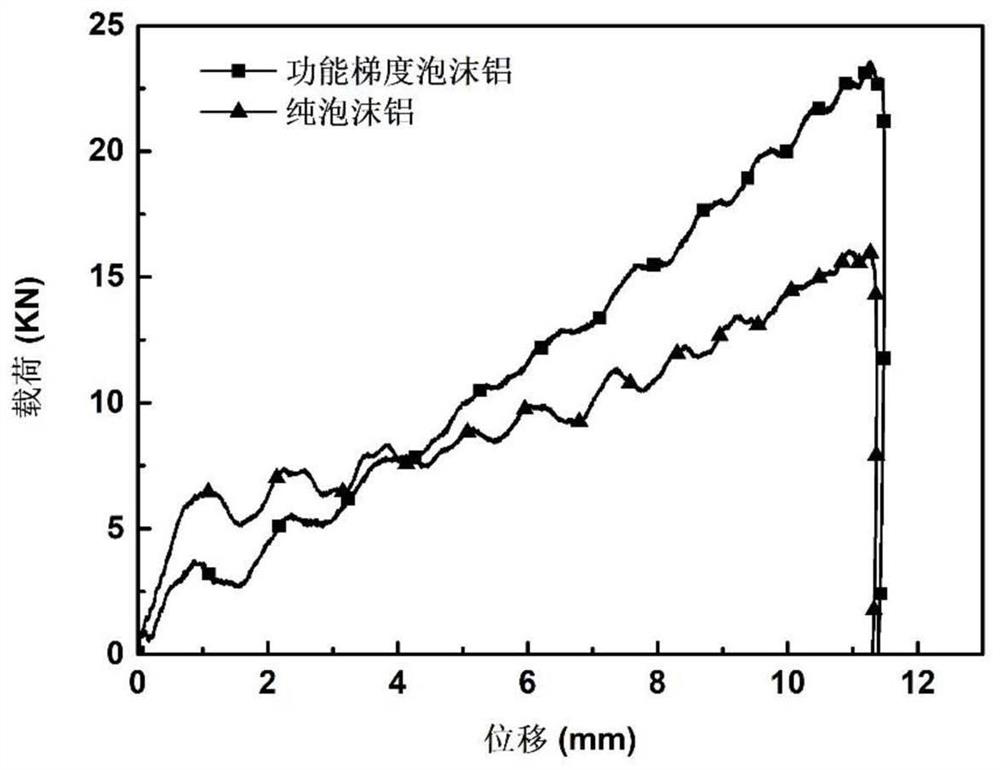

[0033] An aircraft fuel tank and leading-edge slats with energy-absorbing protection functions, such as figure 1 As shown, it includes a fuel tank 1 , a slat 2 and a rail chamber 3 , the fuel tank 1 and the slat 2 are connected through a guide rail 10 in the rail chamber 3 , and the guide rail 10 is assisted by a roller 11 . A buffer energy-absorbing layer 4 is arranged on the inner wall of the oil tank 1, and the buffer energy-absorbing layer 4 is a composite foam with a composition gradient. The composite foam with a composition gradient is made by powder metallurgy filling with a pore-forming agent. figure 2As shown, the buffer energy-absorbing layer 4 in this embodiment is composed of a pure aluminum foam layer 6, a middle carbon nanotube-reinforced aluminum-based composite foam layer 7, and an inner carbon nanotube-reinforced aluminum-based composite foam layer 8, which are sequentially arranged from outside to inside. The anti-bird strike structure in the leading edge s...

Embodiment 2

[0039] In this embodiment, the anti-bird strike structure includes a composite material layer and a gradient aluminum foam filling tube. The composite material layer is made by powder metallurgy filling and adding a pore-forming agent. Carbon nanotube reinforced aluminum matrix composite foam, the density of pure foamed aluminum is 0.54g / cm 3 , the corresponding porosity is 80%; the mass fraction of carbon nanotubes in the middle carbon nanotube reinforced aluminum matrix composite foam is 2wt.%, and the porosity is 70%; the mass fraction of carbon nanotubes in the inner carbon nanotube reinforced aluminum matrix composite foam is 2wt.%, the porosity is 60%. The gradient aluminum foam filling tube is made of 5 layers of density gradient aluminum foam with a porosity of 50-80% in situ filling an aluminum alloy thin-walled tube with a wall thickness of 2mm. The density gradually increases from the outside to the direction close to the fuel tank. The diameter of the foam aluminum...

Embodiment 3

[0042] In this embodiment, the anti-bird strike structure includes a composite material layer and a gradient aluminum foam filling tube. The composite material layer is made by powder metallurgy filling and pore-forming agent method. It consists of two layers of pure foam aluminum blocks on the outside and two layers of carbon nanotube reinforced aluminum in the middle. Al-based composite foam and two layers of carbon nanotube-reinforced aluminum-based composite foam on the inner side; along the direction close to the fuel tank, the density of the two outer layers of aluminum foam is 0.54g / cm 3 , 0.81g / cm 3 , the corresponding porosity is 80% and 70%, the mass fraction of carbon nanotubes in the middle two layers of carbon nanotube reinforced aluminum matrix composite foam is 2wt.%, the porosity is 70%, 60% respectively, the inner two layers of carbon nanotubes The mass fraction of carbon nanotubes in reinforced aluminum matrix composite foam is 2 wt.%, and the porosity is 60%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com