Foundation pit support system with firstly-supporting and secondly-digging construction method piles combined with inclined piles

A technology for foundation pit enclosure and construction method piles, which is applied in excavation, sheet pile wall, foundation structure engineering and other directions, can solve the problems of narrow foundation pit construction operation surface, difficulty in excavating earth in the pit, affecting the total construction period, etc. The effect of convenience, low cost and few technical difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

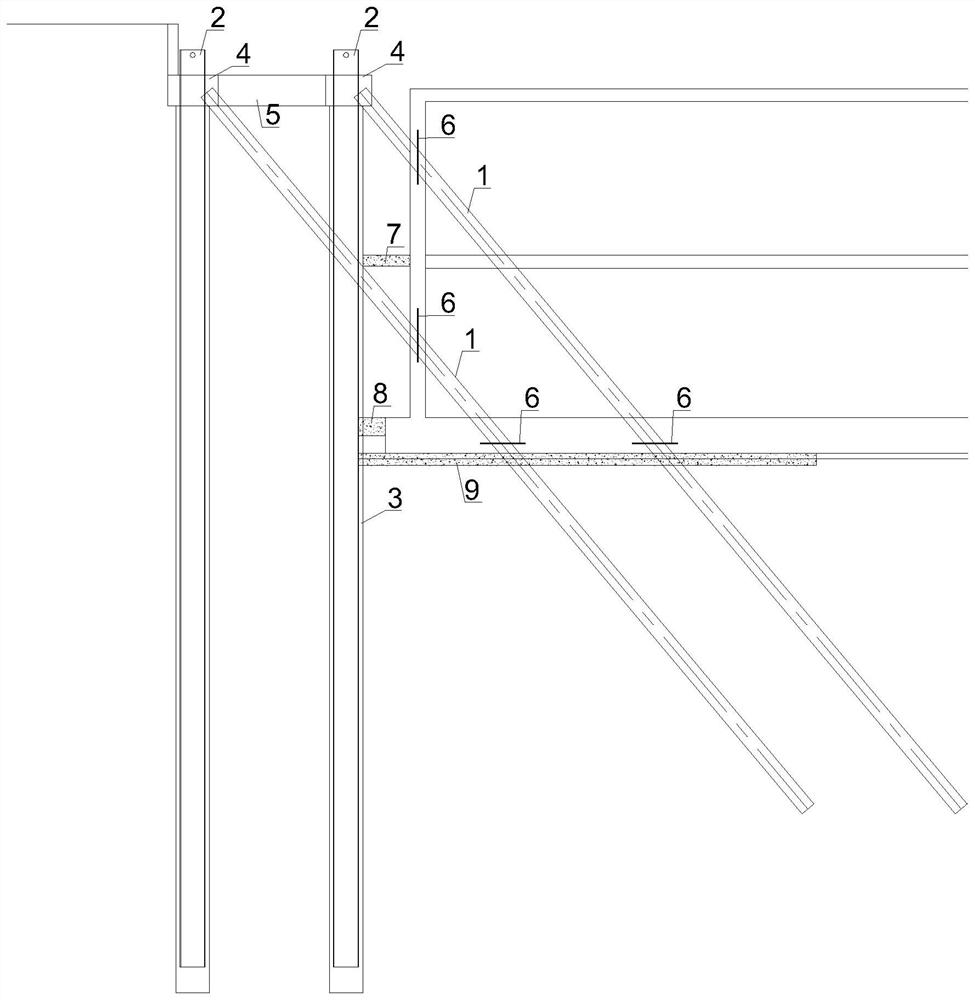

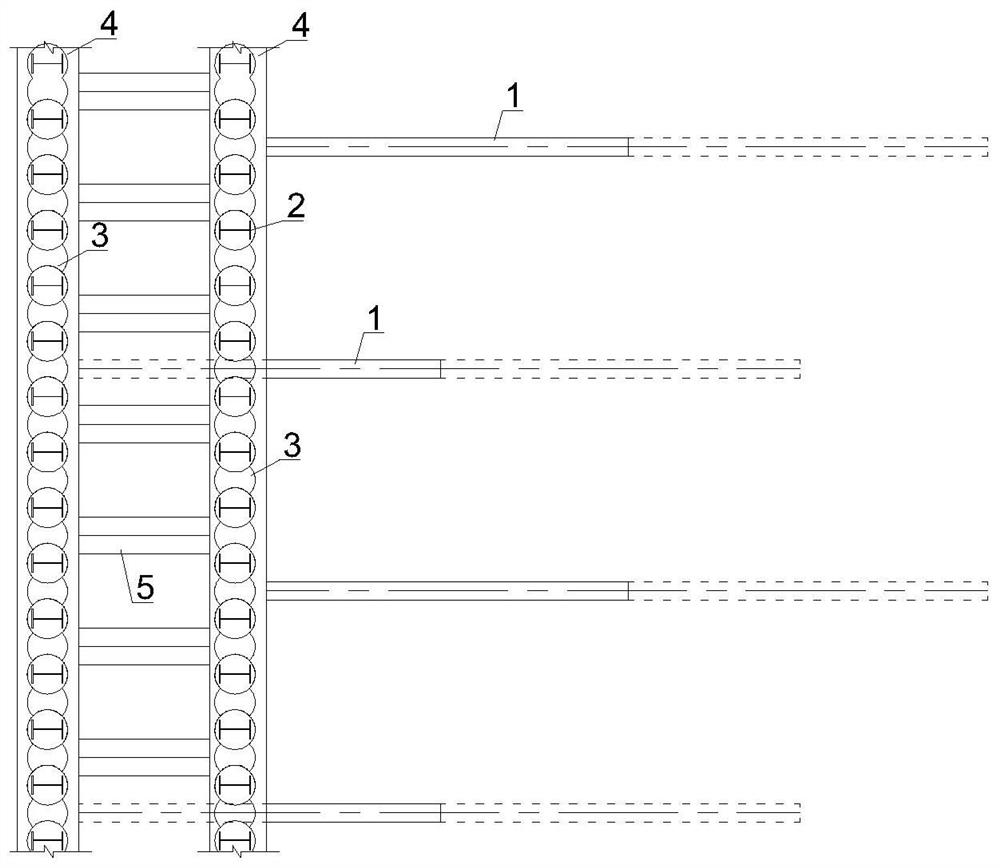

[0015] The present invention is described in detail with reference to the drawings and specific embodiments. Embodiments are carried out on the premise of the technical solution of the present invention, and the detailed implementation and specific operation process are given below. The protection object of the present invention is the structural form of the present invention itself, but the protection scope of the present invention is not limited to the following embodiments.

[0016] Embodiment of the present invention and concrete operation process are:

[0017] 1) Level up the construction site and release actual samples according to the construction drawings;

[0018] 2) Construct two rows of vertical cement-soil mixing piles and insert H-shaped steel;

[0019] 3) Use special machinery or high-pressure rotary grouting pile guide holes to construct two inclined piles;

[0020] 4) Excavate the earthwork to the crown beam construction operation surface, the top of the obl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com