Rapid grouting and hole sealing device for tunnel lining structure and using method

A sealing device and grouting technology, which is applied in the direction of tunnel lining, tunnel, shaft lining, etc., can solve the problems of changing, grouting conduit can not recycle the grouting depth, etc., to avoid leakage, ensure the effect of recycling, and avoid spring the winding effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

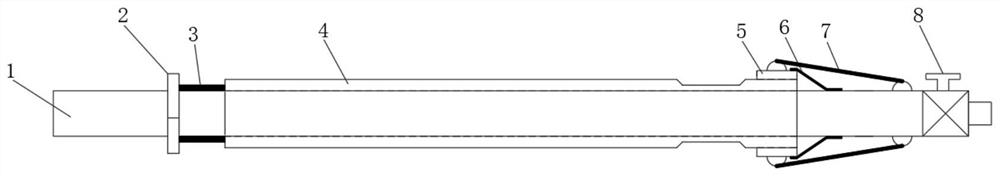

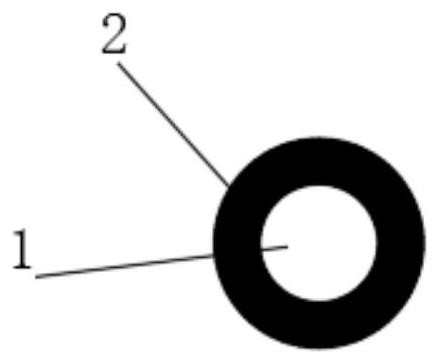

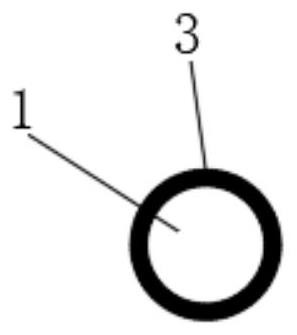

[0037] In a typical embodiment of the present invention, such as Figure 1-Figure 4 As shown, a rapid grouting and sealing device for tunnel lining structure is proposed, which includes a grouting conduit 1, a jacket steel pipe 4, a sealing mechanism and a rotation limit mechanism. At the entrance, one end of the grouting conduit 1 close to the grouting port is sequentially sleeved with a sealing mechanism and a jacket steel pipe 4, and the other end of the grouting conduit 1 is provided with a rotation limiting mechanism.

[0038] Specifically, the length of the jacket steel pipe 4 is shorter than the grouting conduit 1, and the jacket steel pipe 4 is sleeved on the grouting conduit 1 to form a casing structure with the grouting conduit 1. The outer wall of the grouting conduit 1 is provided with threads, and the inner wall of the jacket steel pipe 4 Threads are also provided on the top, and the rotation connection between the grouting conduit 1 and the jacket steel pipe 4 is...

Embodiment 2

[0055] In another typical embodiment of the present application, a method for using a rapid grouting sealing device for tunnel lining structures as described in Embodiment 1 is provided, and the specific process is as follows:

[0056] First put the fast grouting sealing device into the borehole so that the distance between the grouting port and the bottom of the borehole meets the grouting depth requirement;

[0057] Secondly screw into the jacket steel pipe 4, squeeze the expansion rubber tube 3 under the cooperation of the stopper 2, so that the expansion rubber tube 3 expands, and utilize the expansion rubber tube 3 to isolate the borehole from the outer space;

[0058] Then the grouting inlet end of the grouting conduit 1 is connected with the grouting equipment, the valve 8 is clocked in for grouting, and after the grouting is completed, the valve 8 is closed to stop the grouting;

[0059] Finally, after the grout is solidified, turn back the jacket steel pipe 4 to reset...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com