Mixing assembly for aftertreatment unit of vehicle exhaust system

A technology for mixing components and exhaust systems, which is applied in exhaust treatment, mixers, exhaust devices, etc., can solve the problems of increasing the weight of mixing components, easily accumulating deposits, and requiring multiple punching and stamping processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments illustrating the features of the present invention will now be described in detail. The words "comprises," "has," "comprises," and "comprises," as well as their other forms, are synonymous and open-ended since one or more items following any of these words do not imply This is an exhaustive list of one or more such items, or is intended to be limited to one or more of the items listed.

[0022] The terms "first", "second", etc. do not indicate any order, quantity or importance herein, but are used to distinguish one element from another element, and the term "a" here does not express a limitation on quantity, but Yes indicates that at least one of the referenced items exists.

[0023] The disclosed embodiments are merely examples of the invention, which may be embodied in various forms.

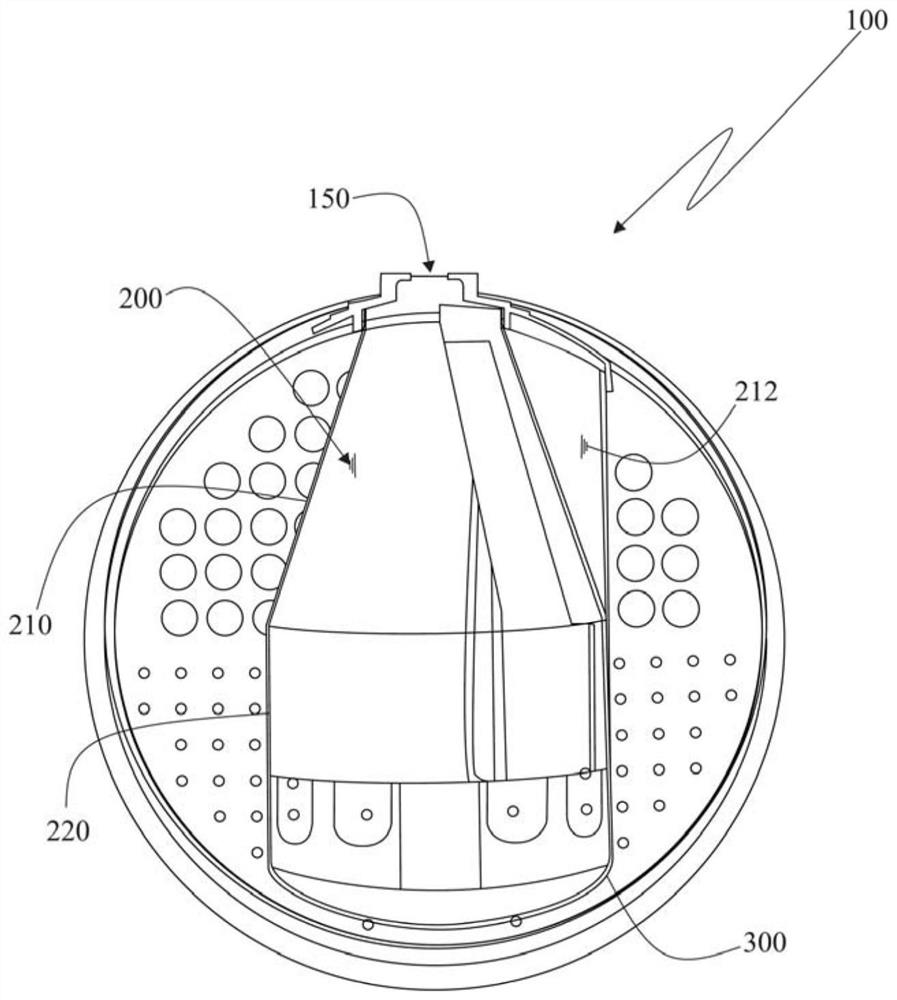

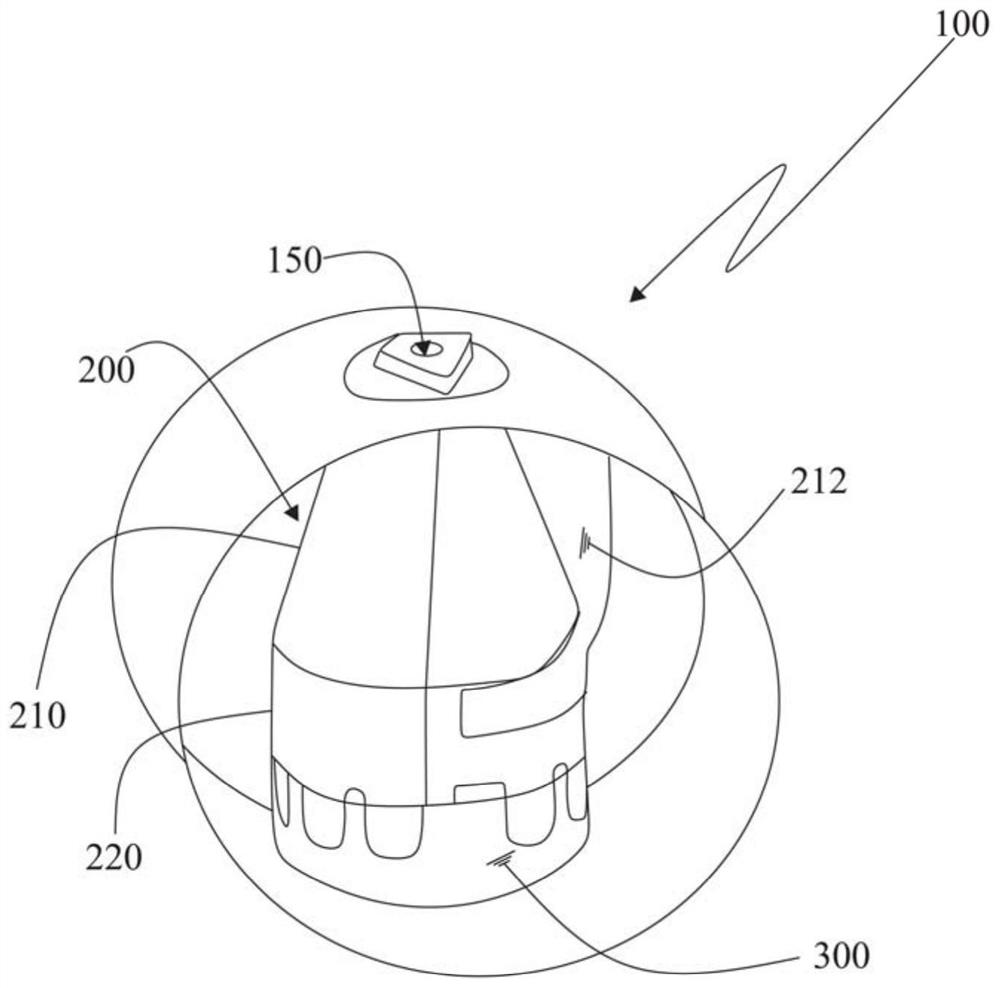

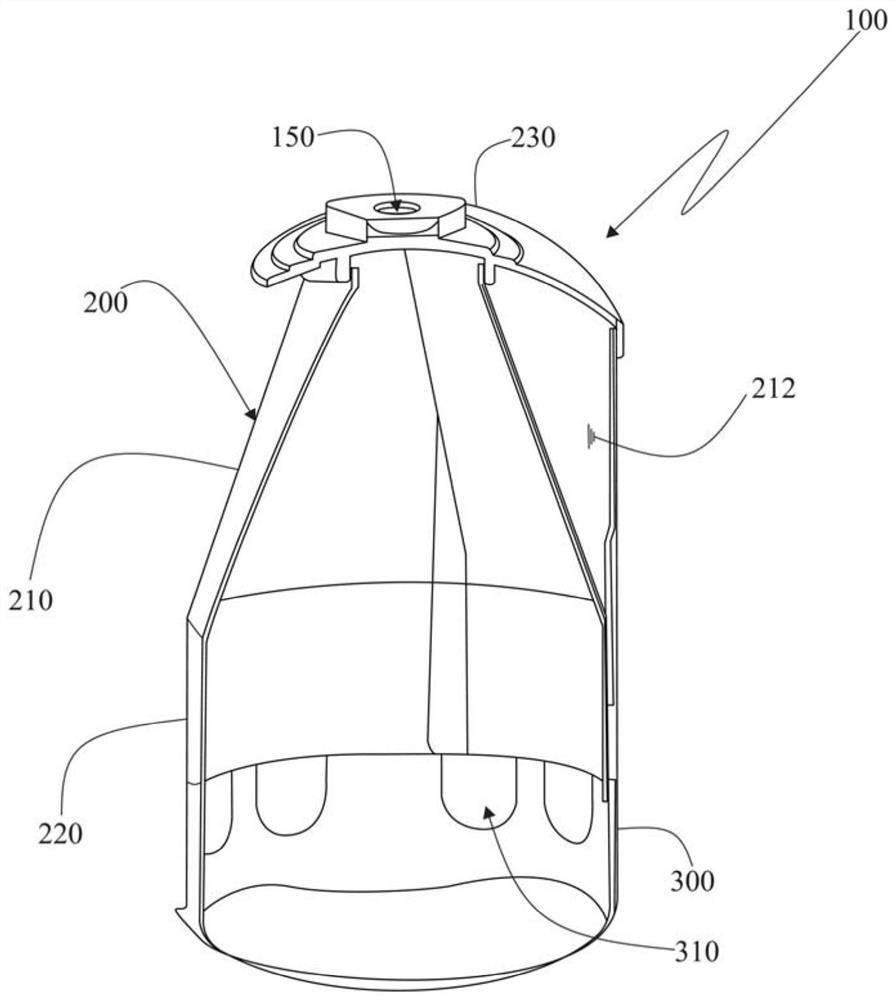

[0024] The invention relates to a mixing assembly for an aftertreatment unit arranged inside the exhaust system of a vehicle. Preferably, the aftertreatment unit of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com