Aerated brick waste heat and waste pressure recycling system

A technology of recycling and aerated bricks, which is used in water heaters, lighting and heating equipment, preheating, etc., can solve the problems of low structural strength of the holes and walls of aerated bricks, inability to be used as wall materials, and the use of a lot of manpower and material resources. , to achieve the effect of realizing resource reuse, saving manpower and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following is further described in detail through specific implementation methods:

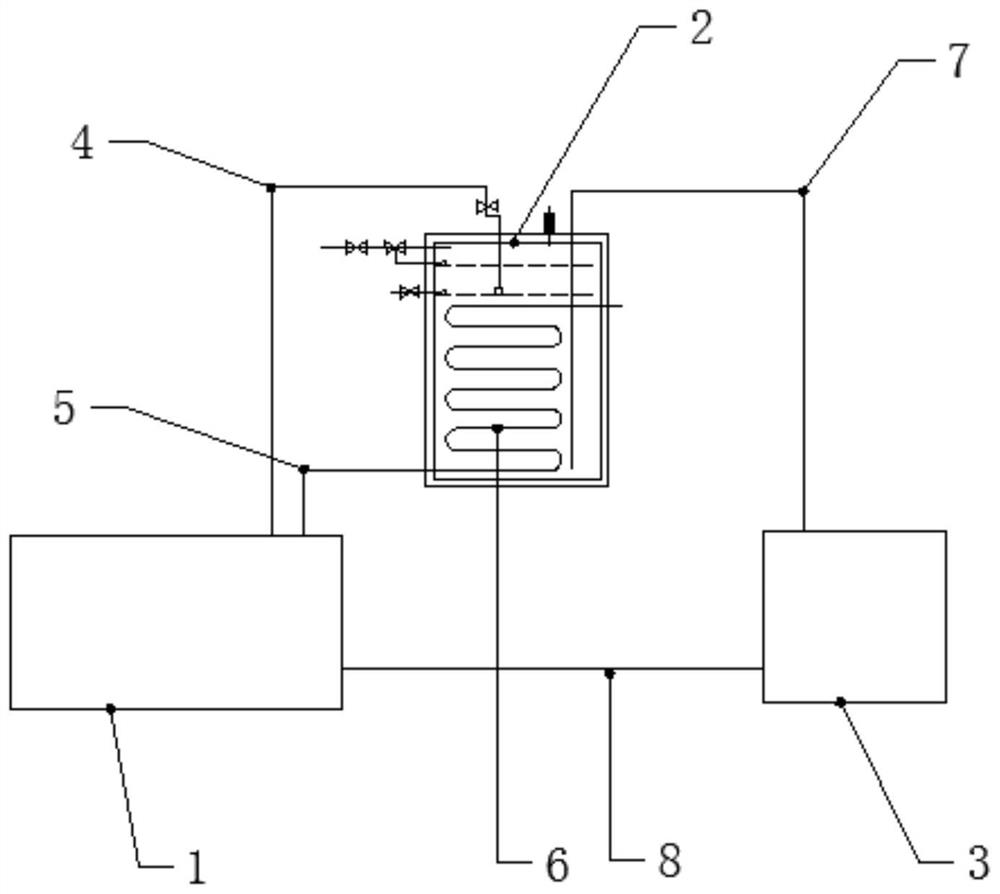

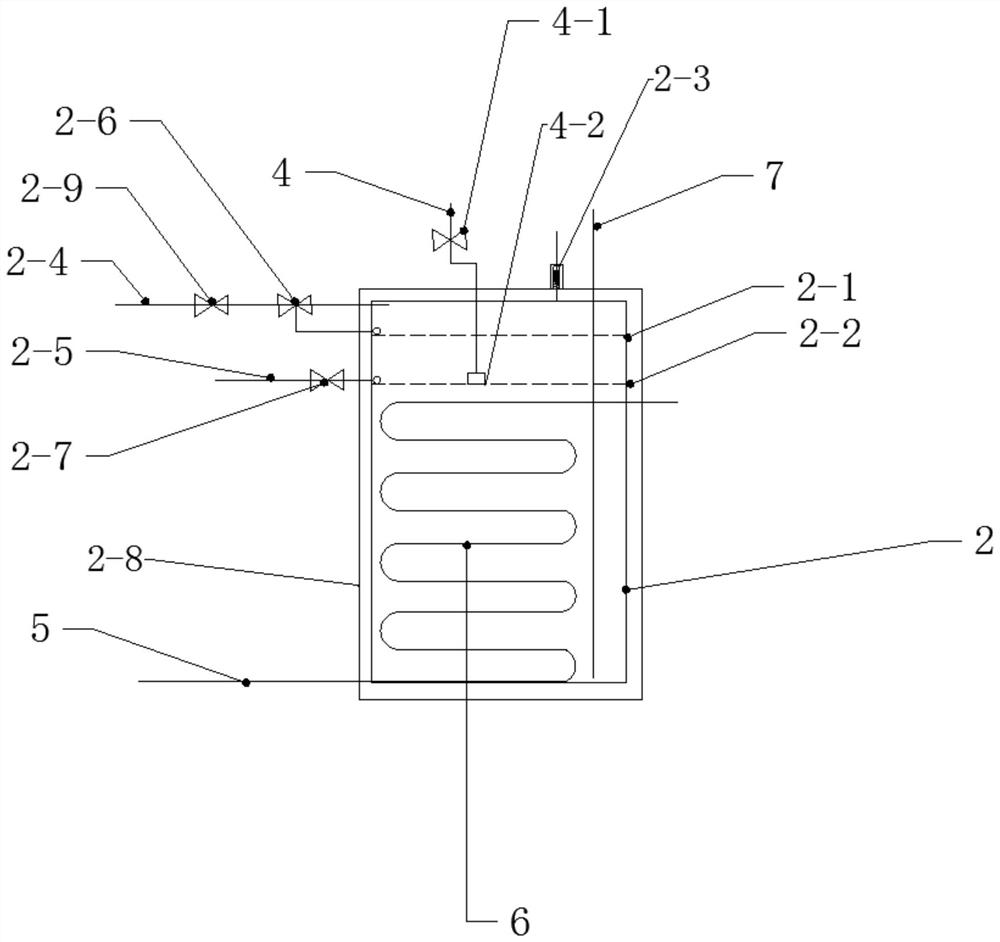

[0016] The reference signs in the drawings of the description include: autoclave 1, water tank 2, boiler 3, residual pressure pipe 4, residual pressure valve 4-1, temperature sensor 4-2, residual heat pipe 5, coil 6, siphon 7, Steam pipe 8, high water level 2-1, low water level 2-2, high pressure stop valve 2-3, water inlet pipe 2-4, air hole 2-5, first ball float valve 2-6, second ball float valve 2-7 , insulation layer 2-8, manual stop valve 2-9.

[0017] The embodiment is basically as attached figure 1 , 2 Shown:

[0018] The specific implementation process is as follows:

[0019] Such as figure 1 , 2 As shown, an aerated brick waste heat and pressure recycling system includes an autoclave 1, a water tank 2, and a boiler 3. One end of the residual pressure pipe 4 and the waste heat pipe 5 is fixedly connected to the autoclave 1, and the other end of the residual pressure pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com