Ultraviolet irradiation crosslinking equipment used in cable production process

A production process, ultraviolet light technology, applied in cable/conductor manufacturing, conductor/cable insulation, circuits, etc., can solve the problems of pollution, slow work efficiency, waste gas escape environment, etc., to avoid environmental pollution and improve environmental protection , The effect of reducing the cumbersome process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

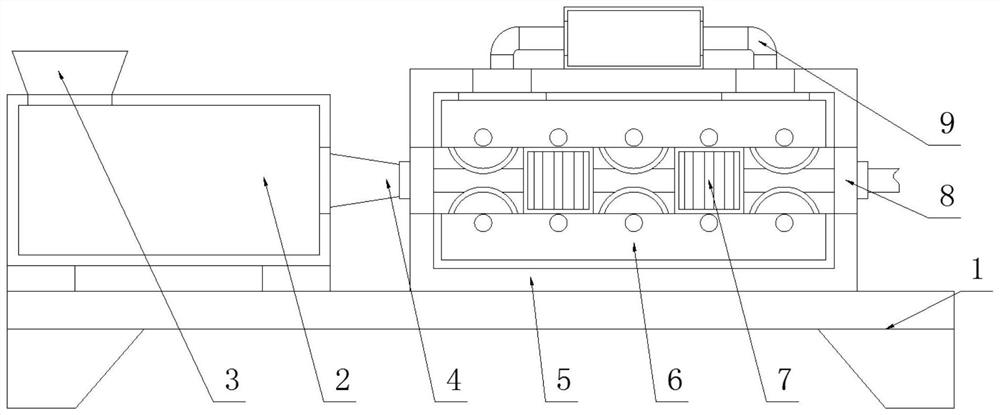

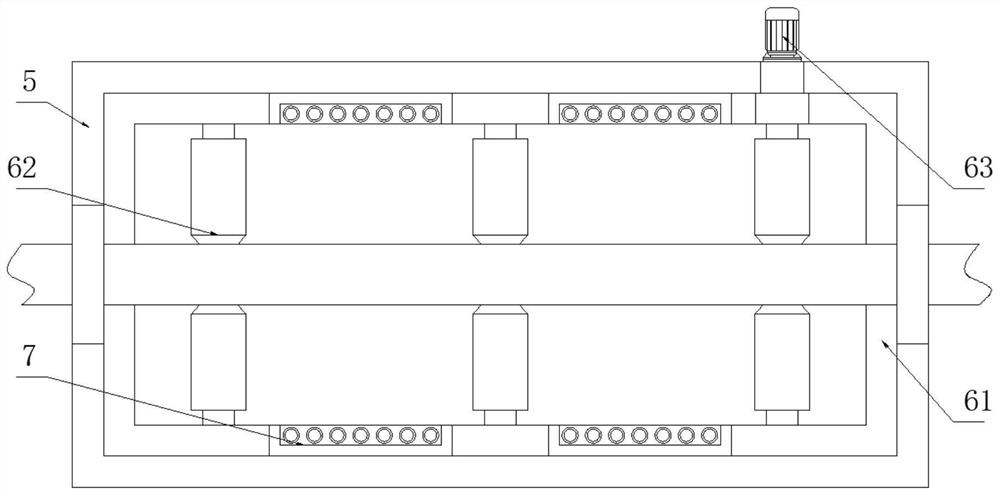

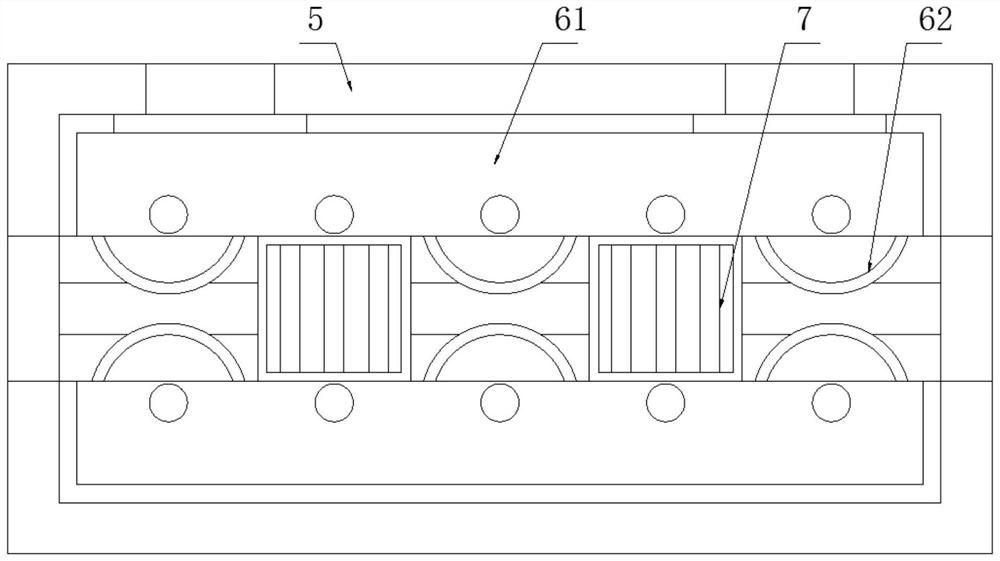

[0020] as attached figure 1 to attach Figure 4 , the embodiment of the present invention provides a kind of ultraviolet radiation cross-linking equipment used in the cable production process, comprising an integrated machine base 1, the left side of the top surface of the integrated machine base 1 is fixedly installed with an extruding unit 2, the extruding unit 2 A feed hopper 3 is fixedly installed on the left side of the top surface, a sealed line pipe 4 is fixedly installed in the middle of the right side of the extrusion unit 2, and the right end of the sealed line pipe 4 is fixedly connected with the top surface of the integrated machine base 1 For the irradiation cabinet 5 that is fixedly connected, the upper and lower sides of the inner cavity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com