Radial and axial composite magnetizing device and magnetizing method for bonded neodymium iron boron magnet ring

A magnetizing device, NdFeB technology, applied in the direction of magnetic objects, electrical components, circuits, etc., can solve the problems of large magnetic ring repulsion, high cost, difficult splicing and assembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is further explained in conjunction with the accompanying drawings.

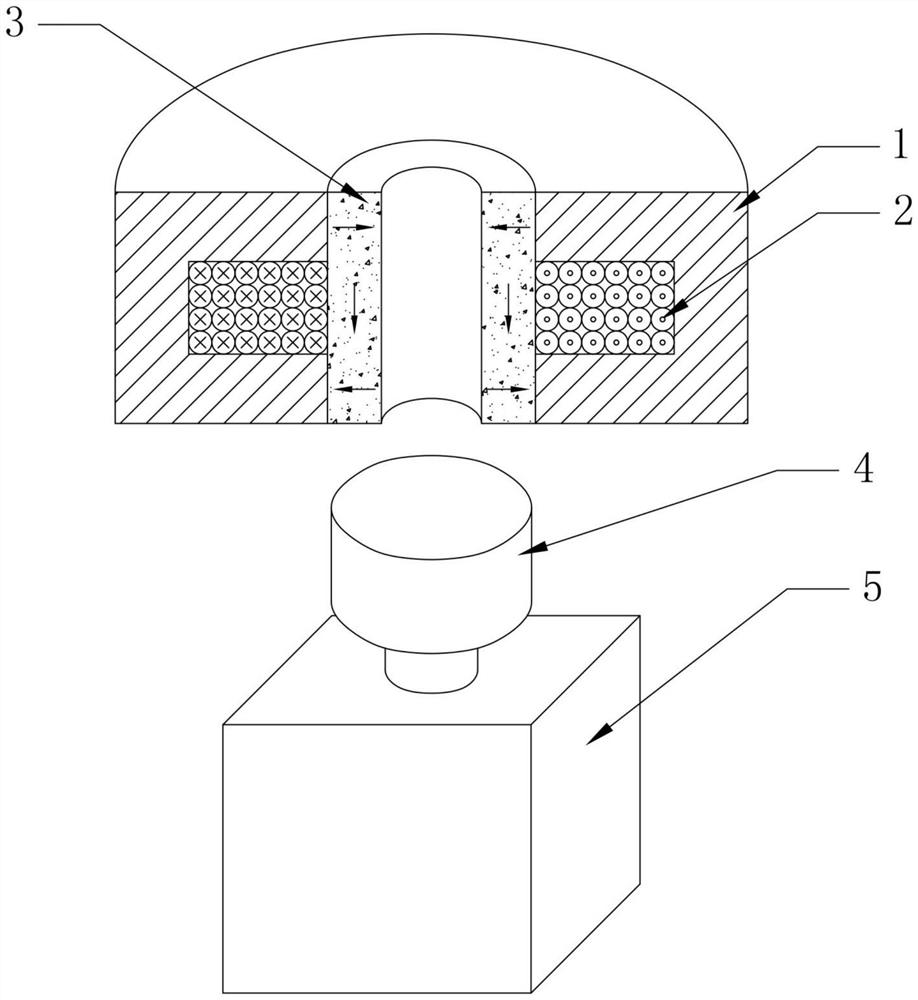

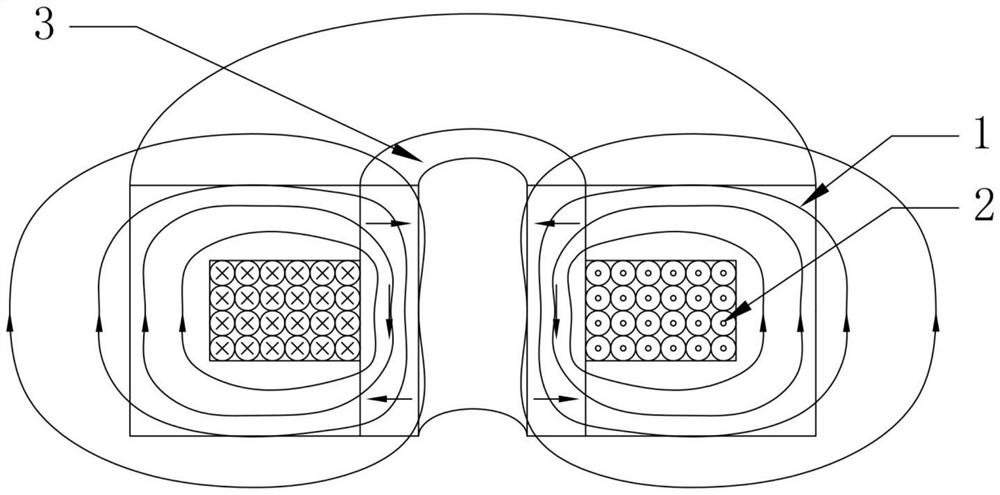

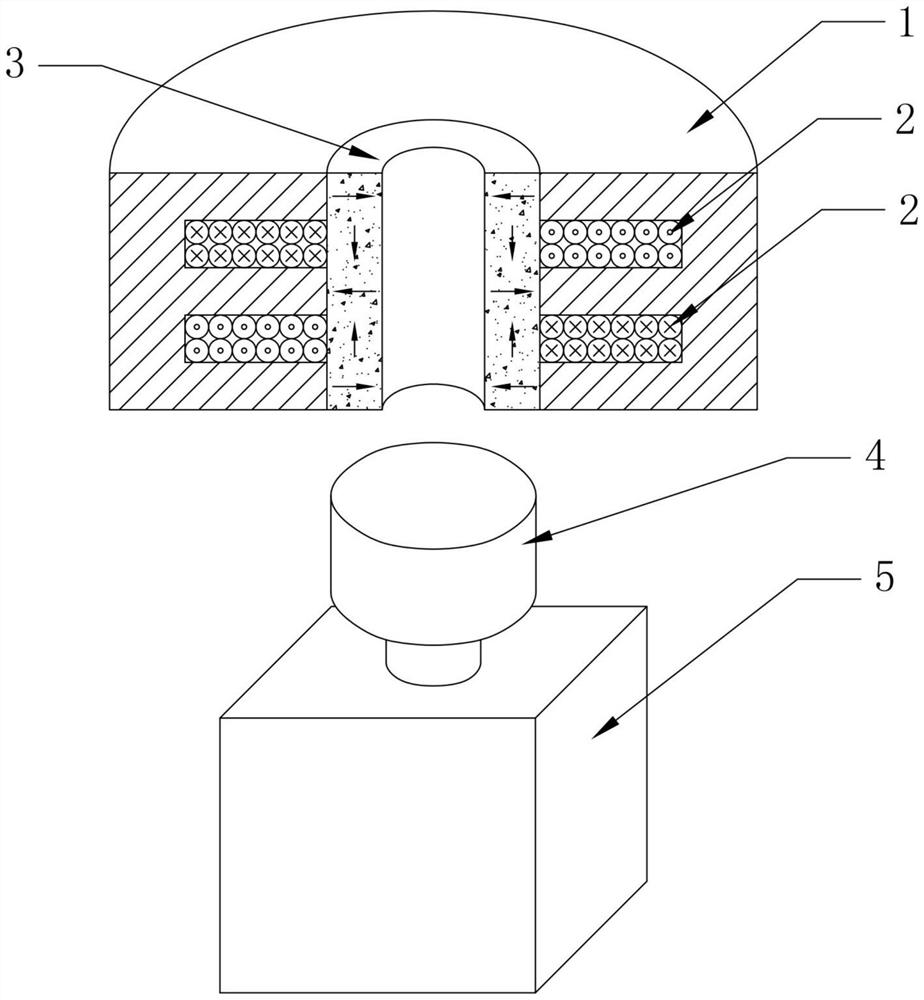

[0034] see Figure 1 to Figure 12 A bonded NdFeB magnetic ring 3 radial and axial composite magnetizing device shown includes a fixture body 1 made of soft magnetic materials, and the materials made of the fixture body 1 include but are not limited to electrical pure iron , carbon steel, silicon steel sheet, permalloy, amorphous soft magnetic and nanocrystalline alloy materials, the fixture body 1 is provided with a ring-shaped groove.

[0035] A magnetizing coil 2 is placed in the slot, the slot is located in the middle of the fixture body 1, and the thickness of the coil is 0.2 to 0.8 times the height of the bonded NdFeB magnetic ring 3 to be magnetized. Coils use insulated wires including but not limited to enameled wires and yarn-covered wires. Materials include but not limited to copper wires and silver wires. The cross-sections of the wires in the coils include but not lim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com