Integrated liquid cooling chip radiator filled with three-period extremely-small curved surface and manufacturing method of integrated liquid cooling chip radiator

A very small curved surface, three-period technology, applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve the problem that liquid-cooled heat sinks are difficult to meet the needs of heat sinks and liquid efficient heat transfer, and eliminate local hot spots. , The heat transfer is uniform and rapid, and the effect of strengthening the convective heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

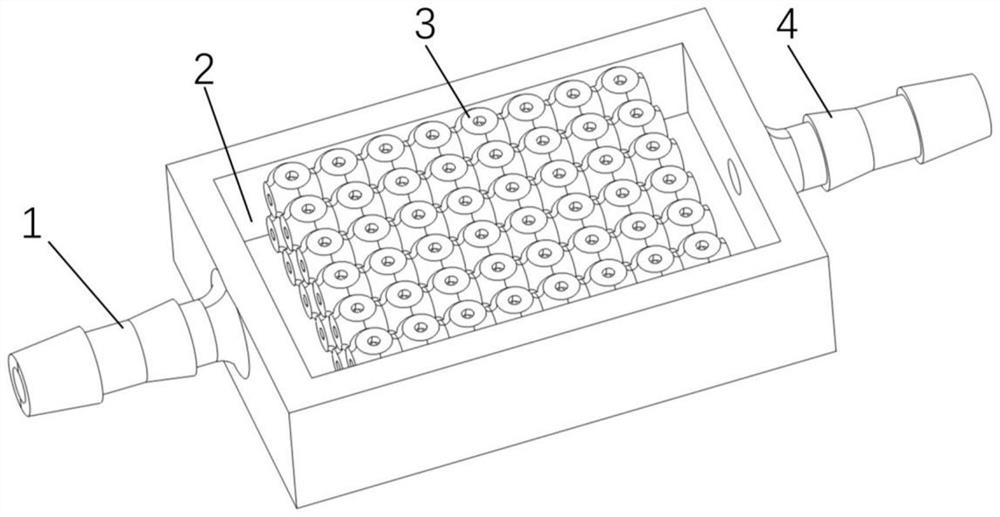

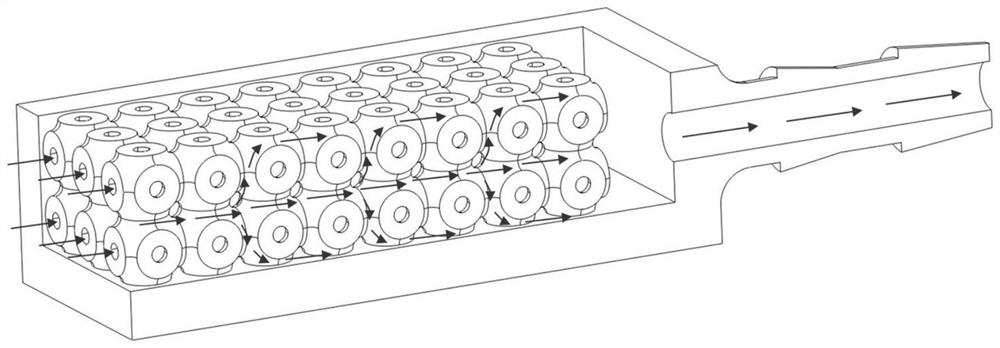

[0031] Such as figure 1 , 5 As shown, this embodiment provides a technical solution: an integrated liquid-cooled chip radiator filled with a three-period minimal curved surface, including: a liquid inlet joint 1, a liquid outlet joint 4, a liquid cooling chamber 2, and a three-period minimal curved surface unit A cell array 3; the three-period minimal curved surface unit cell array 3 is arranged inside the liquid cooling chamber 2, and is integrally formed with the liquid cooling chamber 2 by using an additive manufacturing method. The liquid outlet joint 4, the Liquid inlet joints 1 are arranged at both ends of the liquid cooling chamber 2 .

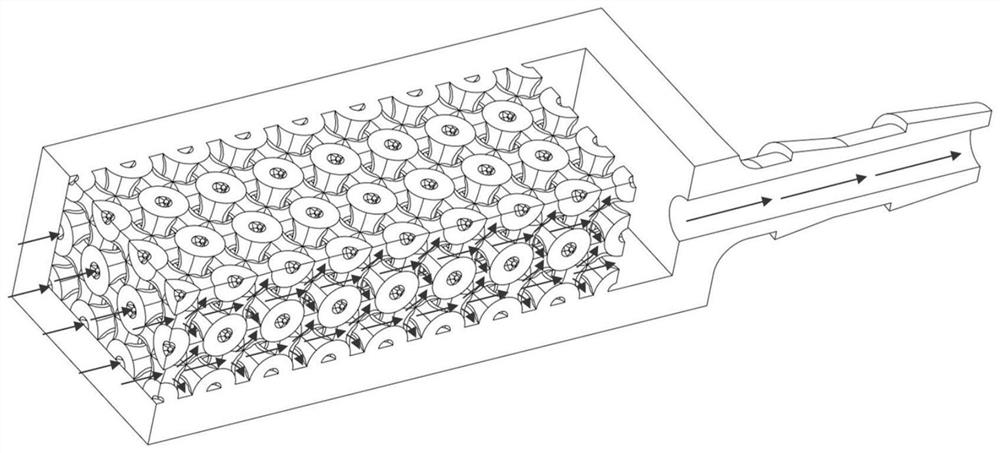

[0032] Furthermore, the three-period minimum surface unit cell array includes a plurality of interconnected three-period minimum surface unit cells, and the three-period minimum surface unit cells include three interconnected curved surfaces, respectively P curved surfaces ( Such as figure 2 shown), I-WP surface (such as image 3 s...

Embodiment 2

[0046] In this embodiment, laser selective melting forming technology is used for preparation, which is suitable for the process flow of the present invention such as Image 6 shown. The first step in the production process is data preparation, which mainly refers to the 3D model suitable for 3D printing, the printing parameters matching the product structure, and the division of the printing program. NX software is used to process the 3D model and optimize the structure; the processed The model uses Magics software for data preparation and printing program generation. Import the prepared data into the 3D printer and start the laser forming process, that is, import the printing program into the 3D printer. After the printer recognizes the program, it converts it into a two-dimensional laser scanning path, and uses the laser as the energy source to print point by point, accumulate layer by layer, and print the product . After the part is formed, the excess powder is removed, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap