Plasma cutting machine with smoke dust collecting and purifying mechanism

A plasma cutting machine, dust collection technology, applied in plasma welding equipment, dust removal, welding equipment, etc., can solve the problems of dust floating everywhere, health problems of workers' smoke and dust, and affecting the surrounding environment, so as to reduce the disassembly time and reduce the impact , The effect of convenient maintenance work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

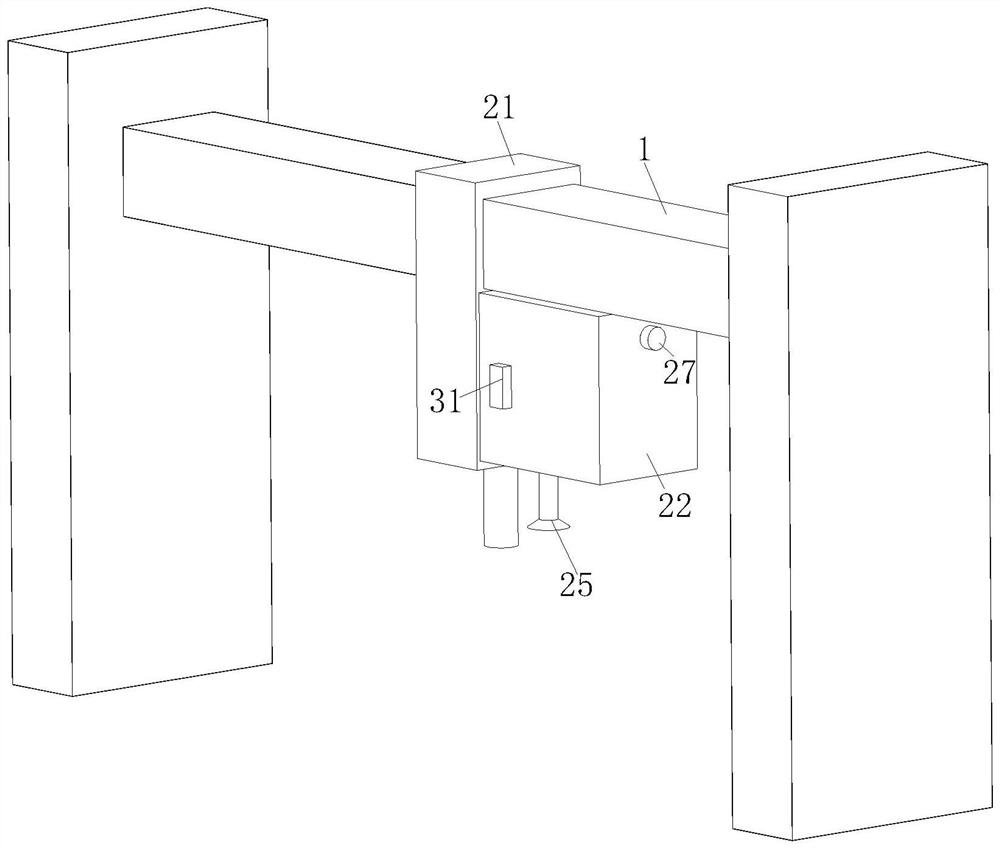

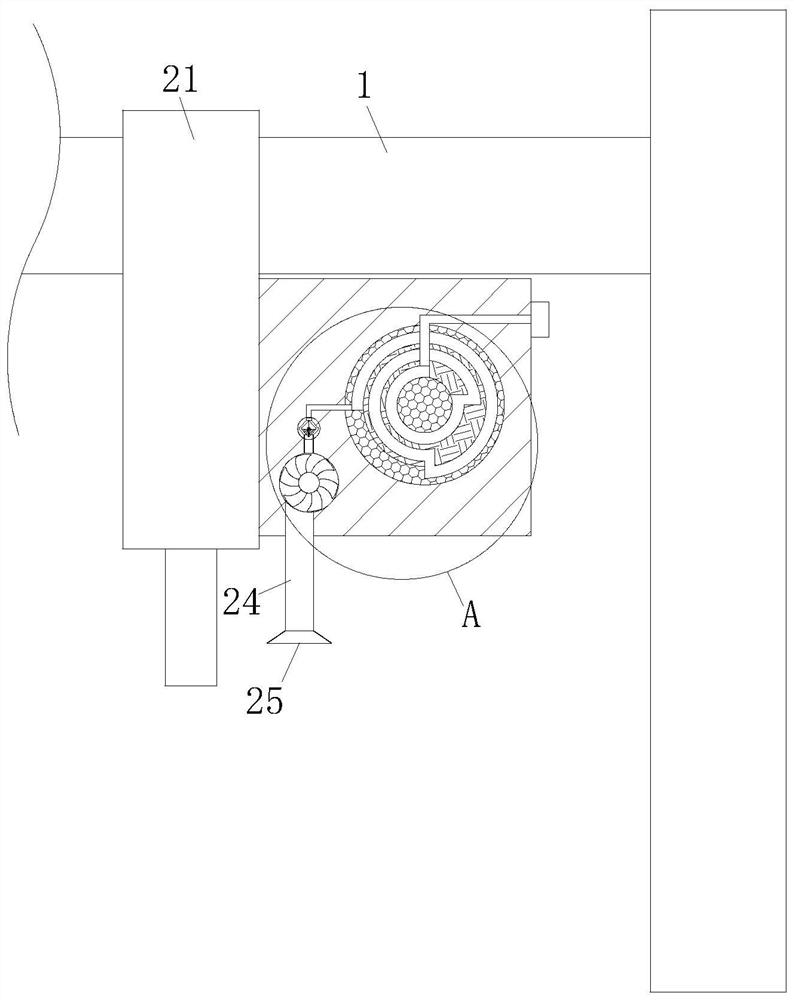

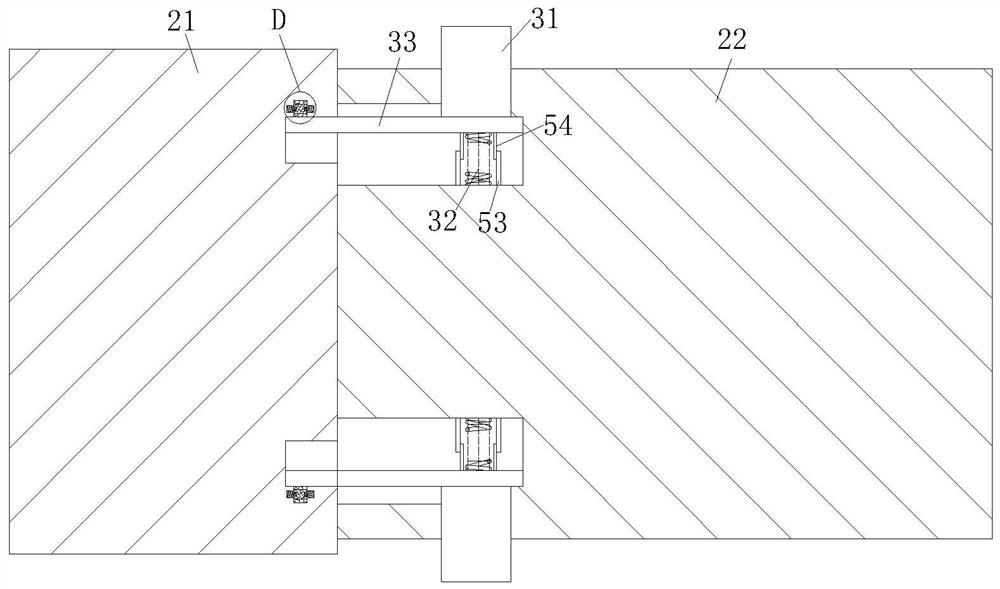

[0028] see Figure 1-7 As shown, a plasma cutting machine provided with a dust collection and purification mechanism includes a body 1; a plasma cutting device 21 is slidably connected to the body 1; a smoking box 22 is installed at the side end of the plasma cutting device 21; The inside of the smoking box 22 is fixedly connected with an exhaust device 23; the bottom end of the smoking box 22 is fixedly connected with a No. 1 smoke pipe 24; the bottom end of the No. 1 smoke tube 24 is fixedly connected with a cigarette tip 25; No. 2 smoke pipe 261 is fixedly connected to the inside of the No. 2 smoke pipe 261; No. 3 smoke pipe 262 is fixedly connected to the top of the No. 2 smoke pipe 261; a filter element 263 is fixedly connected to the inside of the smoking box 22; There is a filter smoke chamber 264; a No. 1 activated carbon 266 is fixedly connected to the inside of the filter element 263; a filter layer 265 is fixedly connected to the inside of the smoking box 22; a smok...

Embodiment 2

[0035] see Figure 8 As shown in Comparative Example 1, as another embodiment of the present invention, the baffle 61 is affixed to the bottom of the cigarette holder 25; The smoke and dust are sucked into the inside of the No. 1 smoke pipe 24, and the dust is filtered by the filter element 263. The blocking object 61 can prevent gas foreign matter from being sucked into the inside of the No. 1 smoke pipe 24 by the air flow, so as to prevent foreign matter from blocking the No. 1 smoke pipe 24 and cause failure.

[0036] Working principle: When working, the plasma cutting device 21 can slide on the body 1 to cut the material. The plasma cutting device 21 will generate a lot of smoke and dust during the cutting process. The negative pressure airflow generated by the exhaust device 23 passes through the No. 1 smoke The pipe 24 sucks the smoke and dust into the cigarette head 25, and the smoke enters the inside of the second smoke pipe 261 through the first smoke pipe 24, so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com