Laser welding pipe plugging device and method for water supply end of high-temperature gas cooled reactor steam generator

A steam generator and high-temperature gas-cooled reactor technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of narrow transportation space and reduce the short-range operation time of operators, so as to improve the degree of automation, The effect of reducing short-range operation time and improving positioning accuracy and welding work accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

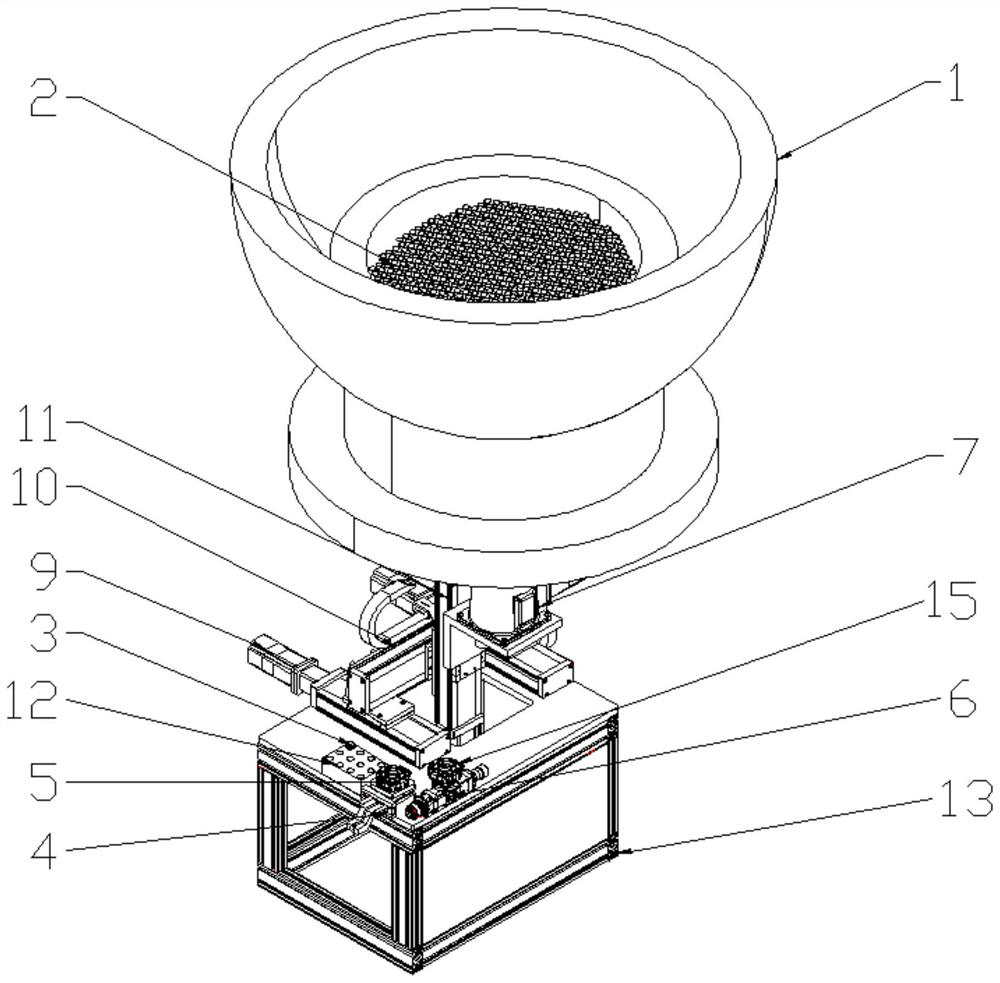

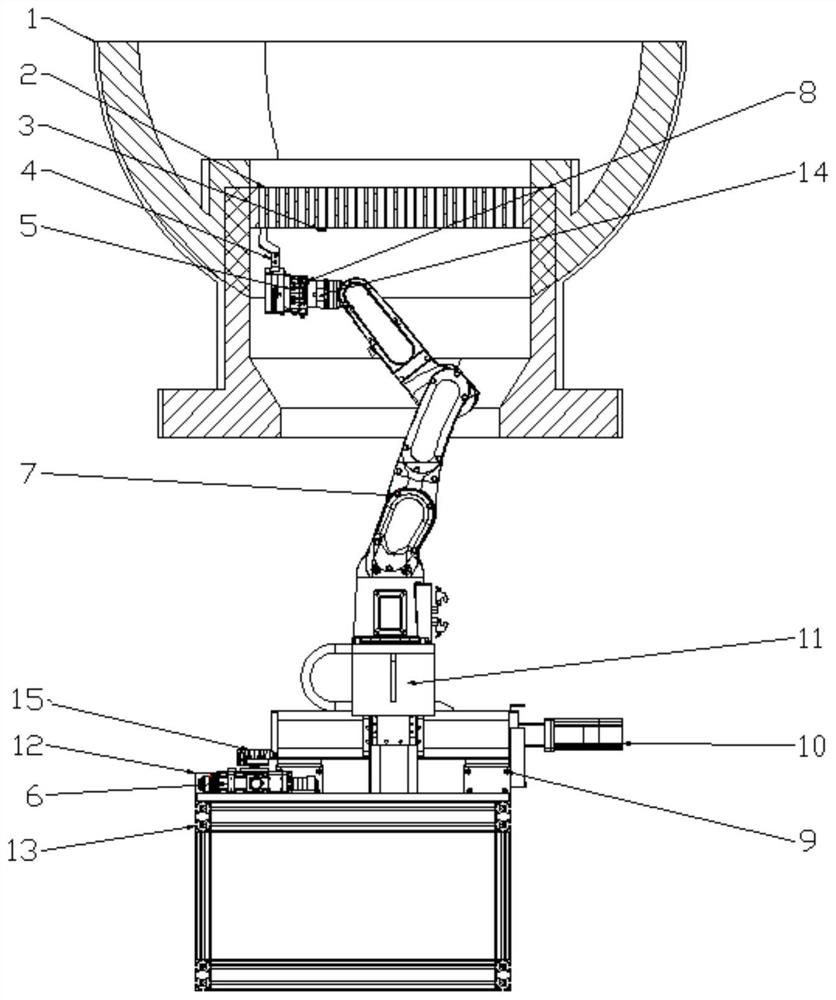

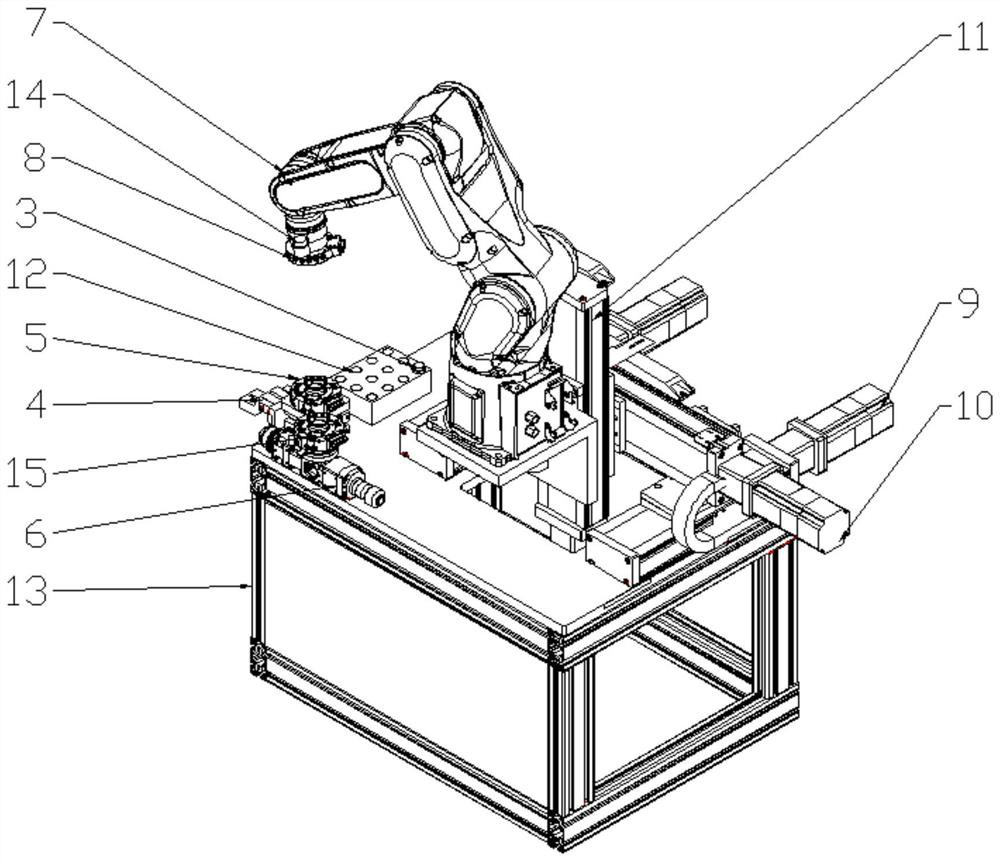

[0024] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the laser welding plugging device at the water supply end of the high temperature gas-cooled reactor steam generator includes a welding plug 3, a multi-axis robot 7, a pneumatic claw 4, a claw quick-change joint 5, a laser head 6, and a robot quick-change joint 8 , X-axis motion mechanism 9, Y-axis motion mechanism 10, Z-axis motion mechanism 11, plug container box 12, support frame 13, camera 14, laser head quick change joint 15;

[0025] The X-axis motion mechanism 9, the Y-axis motion mechanism 10 and the Z-axis motion mechanism 11 form a three-axis motion platform, and are fixed on the support frame 13 through the X-axis motion mechanism 9; the chassis of the multi-axis robot 7 is fixed on the Z-axis The motion mechanism 11 can realize linear motion in the X / Y / Z direction driven by the thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com