Energy storage system and method for preparing methanol by using methanol synthesis waste gas

A technology for synthesizing methanol and energy storage systems, which is applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve the problems of long-term storage, self-discharge loss, high investment cost, etc., to improve energy storage effect, Strong stability and high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

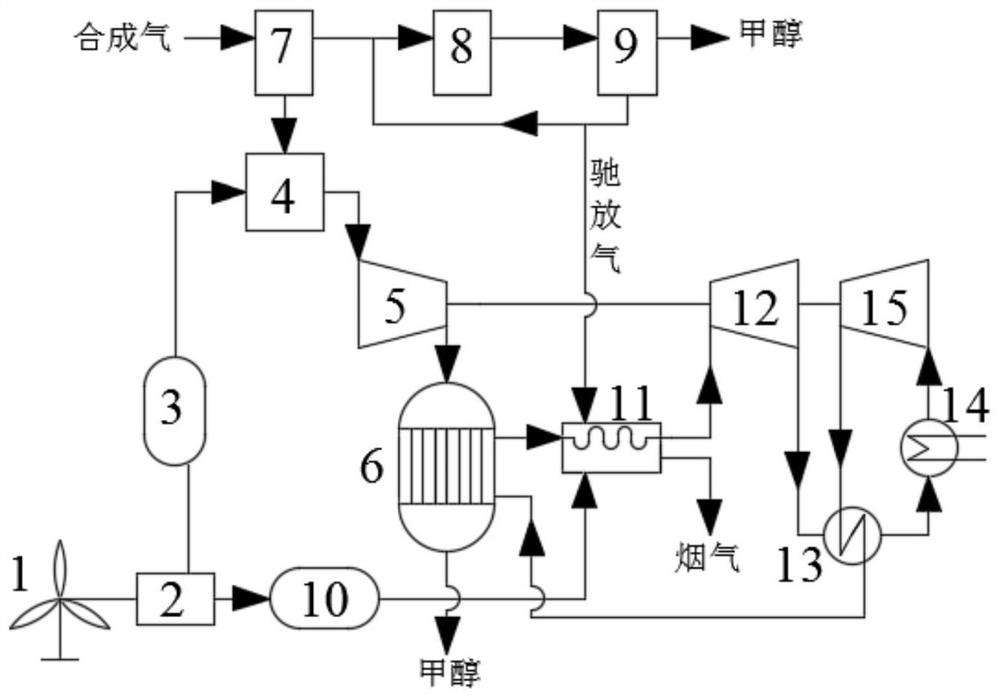

[0031] The present invention is an energy storage system that utilizes synthetic methanol waste gas to produce methanol, such as figure 1 As shown, it includes wind power generation device 1, electrolyzer 2, hydrogen storage tank 3, mixer 4, compressor 5, methanol reactor A 6, decarbonization tower 7, methanol reactor B 8, separation device 9, oxygen storage tank 10. Waste heat boiler 11, turbine 12, regenerator 13, precooler 14, carbon dioxide compressor 15.

[0032] like figure 1 As shown, the hydrogen outlet of the electrolytic cell 2 is connected with the inlet of the reaction end tube side of the methanol reactor A6, and the oxygen outlet of the electrolytic cell 2 is connected with the furnace side inlet of the waste heat boiler 11;

[0033] The input end of the decarburization tower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com