Quartz tube mounting device and mounting method

An installation device and technology for quartz tubes, applied in chemical instruments and methods, electric furnace heating, gaseous chemical plating, etc., can solve the problems of quartz tube frame collision, affecting production costs, time-consuming and laborious installation, etc., to improve accuracy and reduce labor. Strength, damage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

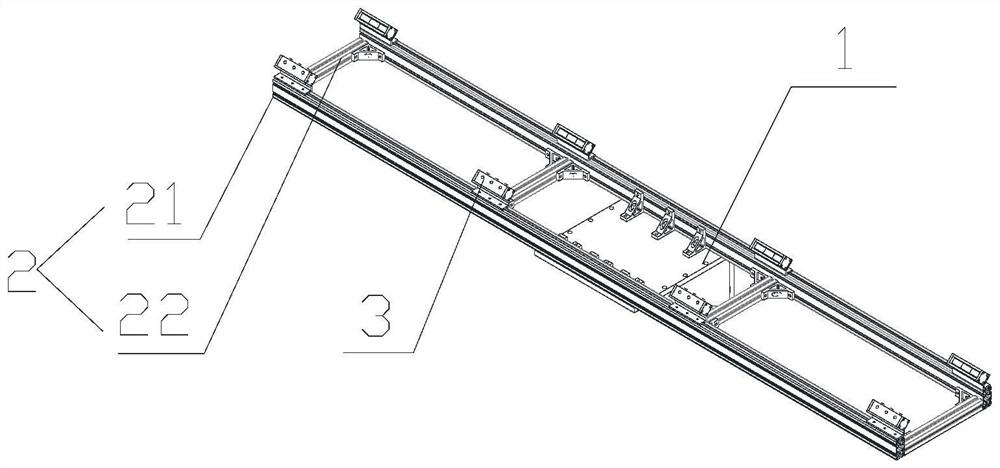

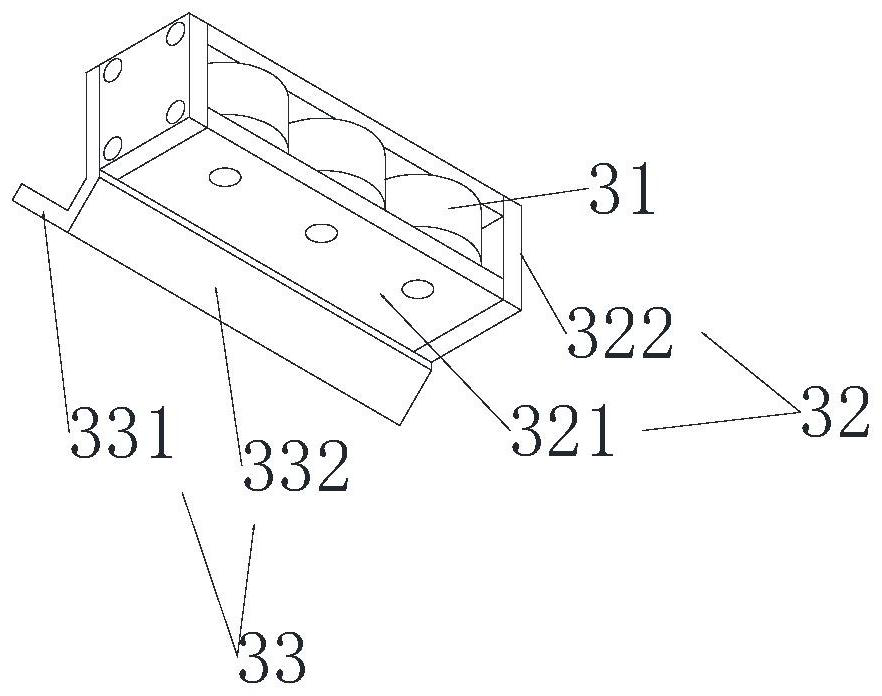

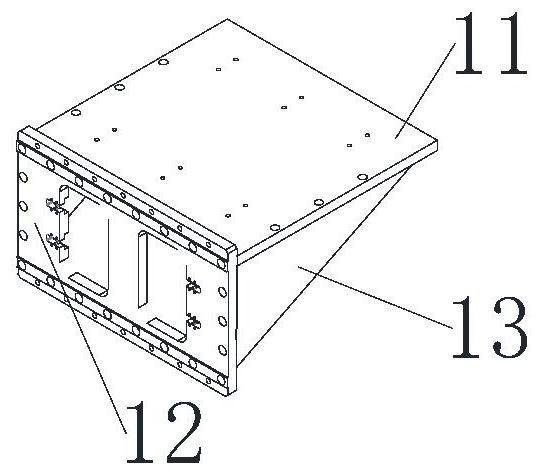

[0039] Such as Figure 1 to Figure 6 As shown, this embodiment discloses a quartz tube installation device, including an installation base 1, a bracket 2 and at least two sliding mechanisms 3, the installation base 1 is arranged under the bracket 2, and the sliding mechanisms 3 are symmetrically arranged on the bracket 2 , the sliding mechanism 3 is used to support and realize the movement of the quartz tube along the bracket 2 .

[0040] It should be noted that the installation device for quartz tubes of the present invention can be used for the installation of quartz tubes in diffusion furnaces, annealing furnaces or PECVD equipment. This type of equipment usually consists of three parts: a source cabinet, a furnace body cabinet and a clean bench. The source cabinet It mainly provides various process gases and liquids required for the process; the reaction chamber is located in the furnace body and is the place for process reaction; the clean table mainly provides loading an...

Embodiment 2

[0053] This embodiment provides a method for installing a quartz tube, using the installation device in Embodiment 1. The method includes the following steps:

[0054] S1, the installation device for assembling the quartz tube;

[0055] S2, connecting the installation device with the boat pushing mechanism;

[0056] S3, installing the quartz tube on the installation device;

[0057] S4. The boat pushing mechanism drives the installation device to move to the furnace mouth;

[0058] S5. Push the quartz tube into the furnace body.

[0059] The installation method of the quartz tube in this implementation adopts an installation device with a simple structure, ingeniously cooperates with the existing push boat mechanism, and realizes the lifting of the quartz tube and sending it to the furnace mouth by means of the push boat mechanism, instead of manual lifting. The quartz tube greatly reduces the labor intensity, reduces the labor cost, and improves the efficiency, especially ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com