High-power microwave effect experimental test method and automatic test system

A high-power microwave and test method technology, applied in the fields of electromagnetic field characteristics, can solve the problems of difficult oscilloscopes, difficult signal analysis, and the evaluation of the damage effect of the DUT without grading and classification, so as to ensure the safety of testing and improve the efficiency of experimental testing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

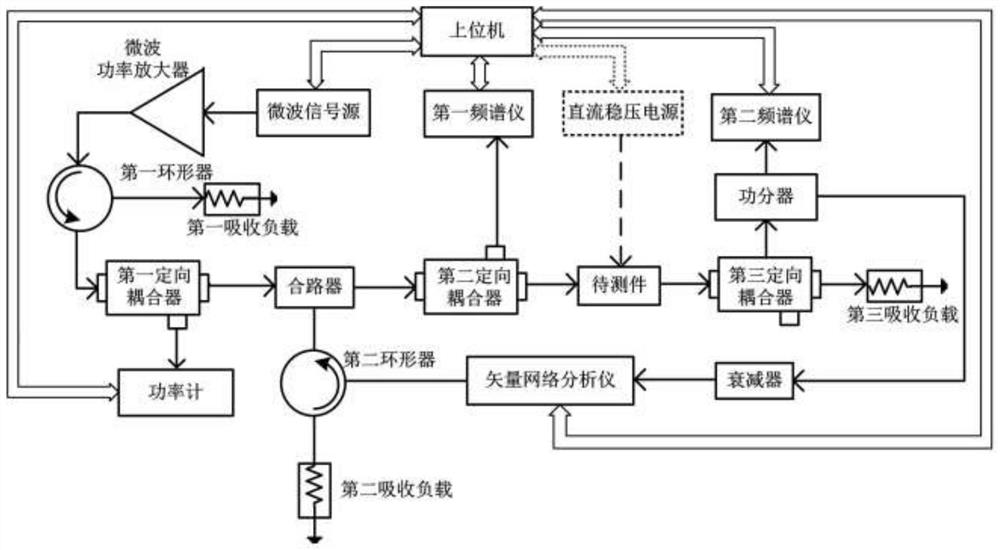

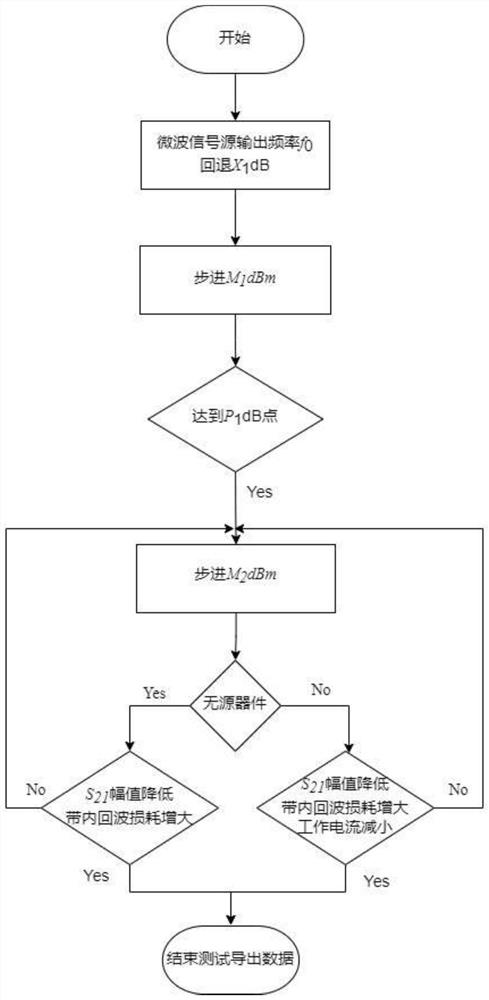

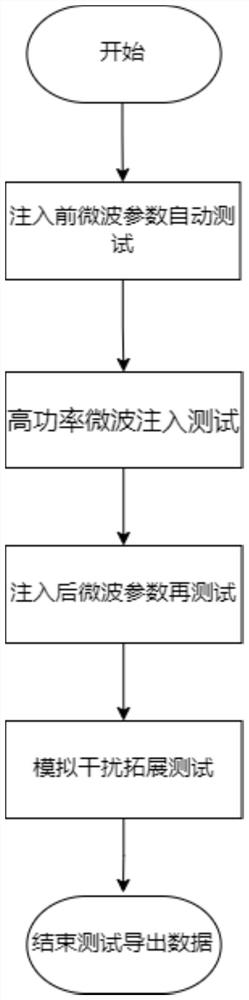

[0035] In order to make the technical solution of the present invention clearer, the present invention will be further described below through specific embodiments in conjunction with the accompanying drawings. This embodiment provides an automatic test system for high-power microwave effect experiments. The system includes: a high-power microwave injection unit, a reflected signal test unit, an S parameter real-time test unit, an output signal test unit, and a host computer.

[0036] The high-power microwave injection unit is used to generate high-power microwave signals, and includes sequentially cascaded microwave signal sources, solid-state microwave power amplifiers, first circulators, first directional couplers, combiners, and power meters.

[0037] The reflected signal testing unit is used for measuring the spectral power component of the reflected signal on the input port surface of the DUT, and includes a second directional coupler and a first spectrum analyzer.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com