Low-GI Chinese pastry premixed flour and product preparation method thereof

A technology of Chinese-style pasta and pre-mixed powder, which is applied in the direction of food science, etc., can solve the problem of single raw material, achieve good taste, delay the peak time of blood sugar, and reduce the effect of GI value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

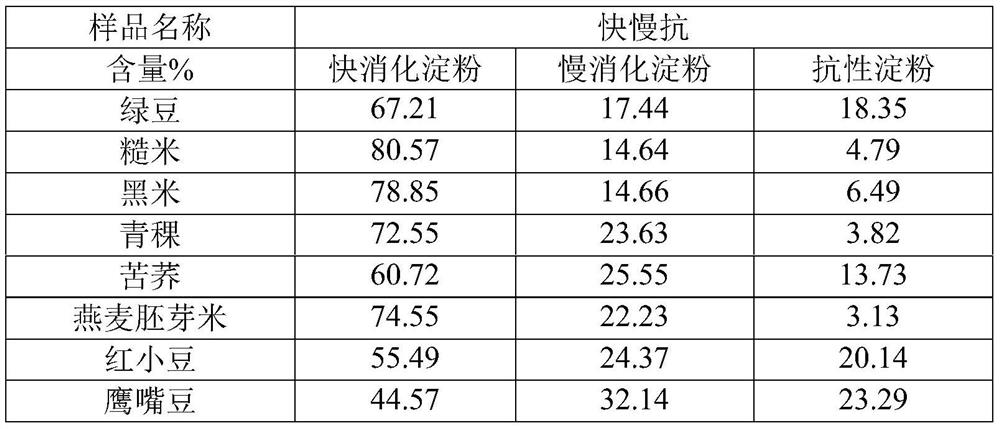

Method used

Image

Examples

Embodiment 1

[0034] 15g of mung bean that has undergone instantaneous rapid high-temperature treatment (170°C, 30s) was crushed to 80 mesh, 10g of tartary buckwheat was crushed to 100 mesh, 15g of highland barley was crushed to 60 mesh, 10g of oat germ rice was crushed to 80 mesh, and rapid high-temperature treatment (150 ℃, 30s) black rice 10g crushed to 40 mesh and mixed, add 40g flour, 20g gluten powder, 3g whey protein powder, 3g milk powder, 2g yeast, and mix well.

[0035] When preparing the product, add 90g of warm water, mix and knead to form a smooth dough. The first fermentation temperature is 32°C, the fermentation time is 40min, and the shape is shaped. The second fermentation temperature is 37°C, the humidity is 85%, and the proofing time is 40min. It can be prepared into low GI steamed buns, low GI bun skins, low GI dumpling skins, low GI biscuits, low GI pancakes and other Chinese pastries.

Embodiment 2

[0037] After rapid high-temperature treatment (195°C, 30s), 15g of red bean was crushed to 60 mesh, 10g of tartary buckwheat was crushed to 100 mesh, 15g of highland barley was crushed to 60 mesh, 10g of oat germ rice was crushed to 80 mesh, and rapid high-temperature treatment (150 ℃, 30s) of black rice 10g crushed to 60 mesh and mixed, add 40g of flour, 20g of gluten powder, 3g of whey protein powder, 3g of milk powder, 2g of yeast, and mix well.

[0038] When preparing the product, add 90g of warm water, mix and knead to form a smooth dough. The first fermentation temperature is 32°C, the fermentation time is 40min, and the shape is shaped. The second fermentation temperature is 37°C, the humidity is 85%, and the proofing time is 40min. It can be prepared into low GI steamed buns, low GI bun skins, low GI dumpling skins, low GI biscuits, low GI pancakes and other Chinese pastries.

Embodiment 3

[0040] 5g of brown rice after rapid high temperature treatment (120°C, 30s) was crushed to 40 mesh, 15g of mung bean (170°C, 30s) was crushed to 80 mesh, 10g of black rice after rapid high temperature treatment (150°C, 30s) was crushed to 40 mesh, Crush 10g of tartary buckwheat to 100 mesh, crush 15g of highland barley to 60 mesh, crush 15g of oat germ rice to 80 mesh, add 40g of flour, 20g of gluten powder, 5g of whey protein powder, 4g of milk powder, and 1.5g of yeast, and mix well .

[0041] When preparing the product, add 90g of warm water, mix and knead to form a smooth dough. The first fermentation temperature is 32°C, the fermentation time is 40min, and the shape is shaped. The second fermentation temperature is 37°C, the humidity is 85%, and the proofing time is 40min. It can be prepared into low GI steamed buns, low GI bun skins, low GI dumpling skins, low GI biscuits, low GI pancakes and other Chinese pastries.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com