Medical composite material as well as preparation method and application thereof

A composite material and medical technology, applied in the field of medical composite materials and their preparation, can solve problems such as difficulty in taking into account the stability of bending strength, elastic modulus and mechanical properties, avoid rapid loss of mechanical properties, low melting temperature, and improve stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

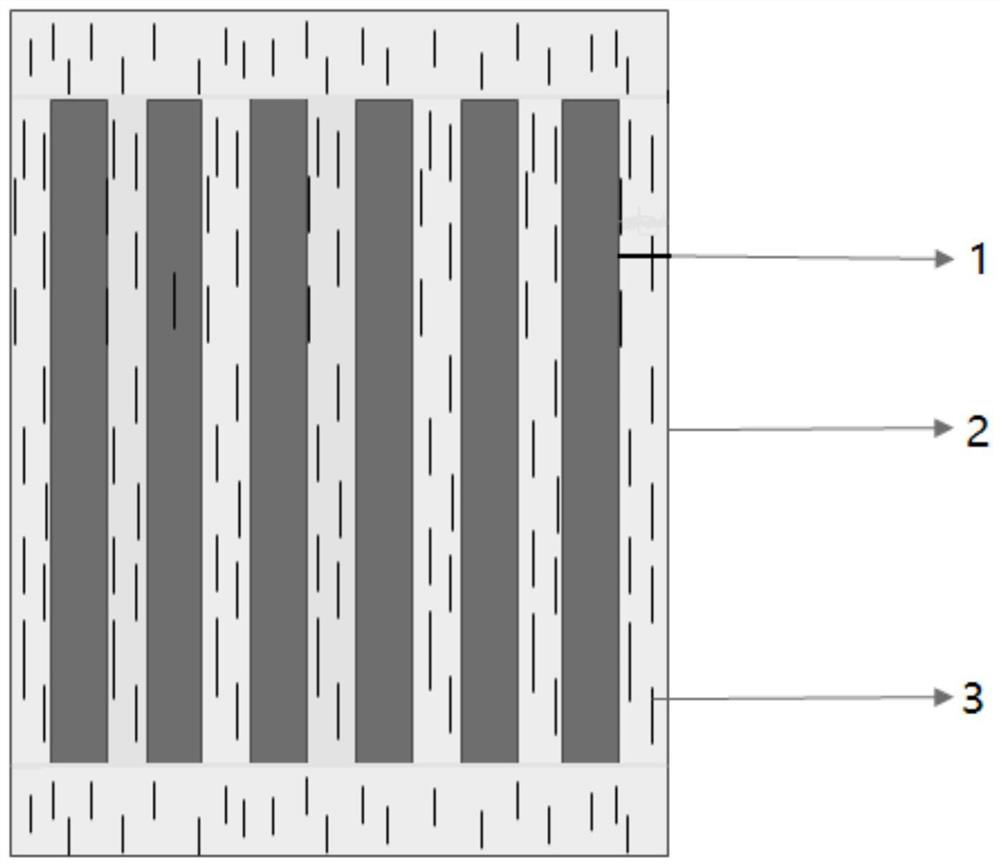

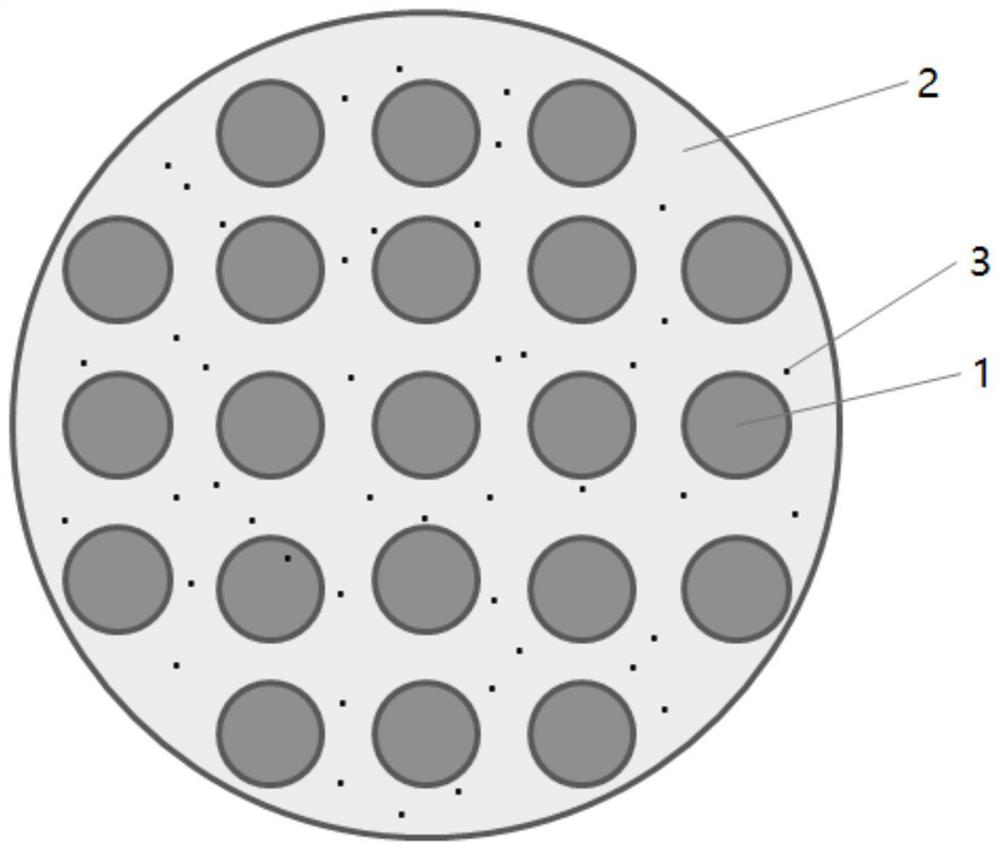

[0052] This embodiment provides a medical composite material with a structure such as figure 1 (1 is the first polymer thread, 2 is the second polymer, and 3 is the bioactive glass fiber), the preparation method is as follows:

[0053] Add 35 parts by mass of bioactive phosphate glass fiber (bioactive glass fiber), 5 parts by mass of the second polymer PCL polymer, 100 parts by mass of acetone, and 40 parts by mass of zirconium beads into the dispersion tank. After dispersing and shearing for 2 hours, filter the zirconium beads to obtain solution A; put the first polymer L-polylactic acid thread into solution A to infiltrate, dry with hot air, and then pull it into a conical device for pultrusion (pultrusion The line speed is 0.11m / min). In the drawn melt (65°C), the mass ratio of bioactive phosphate glass fiber to PCL was 5:3. The pultruded and cooled material filaments were cut into 10 cm lengths to obtain composite material monomers. Align 1000 obtained composite materia...

Embodiment 2

[0055] This embodiment provides a medical composite material with a structure such as figure 1 (1 is the first polymer thread, 2 is the second polymer, and 3 is the bioactive glass fiber), the preparation method is as follows:

[0056] Add 38 parts by mass of bioactive phosphate glass fiber (bioactive glass fiber), 4 parts by mass of the second polymer PCL polymer, 100 parts by mass of acetone, and 40 parts by mass of zirconium beads into the dispersion tank. After dispersing and shearing for 2 hours, filter the zirconium beads to obtain solution A; put the first polymer L-polylactic acid thread into solution A to infiltrate, dry with hot air, and then pull it into a conical device for pultrusion (pultrusion The line speed is 0.08m / min). In the pulled melt (60°C), the mass ratio of bioactive phosphate glass fiber to PCL was 7:1. The pultruded and cooled material filaments were cut into 10 cm lengths to obtain composite material monomers. Take 5,000 obtained composite materi...

Embodiment 3

[0058] This embodiment provides a medical composite material with a structure such as figure 1 (1 is the first polymer thread, 2 is the second polymer, and 3 is the bioactive glass fiber), the preparation method is as follows:

[0059] Add 32 parts by mass of bioactive phosphate glass fiber (bioactive glass fiber), 6 parts by mass of the second polymer PCL polymer, 100 parts by mass of acetone (solvent), and 40 parts by mass of zirconium beads (grinding beads) into the dispersion tank. After dispersing and shearing for 2 hours, filter the zirconium beads to obtain solution A; put the first polymer L-polylactic acid thread into solution A to infiltrate, dry with hot air, and then pull it into a conical device for pultrusion (pultrusion The line speed is 0.15m / min). In the pulled melt (100°C), the mass ratio of bioactive phosphate glass fiber to PCL was 3:5. The pultruded and cooled material filaments were cut into 10 cm lengths to obtain composite material monomers. Take 500...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com