High-frequency induction seamless special-shaped titanium welded pipe and production method

A seamless special-shaped, high-frequency induction technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of high cost, inability to pass rolling, low precision of fusion welding process, etc., to reduce production costs , uniform wall thickness and outer diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

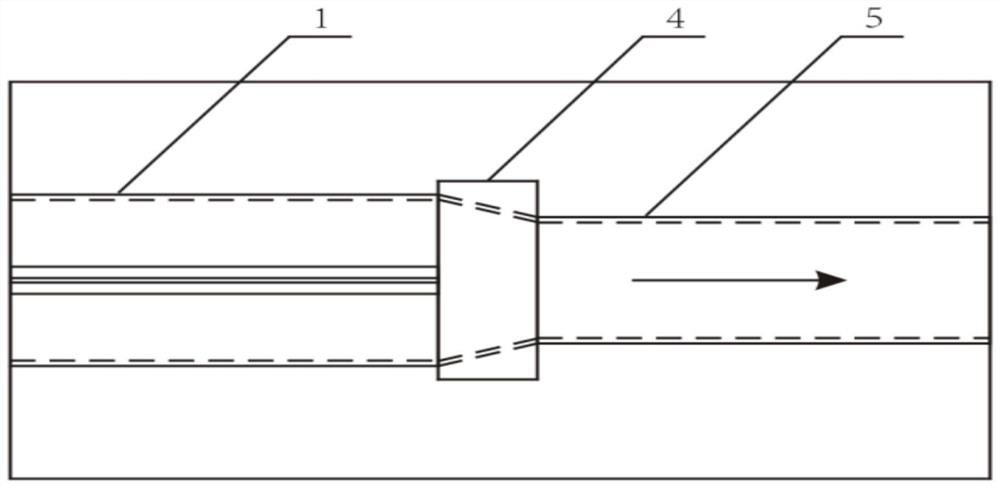

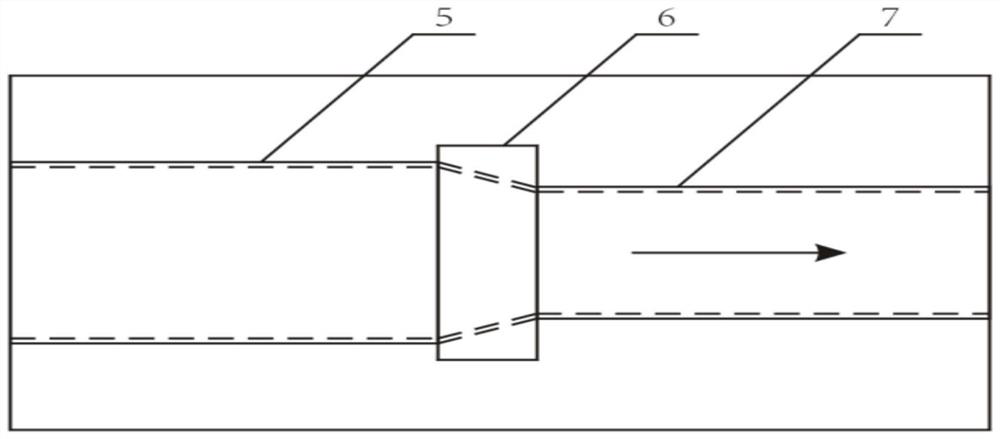

[0034] The present invention proposes a high-frequency induction seamless special-shaped titanium welded pipe. After the parent pipe 1 undergoes the first pass of Czochralski cold drawing and shrinkage, the second pass of special-shaped pipe preformed Czochralski cold drawing and heat treatment, and then passes through The special-shaped tube is finely formed in the third pass, straight-drawn and cold-drawn, and finally made by hydraulic shaping of the inner core.

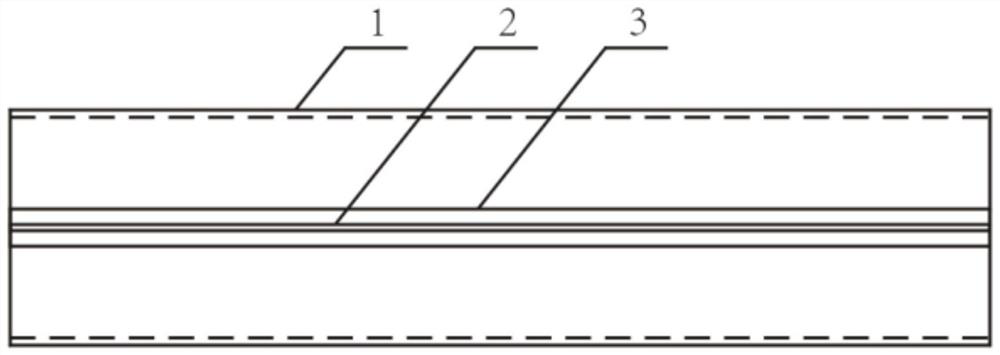

[0035] like figure 1 As shown, the parent pipe 1 is a high-frequency induction straight seam welded titanium pipe with internal and external scratches; the original weld seam 2 on the appearance surface of the prepared seamless special-shaped titanium welded pipe 12 is invisible after polishing, the wall thickness and outer diameter are uniform, and the original weld seam 2 and heat-affected zone 3 in the longitudinal direction and circumferential direction, the microstructure and properties are consistent with the...

Embodiment 2

[0045] The present invention proposes a high-frequency induction seamless special-shaped titanium welded pipe. After the parent pipe 1 undergoes the first pass of Czochralski cold drawing and shrinkage, the second pass of special-shaped pipe preformed Czochralski cold drawing and heat treatment, and then passes through The special-shaped tube is finely formed in the third pass, straight-drawn and cold-drawn, and finally made by hydraulic shaping of the inner core.

[0046] like figure 1 As shown, the parent pipe 1 is a high-frequency induction straight seam welded titanium pipe with internal and external scratches; the original weld seam 2 on the appearance surface of the prepared seamless special-shaped titanium welded pipe 12 is invisible after polishing, the wall thickness and outer diameter are uniform, and the original weld seam 2 and heat-affected zone 3 in the longitudinal direction and circumferential direction, the microstructure and properties are consistent with the...

Embodiment 3

[0065] The present invention proposes a high-frequency induction seamless special-shaped titanium welded pipe. After the parent pipe 1 undergoes the first pass of Czochralski cold drawing and shrinkage, the second pass of special-shaped pipe preformed Czochralski cold drawing and heat treatment, and then passes through The special-shaped tube is finely formed in the third pass, straight-drawn and cold-drawn, and finally made by hydraulic shaping of the inner core.

[0066] like figure 1 As shown, the parent pipe 1 is a high-frequency induction straight seam welded titanium pipe with internal and external scratches; the original weld seam 2 on the appearance surface of the prepared seamless special-shaped titanium welded pipe 12 is invisible after polishing, the wall thickness and outer diameter are uniform, and the original weld seam 2 and heat-affected zone 3 in the longitudinal direction and circumferential direction, the microstructure and properties are consistent with the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com