Preparation method of fuming material for aroma-retaining slow-release heating cigarettes

A slow-release, cigarette technology, which is applied in the preparation of tobacco, application, tobacco, etc., can solve the problems of decreased experience, sharp attenuation of smoke and aroma, etc., and achieve the effect of reducing the rate of attenuation by mouth and improving sensory experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for preparing a smoking material for flavor-preserving and slow-release heated cigarettes. According to the mass ratio, 70% of peach gum powder, 20% of red tobacco paste, 5% of glycerin, and 5% of propylene glycol are mixed, heated to 60°C and Stir evenly to obtain a slow-release feed liquid; mix 80% of tobacco leaf powder, tobacco rod fiber 15%, and carboxymethyl cellulose 5% of 60 mesh NC297 tobacco evenly to obtain tobacco mixed powder; prepare slow-release feed liquid and Tobacco mixed powder is mixed and stirred evenly according to the mass ratio of 70%:30%. After adjusting the moisture according to the requirements of the molding equipment, the thick slurry is made into tobacco sheets by rolling method, and then the tobacco sheets are dried to a moisture content of 12%. Flavor-preserving slow-release smoking material for heated cigarettes.

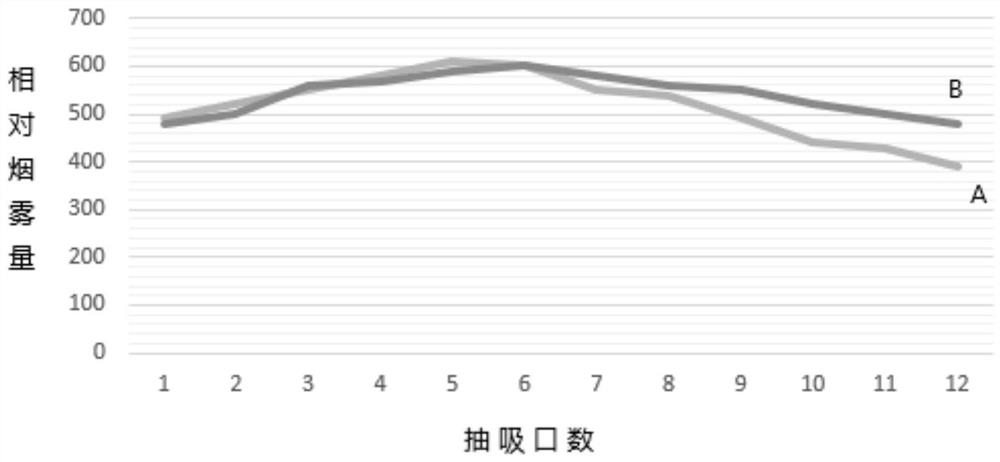

[0023] The smoking material for the sheet-shaped flavor-preserving and slow-release heating cigarette prepared in t...

Embodiment 2

[0026] A method for preparing a smoking material for flavor-preserving and slow-release heated cigarettes. According to the mass ratio, 20% of peach gum powder, 70% of konjac gum powder, 5% of black tea extract, and 5% of propylene glycol are mixed, and heated to 65°C and stir evenly to obtain a slow-release feed liquid; mix 60% of tobacco leaf powder, 10% of tobacco stem powder, 15% of wood pulp fiber, and 15% of carboxymethyl cellulose of 80-mesh K326 tobacco to obtain tobacco mixed powder; prepare A good slow-release material liquid and tobacco mixed powder are mixed and stirred evenly according to the mass ratio of 80%: 20%. After adjusting the water according to the requirements of the molding equipment, the thick slurry is used to make the thick slurry into tobacco sheets, and then the tobacco sheets are dried to The moisture content is 14%, that is, a sheet-like smoking material for flavor-preserving and slow-release heated cigarettes is obtained.

Embodiment 3

[0028] A preparation method of a smoking material for flavor-preserving and slow-release heating cigarettes, comprising 10% of sodium alginate powder, 20% of pullulan powder, 10 parts of alginic acid powder, 20% of Peru net paste, and glycerin according to the mass ratio 20% alcohol and 20% propylene glycol are mixed, heated to 55°C and stirred evenly to obtain a slow-release feed liquid; the slow-release feed liquid is added to the pre-prepared tobacco sheet base by the coating method of the prior art, and then dried Dry until the water content is 10%, and then obtain a sheet-like smoking material for flavor-preserving and slow-release heated cigarettes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com