Technical process for treating peculiar smell produced by animals died of illness

A technology for the treatment of dead animals and odors, which is applied in the directions of using liquid separators, dispersed particle separation, chemical instruments and methods, etc. The effect of exhaust gas removal rate, reduction of purification load, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

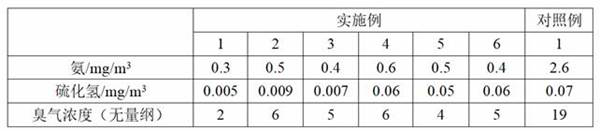

Examples

Embodiment 1

[0020] A technical process for the treatment of peculiar smell produced by dead animals, the treatment process comprising the following steps:

[0021] 1) Pretreatment cooling process

[0022] The vacuum exhaust gas from the sick and dead animals is guided to the water washing tower at 78 ° C, and the sewage treatment 30 ° C clear water pool is used as the cooling water source. The water washing tower uses the secondary atomization device to cool the tail gas, reduce dust, remove oil and absorb water-soluble organic matter. Treatment: After the tail gas is washed by an acid scrubber with a pH of 4 and an alkali scrubber with a pH of 10, the tail gas is guided to the pretreatment enrichment device after demisting;

[0023] (2) Pretreatment enrichment process

[0024] After being washed and demisted by the alkali scrubber, the tail gas is guided to the pretreatment enrichment device. The pretreatment device consists of a 20cm sandstone layer, a 20cm ceramic fiber layer, a 15cm ...

Embodiment 2

[0028] A technical process for the treatment of peculiar smell produced by dead animals, the treatment process comprising the following steps:

[0029] 1) Pretreatment cooling process

[0030] The vacuum exhaust gas from the sick and dead animals is guided to the water washing tower at 50°C, and the 30°C clear water pool for sewage treatment is used as the cooling water source. Treatment: After the tail gas is washed by an acid scrubber with a pH of 2 and an alkali scrubber with a pH of 9, the tail gas is guided to the pretreatment enrichment device after demisting;

[0031] (2) Pretreatment enrichment process

[0032] The tail gas after being washed and demisted by the alkali scrubber is led to the pretreatment enrichment device. The upper part of the device is equipped with biological bacteria liquid and spray plant liquid atomization;

[0033] (3) Palladium carbon catalytic oxidation process

[0034] The tail gas after demisting by the pretreatment enrichment device is ...

Embodiment 3

[0036] A technical process for the treatment of peculiar smell produced by dead animals, the treatment process comprising the following steps:

[0037] 1) Pretreatment cooling process

[0038] The vacuum exhaust gas from the sick and dead animals is guided to the water washing tower at 90°C, and the 30°C clear water pool for sewage treatment is used as the cooling water source. Treatment: After the tail gas is washed by an acid scrubber with a pH of 6 and an alkali scrubber with a pH of 13, the tail gas is guided to the pretreatment enrichment device after demisting;

[0039] (2) Pretreatment enrichment process

[0040] The tail gas after being washed and demisted by the alkali scrubber is led to the pretreatment enrichment device. The pretreatment device consists of a 25cm sandstone layer, a 20cm ceramic fiber layer, a 20cm diatomite layer and a 50cm activated carbon layer from bottom to top. The upper part of the device is equipped with biological bacteria liquid and spray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com