Fixed bed process desulfurizing tower capable of heating and dehumidifying

A technology for heating dehumidification and desulfurization towers, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc. It can solve the problems of inability to adjust the working state of heating pipes in real time, complicated layout of heating pipes, and reduction of the number of interfaces, so as to reduce welding Workload, the effect of reducing the space occupied by pipes, and reducing the number of interfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

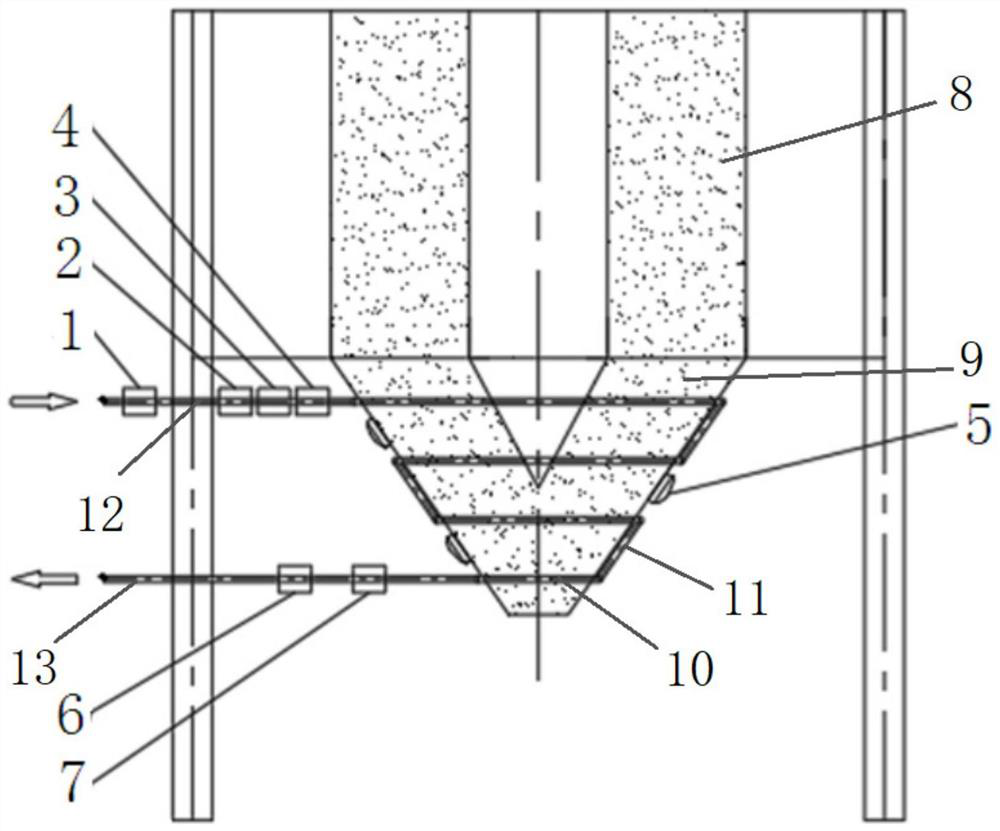

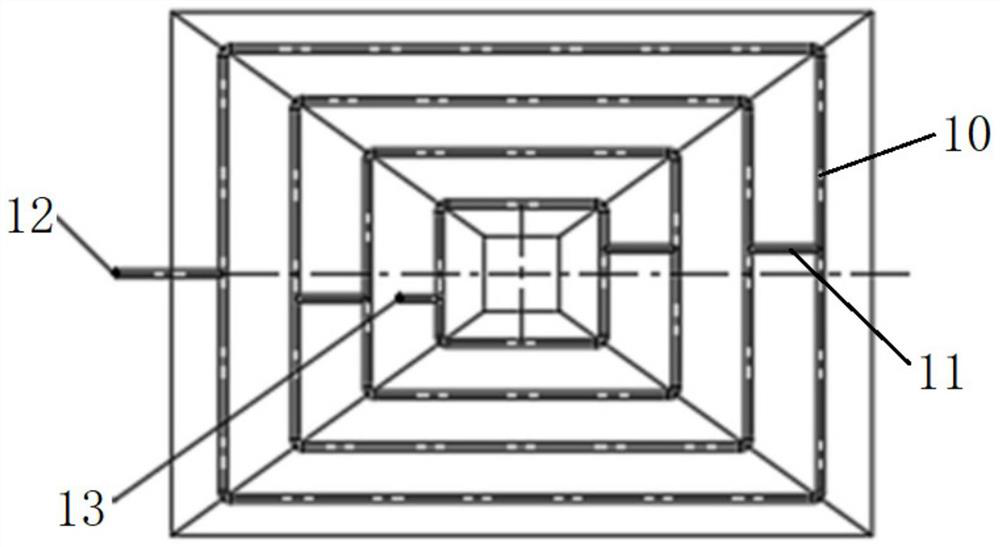

[0030] In a typical embodiment of the present invention, such as Figure 1-Figure 2 As shown, a fixed-bed process desulfurization tower that can be heated and dehumidified is proposed, including a desulfurization tower 8 and heating pipes arranged in layers at the unloading cone section 9 of the desulfurization tower.

[0031] The desulfurization tower 8 is a fixed-bed process desulfurization tower, the bottom of which is the discharge cone section 9, the discharge cone section is in the form of a cone with the tip pointing down as a whole, and the heating pipe is sleeved on the outer wall of the discharge cone section 9, and Layered settings.

[0032] Specifically, the heating pipeline includes multilayer air pipes 10, and each layer of air pipes 10 is arranged in a ring on the outer wall of the discharge cone section of the desulfurization tower, and the multilayer air pipes are arranged at different heights of the outer wall of the discharge cone section. The size of the mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com