Electric control adsorption membrane assembly and use method thereof

An adsorption membrane and electronic control technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as unfavorable cleaning and complex overall structure, so as to promote development, be suitable for popularization and application, and the process is simple and economical The effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

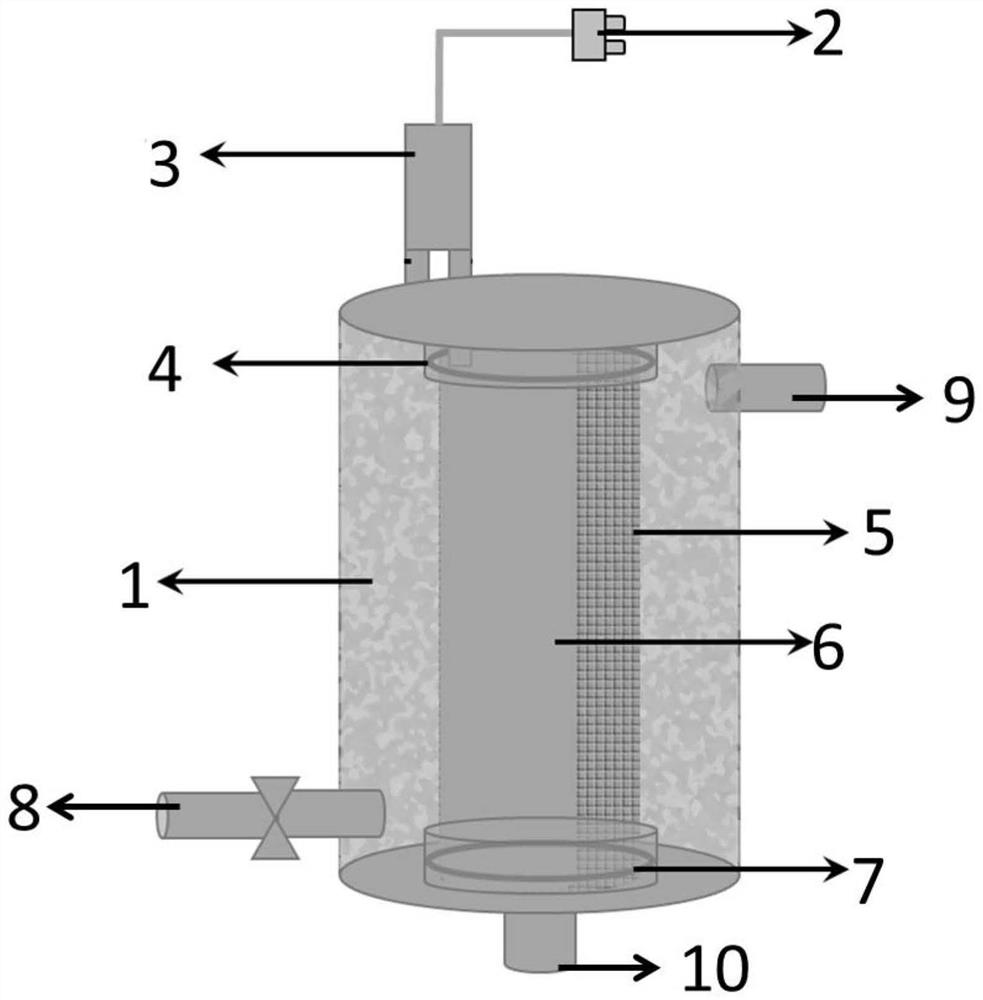

[0063] This embodiment provides a figure 1 In the electronically controlled adsorption membrane assembly shown, the electrically controlled adsorption membrane assembly includes an outer casing 1; a conductive layer is provided on the inner wall of the outer casing 1;

[0064] The side wall of the outer shell 1 is provided with a water inlet 8 and a return port 9; the bottom of the outer shell 1 is provided with a purified water outlet 10; the top of the outer shell 1 is provided with a power supply unit;

[0065] The outer casing 1 is provided with an electronically controlled adsorption membrane assembly; the electrically controlled adsorption membrane assembly includes a fixing device and an electrically controlled adsorption device; the electrically controlled adsorption device includes an electrically controlled adsorption membrane 6 and a hollow support net 5; The electronically controlled adsorption film 6 is connected to the power supply unit through the electronically...

Embodiment 2

[0073] This embodiment provides an electronically controlled adsorption membrane module. The difference between the electronically controlled adsorption membrane module and the embodiment is only that the distance between the conductive layer and the electrically controlled adsorption membrane in the electronically controlled adsorption membrane module provided by this embodiment is 0.3 cm.

Embodiment 3

[0075] This embodiment provides an electronically controlled adsorption membrane module. The difference between the electronically controlled adsorption membrane module and the embodiment is only that the distance between the conductive layer and the electrically controlled adsorption membrane in the electronically controlled adsorption membrane module provided by this embodiment is 3 cm. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com