Method for preparing molecular sieve membrane by dip-coating molecular sieve seed crystal method

A technology of molecular sieve and seed crystal method, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., to achieve the effects of avoiding uneven performance, reducing operation difficulty, and avoiding different performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

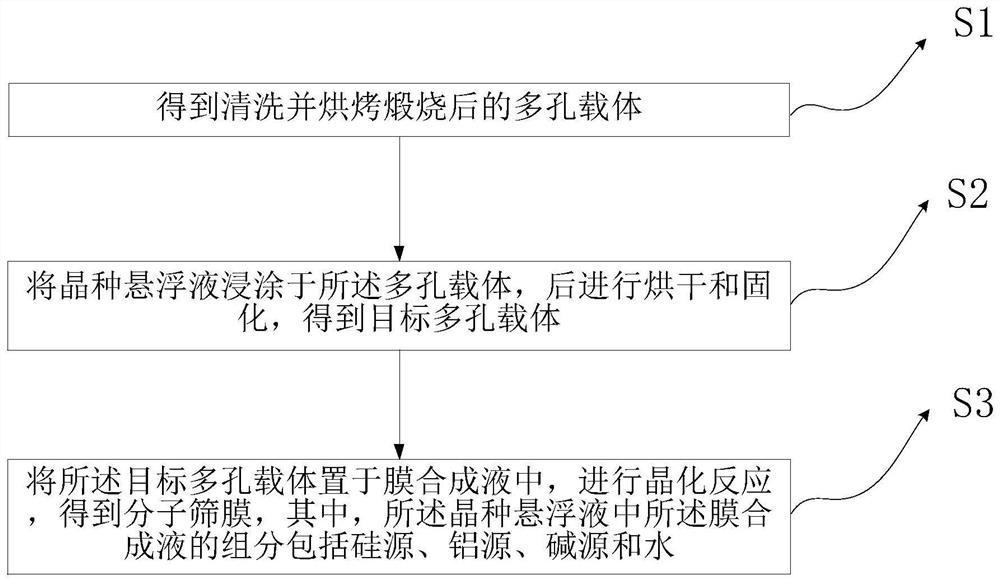

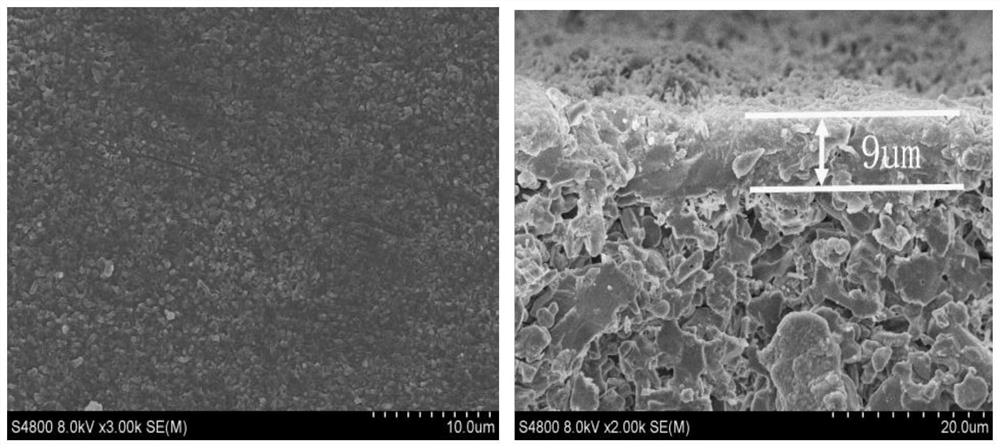

[0076] This embodiment provides a method for preparing molecular sieve membranes by dip-coating molecular sieve seed crystals, such as figure 1 As shown, the method includes the following steps: S10. Obtain the porous carrier after cleaning and baking;

[0077] S20. Dip-coat the seed crystal suspension on the porous carrier, and then dry and solidify to obtain the target porous carrier; specifically include: S1. Seal both ends of the porous carrier and place the seed crystal suspension In the solution, dip coating for 20-180s, and then release the seed crystal suspension immersed in the porous carrier, and dip the porous carrier after dipping; S2. Dry the porous carrier after dipping, and then solidify it to obtain Porous carrier after solidification; S3. Steps S1-S2 are repeated several times to obtain the target porous carrier.

[0078] S30. Place the target porous carrier in the membrane synthesis solution, and carry out crystallization reaction to obtain a molecular sieve...

Embodiment 2

[0087] The embodiment of the present application provides a method for preparing a molecular sieve membrane by dip-coating a molecular sieve seed crystal method, the method comprising the following steps: S11. Obtaining a porous carrier after cleaning, baking and calcining;

[0088] S12. Dip-coat the seed crystal suspension on the porous carrier, and then dry and solidify to obtain the target porous carrier; specifically include: S121. Seal both ends of the porous carrier and place the seed crystal suspension In the solution, dip coating for 20-180s, and then release the seed crystal suspension immersed in the porous carrier, and dip the porous carrier after dipping; S122. Dry the porous carrier after dipping, and then solidify it to obtain Porous carrier after solidification; S123. Steps S121-S122 are repeated multiple times to obtain the target porous carrier.

[0089] S13. Place the target porous carrier in the membrane synthesis solution, and carry out crystallization reac...

Embodiment 3

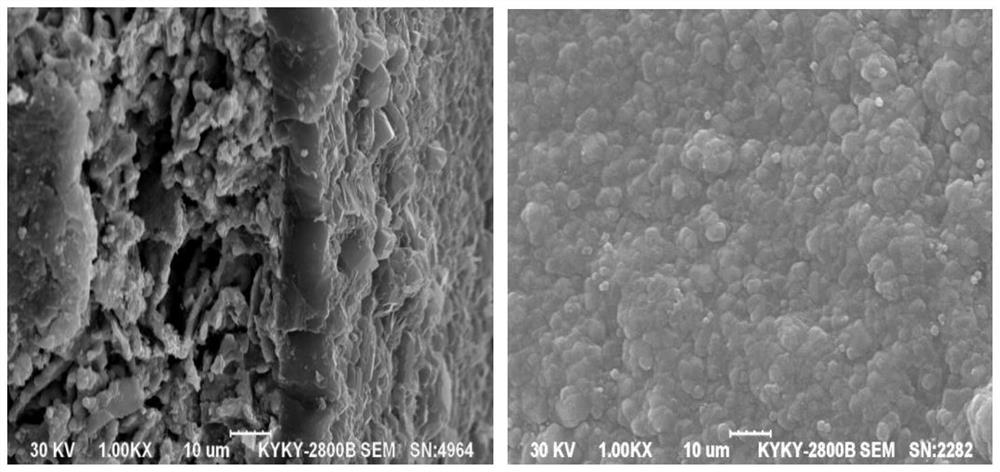

[0100] The difference between this embodiment and embodiment 2 is:

[0101] (2) Dip-coating seed crystals at room temperature: Take 0.5 g of industrial ZSM-5 molecular sieve seed crystals (purchased from Tianjin University of Technology) with an average particle size of 0.2 μm and a molar ratio of silicon to aluminum of 25, dissolve them in 500 mL of deionized water, and sonicate for 40 minutes Prepare the seed crystal suspension; seal the calcined and cooled carrier tube with a polytetrafluoroethylene plug, immerse in the seed crystal suspension for 150s, remove the polytetrafluoroethylene plug at the mouth of the carrier tube, release the water immersed in the carrier tube, and immediately Bake at 80°C for 3 hours, then turn to 200°C overnight, and calcine and solidify;

[0102] (4) According to the formula Na 2 O:SiO 2 :Al 2 o 3 :H 2 O:NaF=0.21:1:0.039:51.63:1 is mixed with ZSM-5 molecular sieve membrane synthesis liquid;

[0103] (5) Seal the carrier tube introduced ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com