Manufacturing process and device of agricultural wheel

A manufacturing process and manufacturing device technology, applied in the field of agricultural wheel manufacturing process and devices, can solve the problems of inaccurate positioning, increase materials, scrap rate, etc., and achieve the effect of precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

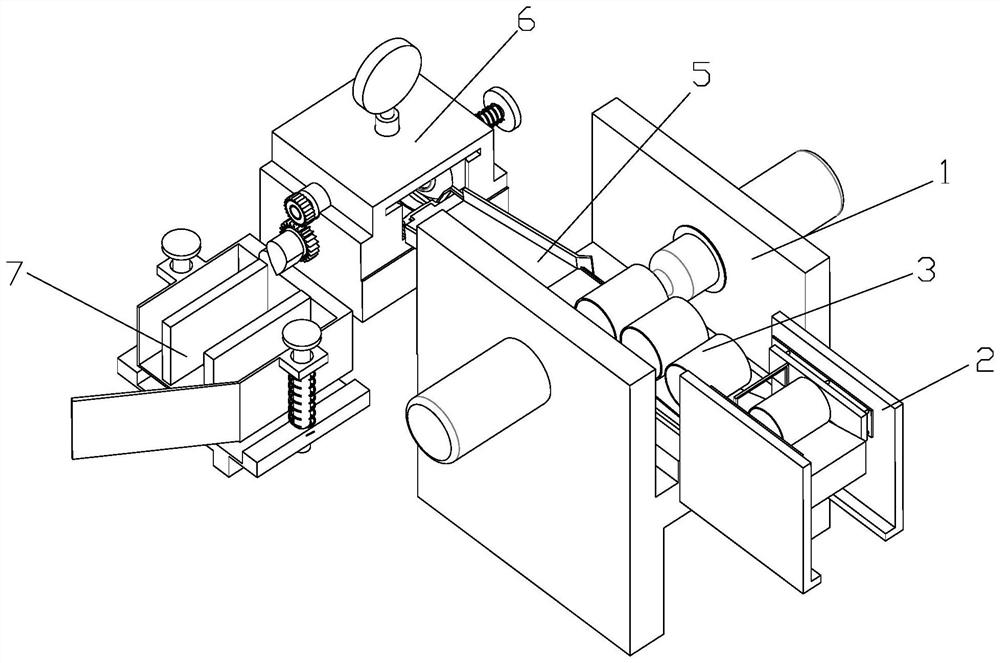

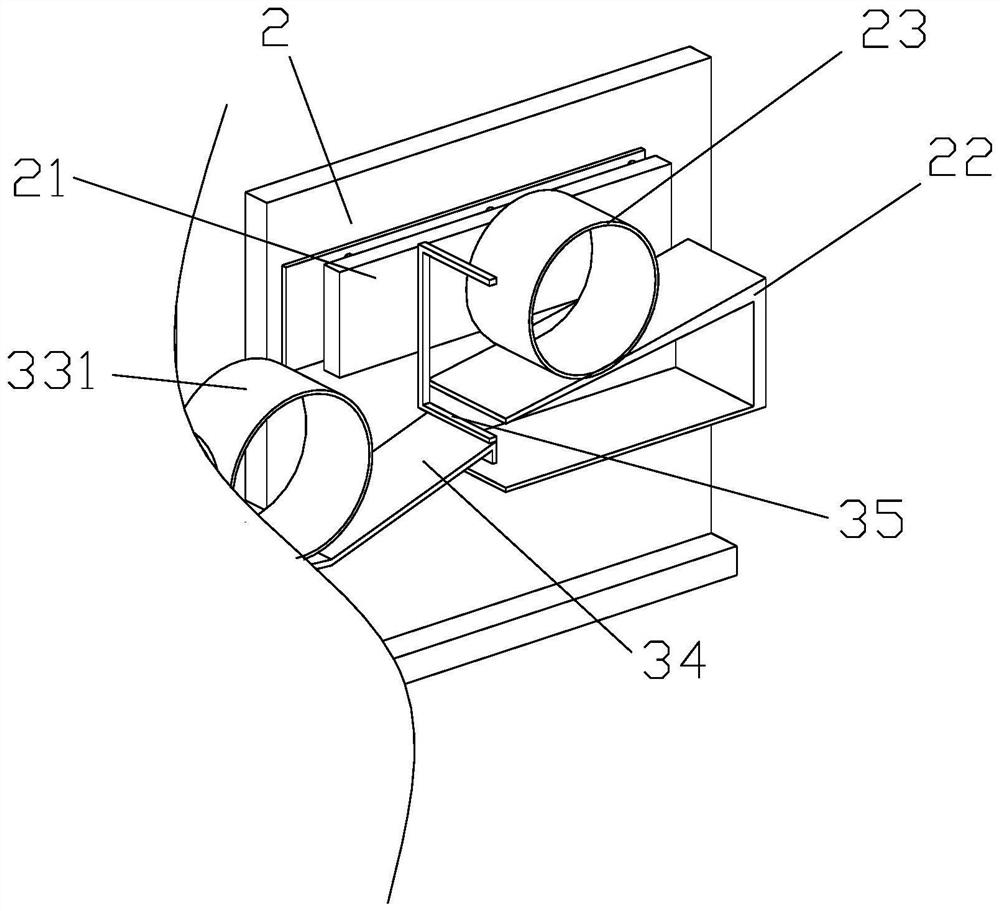

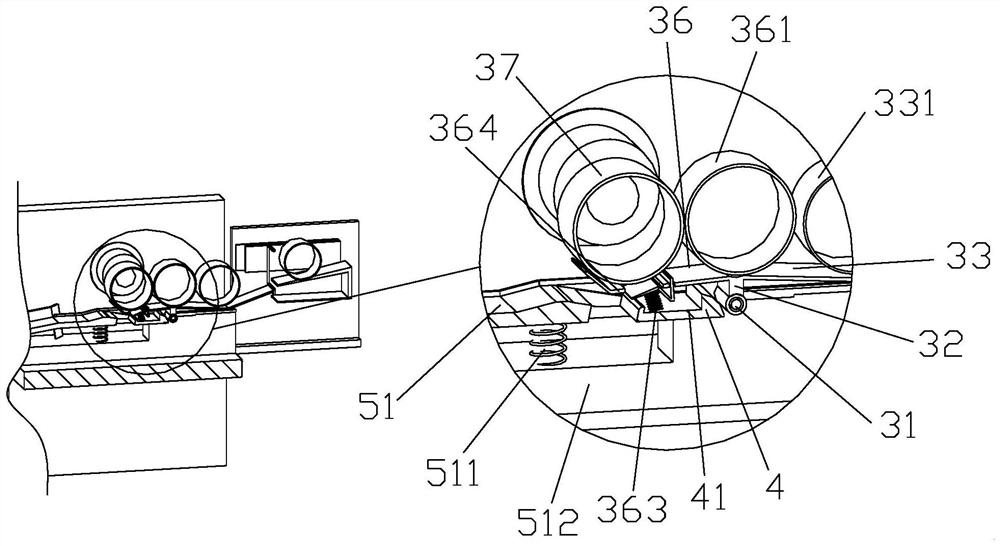

[0037] Attached below Figure 1-7 The present invention is further described with embodiment:

[0038] A kind of manufacturing process of agricultural wheel, concrete manufacturing process steps are as follows:

[0039] S1. Casting molding: spin casting is used to reprocess the cast blank rim, mainly to carry out rotary stamping on the wheel frame part. During this process, the wheel frame part is heated and the rotary knife is rotated to make the wheel frame Gradually elongated and thinned, extruded from 15mm to 7mm, the metal molecules inside the wheel frame will be arranged more closely, the metal strength will be higher, and the weight will also be reduced;

[0040] S2. Heat treatment: Carry out heat treatment on the wheel through heat treatment equipment, and obtain the expected structure and performance by means of heating, heat preservation and cooling. Different strength and toughness requirements also require different heat treatment temperatures to control;

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com