A foot clipper for computer motherboard processing based on artificial intelligence

A computer motherboard and artificial intelligence technology, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of different lengths of reserved pins, high labor intensity of workers, low work efficiency, etc., to achieve neat length, The effect of reducing labor intensity and improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

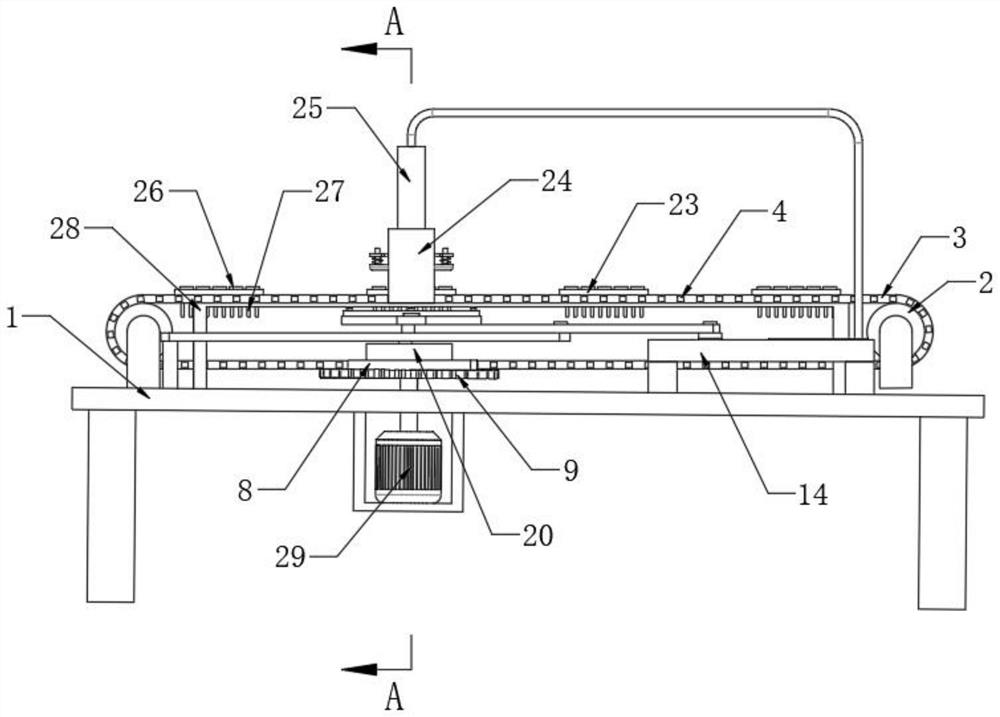

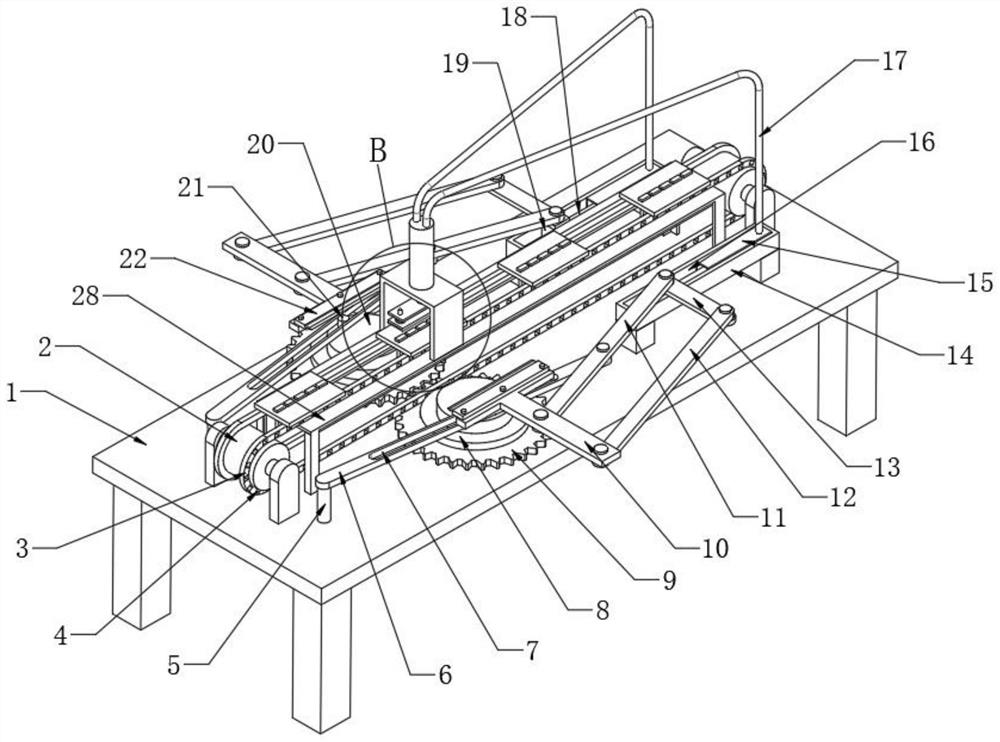

[0028] In the first embodiment, the main board 23 to be cut is placed on the two transmission belts 3 at intervals, and the pins are placed downward. figure 1 As shown in the figure, the two transmission belts 3 are intermittently driven by the drive assembly, and the main board 23 on it is driven to feed together. When the main board 23 moves to the shearing knife 22, the transmission belt 3 stops driving, and is driven by the external structure. The two mounting plates 10 are moved relative to each other, and the pins are cut by two shearing knives 22, and then the two mounting plates 10 are moved opposite to each other.

[0029] Then the drive assembly drives the two transmission belts 3 for transmission, and moves the next main board 23 to the shearing knife 22, so that when the two transmission belts 3 are driven, the two mounting plates 10 move opposite to each other, and when the two transmission belts 3 stop, The two mounting plates 10 are moved relative to each other ...

Embodiment 2

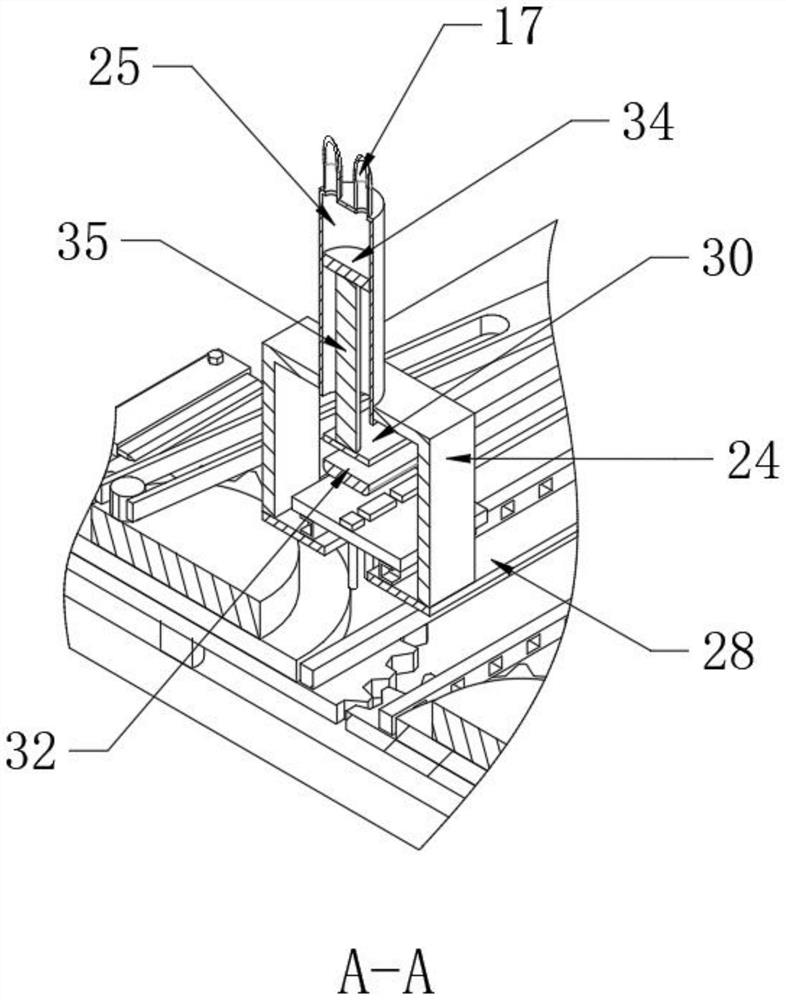

[0049] Example two, as Figure 7 As shown, the difference from the first embodiment is that there is one support frame 28, which is located between the two transmission belts 3, and is located below the slender frame 24. When the transmission belt 3 drives the main board 23 to move above the support frame 28, the support The frame 28 will support the main board 23, and in this way, the pins of the double rows can be cut. When the main board 23 is moved to the top of the support frame 28, the two rows of pins will be located on both sides of the support frame 28, respectively. The support frame 28 is attached so that the two shearing knives 22 and the support frame 28 can cut the pins together, which is more efficient than cutting a row of pins on the main board 23 in the first embodiment.

[0050] Working principle: When the artificial intelligence-based computer motherboard processing is used with a foot cutting machine, the main board 23 to be cut is placed on the two transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com