Comprehensive grinding equipment for automobile belt pulley machining

A pulley and comprehensive technology, applied in metal processing equipment, grinding/polishing equipment, grinding machines, etc., to achieve smooth and stable movement, reduce labor intensity and hidden dangers, and improve grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

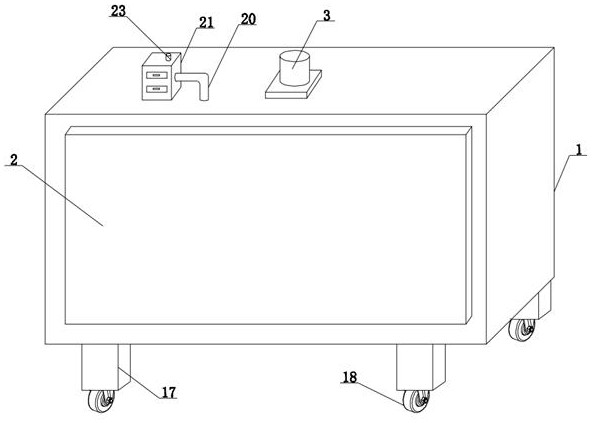

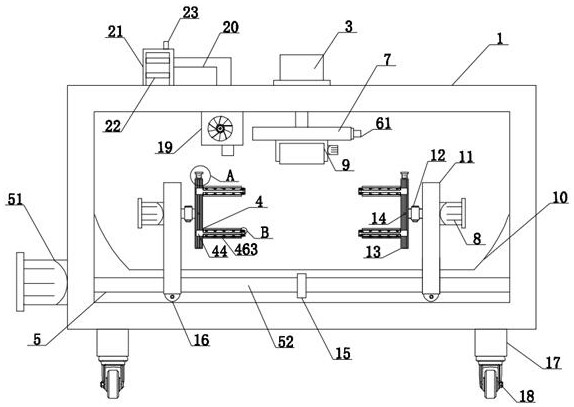

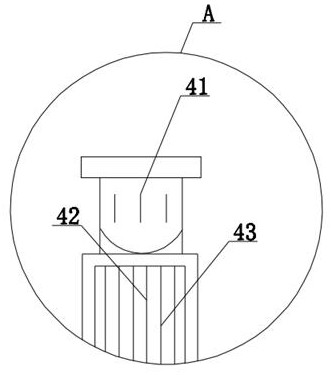

[0038] see figure 1 , a kind of comprehensive grinding equipment for automobile pulley processing, comprising a grinding box 1, a first cylinder 3 is fixedly connected to the middle part of the upper end of the grinding box 1, a bearing seat 7 is fixedly connected to the output end of the first cylinder 3, and one side of the bearing base 7 A second adjustment assembly 6 is provided, and the lower side of the bearing seat 7 is slidably connected with a grinding wheel body 9 through the second adjustment assembly 6. The grinding wheel body 9 is composed of a motor and a grinding wheel. The left side of the upper end of the grinding box 1 is fixedly connected with a collector Box 21, the inside of collection box 21 is provided with multiple groups of filter screens 22, the upper end side of polishing box 1 is fixedly connected with outlet pipe 23, and the right side side of polishing box 1 is fixedly connected with dust discharge pipe 20, and the side of dust discharge pipe 20 O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com