Dual-motor gearbox and engineering machinery

A technology for construction machinery and gearboxes, which is applied in the direction of mechanical equipment, gear transmissions, belts/chains/gears, etc. It can solve the problems of unfavorable overall machine layout and maintenance, large space occupation, and scattered structures, and achieves compact structure and low occupation. The effect of small space and low number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

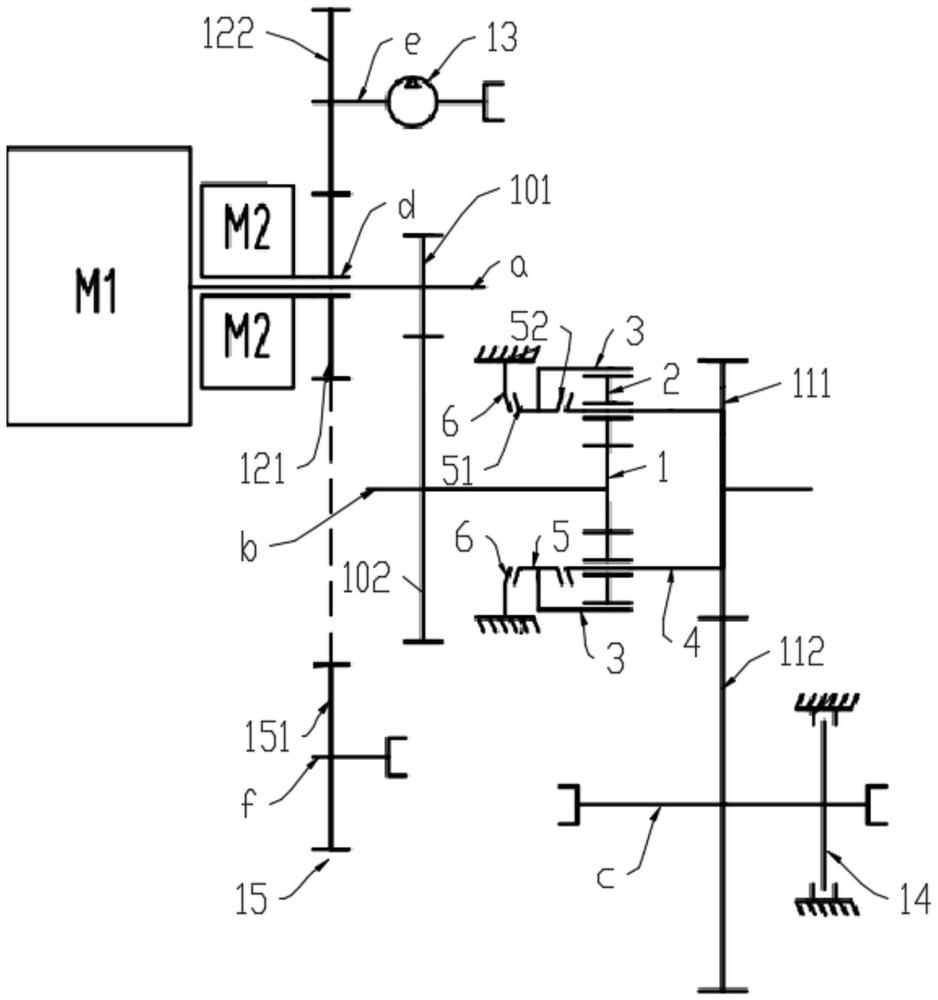

[0035] A dual-motor gearbox includes a first output shaft c, a second output shaft e, a first motor M1 and a second motor M2. Wherein, the first motor M1 includes a first input shaft a, the first input shaft a is connected with the first output shaft c through a first transmission mechanism, and is used to drive the first output shaft c to rotate; the second motor M2 includes a second input shaft d, the second input shaft d is connected with the second output shaft e through the second transmission mechanism, and is used to drive the second output shaft e to rotate; the second input shaft d is a hollow shaft, and the second input shaft d is movably sleeved on the first input shaft on axis a.

[0036] Utilizing the technical solution of the present invention, the second input shaft d of the second motor M2 is set as a hollow shaft, which is movably fitted on the first input shaft a of the first motor M1, and the two motors are integrated into one, compact in structure, small in...

Embodiment 2

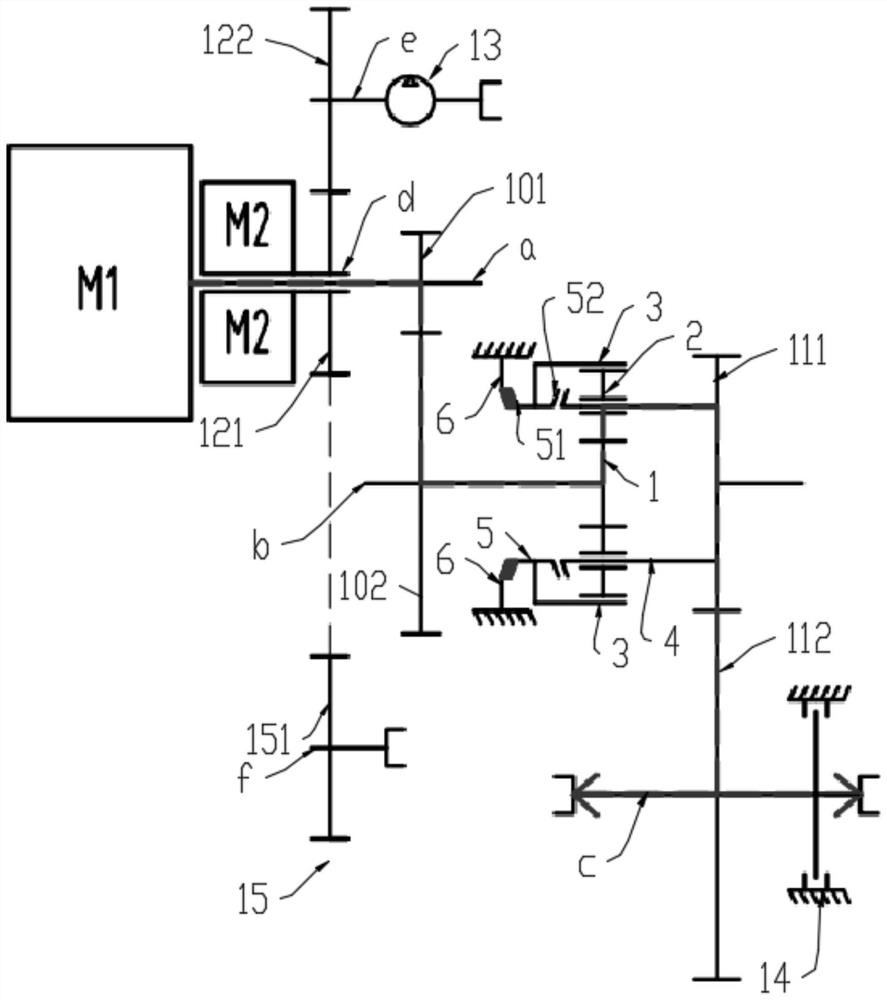

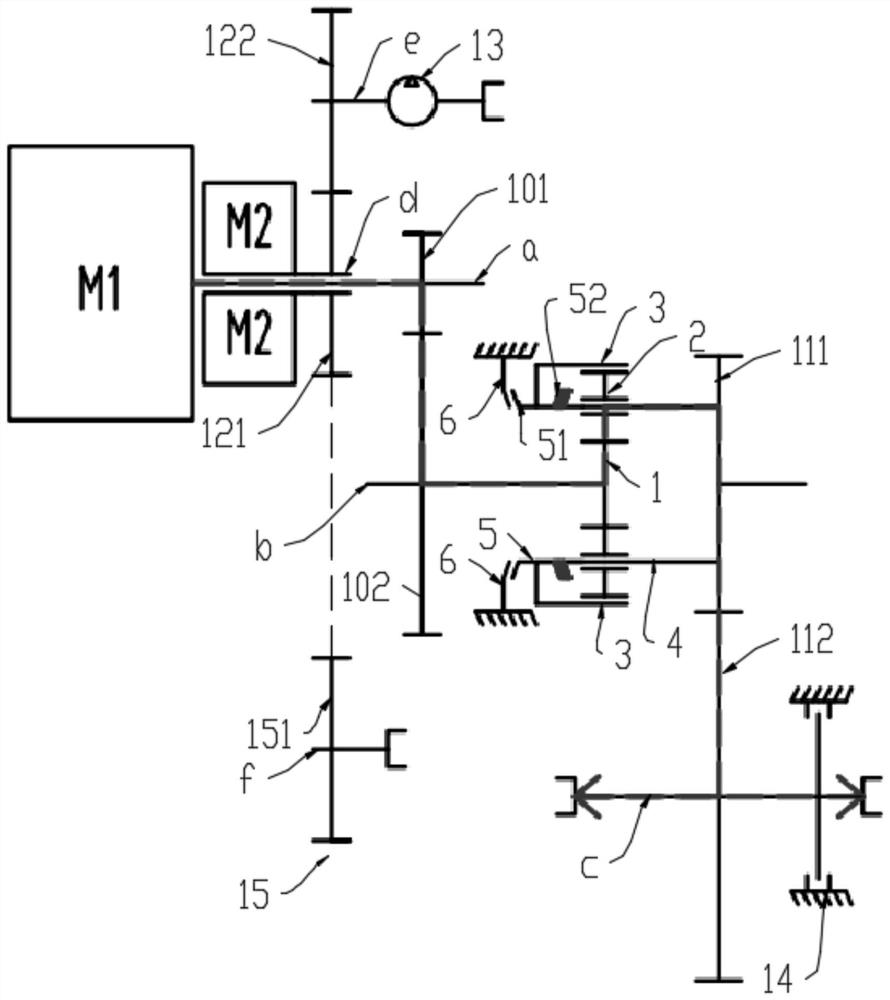

[0055] The difference between this embodiment and embodiment 1 is that the shift mechanism includes a first clutch 8 and a second clutch 9, refer to Figure 4 , one end of the first clutch 8 is fixed, and the other end is connected with the first ring gear 3; one end of the second clutch 9 is connected with the planet carrier 4, and the other end is connected with the sun gear 1. In this embodiment, the second clutch 9 is connected with the sun gear 1 through the intermediate shaft b, Figure 4 in neutral state.

[0056] refer to Figure 5 , wherein the first clutch 8 is in the engaged state, and the second clutch 9 is in the disengaged state. At this time, the first ring gear 3 is locked, and the sun gear 1 drives the planetary gear 2 to rotate, thereby driving the planetary gear carrier 4 to rotate. At this time, the output speed is the first gear speed, and the order of power transmission is: first input shaft a, first driving wheel 101, first driven wheel 102, intermedi...

Embodiment 3

[0060] A construction machine includes the dual-motor gearbox described in any one of the above embodiments.

[0061] Specifically, the construction machine is a loader. Wherein, the first motor M1 is a traveling motor, which drives the loader to travel in two gears and two speeds or reverse in one gear. The second motor M2 is an operating motor, which drives the steering, lifting and lubrication of the loader.

[0062] According to the above description, the patent application has the following advantages:

[0063] 1. The dual motors are integrated into one body, the structure is compact, and the space occupied is small, which is conducive to the layout and maintenance of the whole vehicle.

[0064] 2. The transmission structure of a single planetary row is adopted, and a synchronizer is used to realize the switching of two gears, with a small number of parts and a simple structure;

[0065] 3. The number of gear pairs for transmission between the first input shaft a and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com