Mask pattern optimization design method for manufacturing curved surface embossment contour device

A contour and relief technology, applied in computer-aided design, instrumentation, calculation, etc., can solve problems that are difficult to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

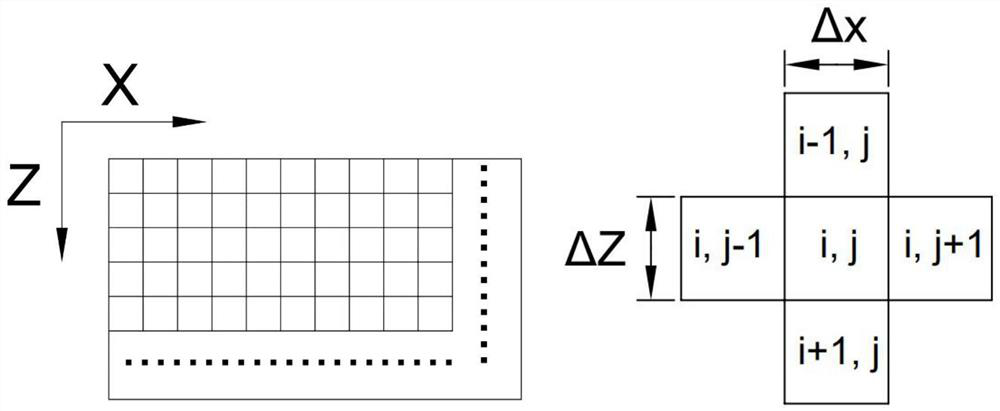

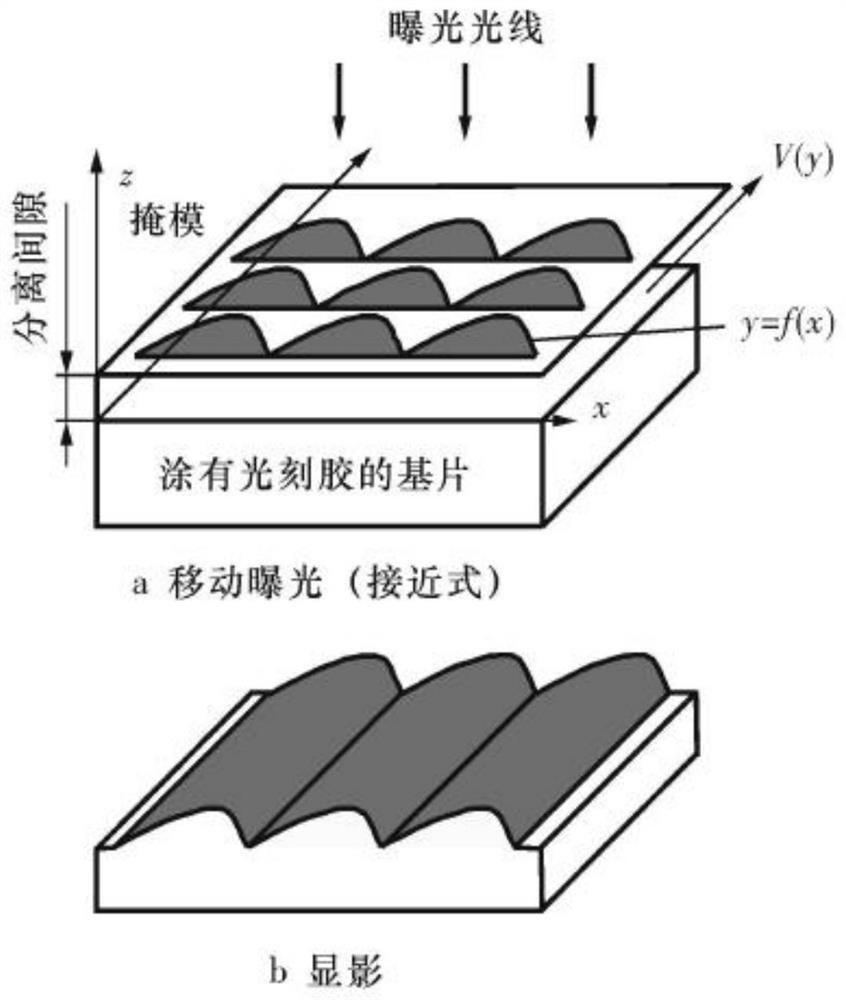

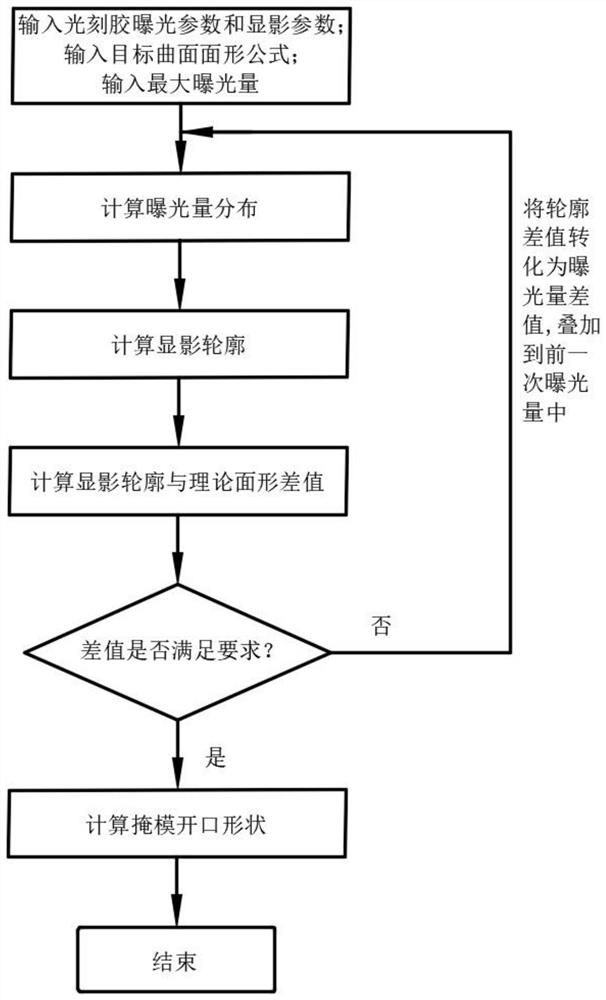

[0022] The present invention is based on the photoresist exposure model, the development model and the computer simulation method of the development profile to establish the relationship between the exposure amount and the development profile, and then use the iterative optimization algorithm to optimize the design to obtain the exposure amount distribution, and calculate the mask opening shape according to the mask moving exposure principle distributed.

[0023] The present invention relates to a method for optimizing the design of a mask plate pattern for making curved surface relief profile devices. Using the method to optimize the design of the mask comprises the following steps:

[0024] Step (1), establish a photoresist exposure model, and describe the light intensity distribution and photosensitivity of each point inside the photoresist ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com