Production method of broiler feed

A production method and broiler feed technology, which are applied in the direction of animal feed, animal feed, molding or processing of animal feed, etc., to achieve the effect of improving conditioning effect, practical and convenient, and comprehensive nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

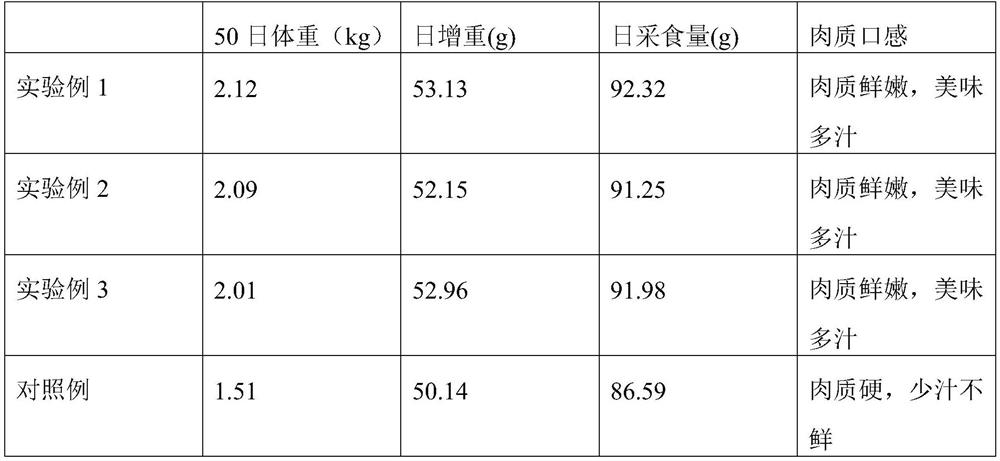

Examples

experiment example 1

[0053] Experimental Example 1, this embodiment provides a broiler feed production method, comprising:

[0054] 1) Select 20 parts of corn flour, 10 parts of soybean meal powder, 10 parts of bran, 2 parts of eggshell powder and 2 parts of rice bran in parts by weight;

[0055] 2) Put the selected corn flour, soybean meal powder, bran, eggshell powder and rice bran into a feed maturation and fermentation device for maturation, the steam temperature for maturation is 150°C, and the stirring time is 8 minutes. The maturation and fermentation device includes:

[0056] box;

[0057] A stirring device, which includes a stirring shaft and a stirring rod, one end of the stirring shaft is connected to the output shaft of the motor fixed on the upper end of the casing, and a plurality of parallel stirring rods are arranged on the stirring shaft;

[0058] A steam pipe, which is evenly arranged on the inner wall of the box, and an air nozzle is evenly arranged on the steam pipe, and a scr...

experiment example 2

[0075] Experimental Example 2, this embodiment provides a broiler feed production method, comprising:

[0076] 1) Select 30 parts of corn flour, 20 parts of soybean meal powder, 15 parts of bran, 4 parts of eggshell powder and 5 parts of rice bran in parts by weight;

[0077] 2) Put the selected corn flour, soybean meal powder, bran, eggshell powder and rice bran into a feed maturation and fermentation device for maturation, the steam temperature for maturation is 180°C, and the stirring time is 10 min. The maturation and fermentation device includes:

[0078] box;

[0079] A stirring device, which includes a stirring shaft and a stirring rod, one end of the stirring shaft is connected to the output shaft of the motor fixed on the upper end of the casing, and a plurality of parallel stirring rods are arranged on the stirring shaft;

[0080] A steam pipe, which is evenly arranged on the inner wall of the box, and an air nozzle is evenly arranged on the steam pipe, and a screen...

experiment example 3

[0097] Experimental Example 3, this embodiment provides a broiler feed production method, comprising:

[0098] 1) Select corn flour 25, soybean meal flour 15, bran 12, eggshell powder 3 and rice bran 3 in parts by weight;

[0099] 2) Put the selected corn flour, soybean meal powder, bran, eggshell powder and rice bran into a feed maturation and fermentation device for maturation, the steam temperature for maturation is 160°C and the mixing time is 9 minutes. The maturation and fermentation device includes:

[0100] box;

[0101] A stirring device, which includes a stirring shaft and a stirring rod, one end of the stirring shaft is connected to the output shaft of the motor fixed on the upper end of the casing, and a plurality of parallel stirring rods are arranged on the stirring shaft;

[0102] A steam pipe, which is evenly arranged on the inner wall of the box, and an air nozzle is evenly arranged on the steam pipe, and a screen is arranged on the air nozzle;

[0103] a ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com