Low-temperature filter pressing and drying method and device for filter press

A technology of drying device and filter press, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of unfavorable back-end disposal of de-cemented cake, inability to reduce moisture content, poor dehydration performance, etc., and achieve improvement. Poor fluidity, avoiding the escape of odor, reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

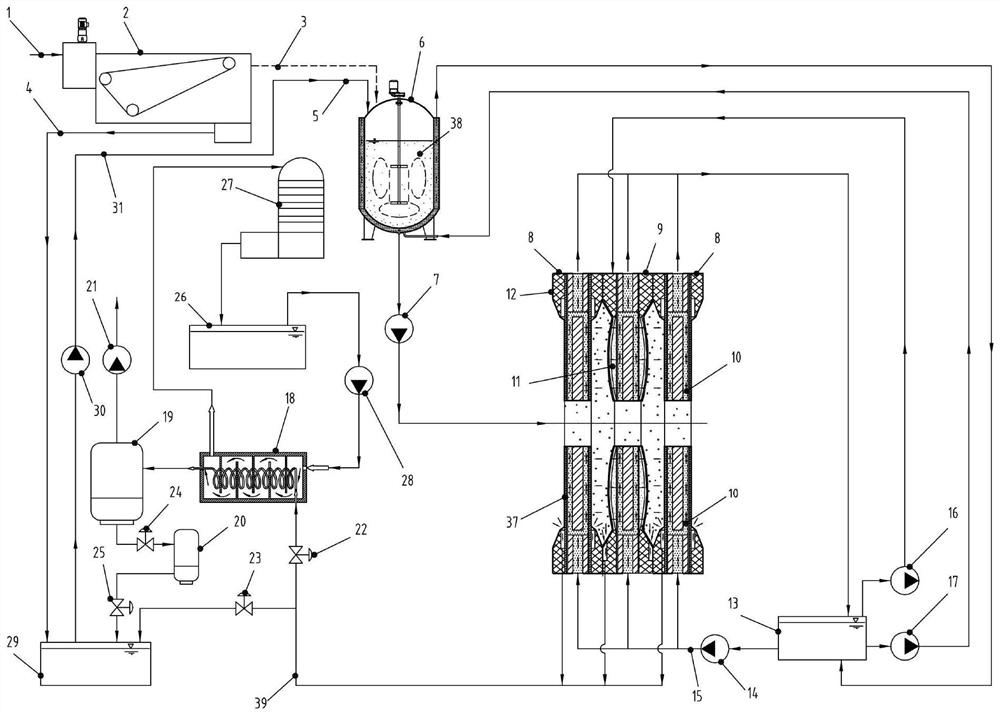

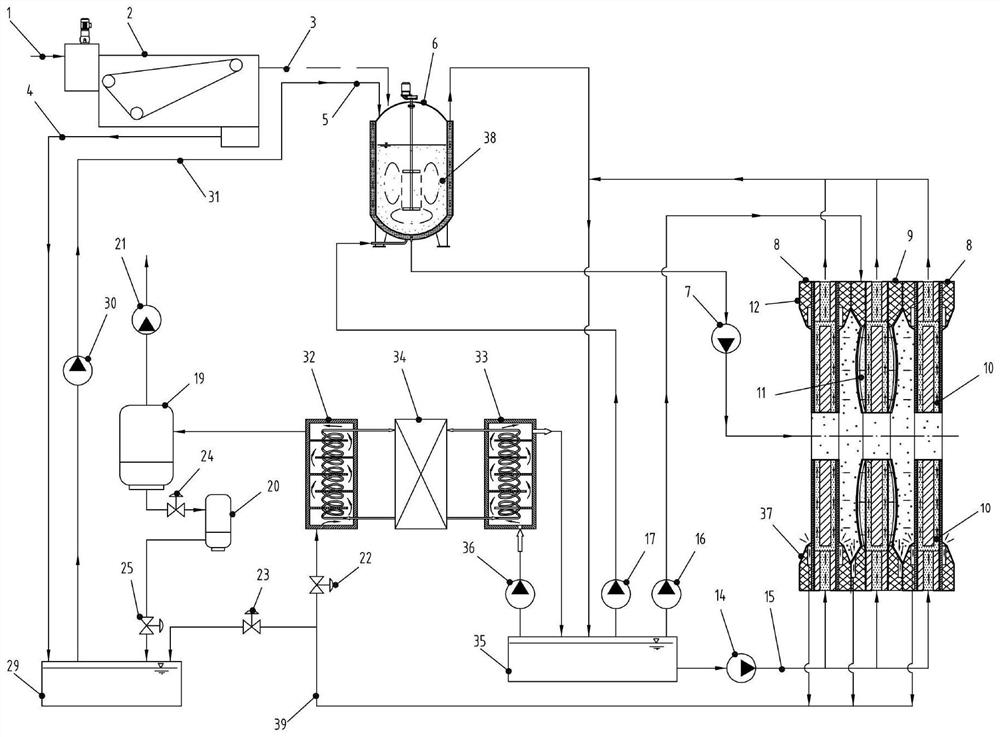

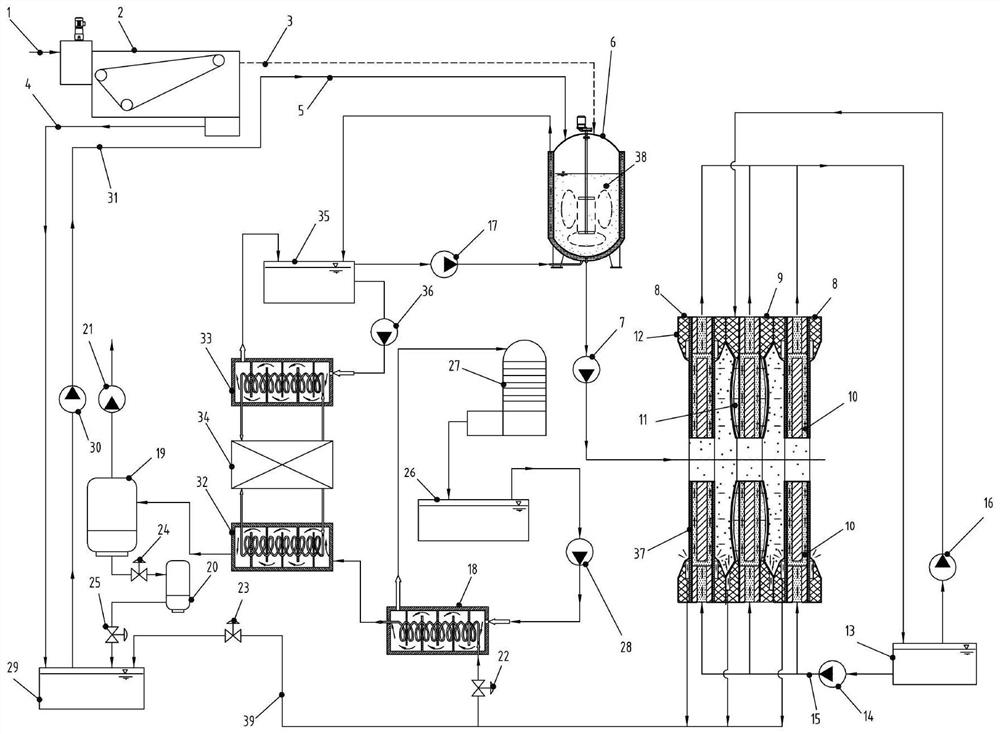

[0045] like figure 1 The shown low-temperature filter press drying device of the present invention for filter press consists of a sludge thickening device 2, a conditioning tank 6, a heating filter press 37, a heating unit 13, and a vacuum generating unit including a gas-liquid separation tank 19, a condensate tank 20 and vacuum pump 21 and vapor condensing unit comprise condenser 18, cooling water tank 26 and cooling cooling tower 27 and form.

[0046] When it is assembled, the heating filter press 37 is used as the main body, and the conditioning tank 6 is placed between the heating filter press 37 and the sludge thickening device 2, and the conditioning tank 6 is connected to the heating unit 13 by a pipeline. Warm pump 17, conditioning tank 6 connect pipeline to heating filter press 37, sludge pressurization pump 7 is set on the pipeline, sludge thickening device 2 connects pipeline to guide filtrate 4 to filtrate tank 29, sludge thickening device 2 The produced thickened...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com