High-precision rotating shaft surface machining equipment

A surface processing, high-precision technology, applied in conveyor objects, transportation and packaging, loading/unloading, etc., can solve the problems of high manufacturing cost and can only wait at the loading position, etc., to reduce manufacturing costs and improve productivity. Material efficiency, the effect of eliminating the need for control devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

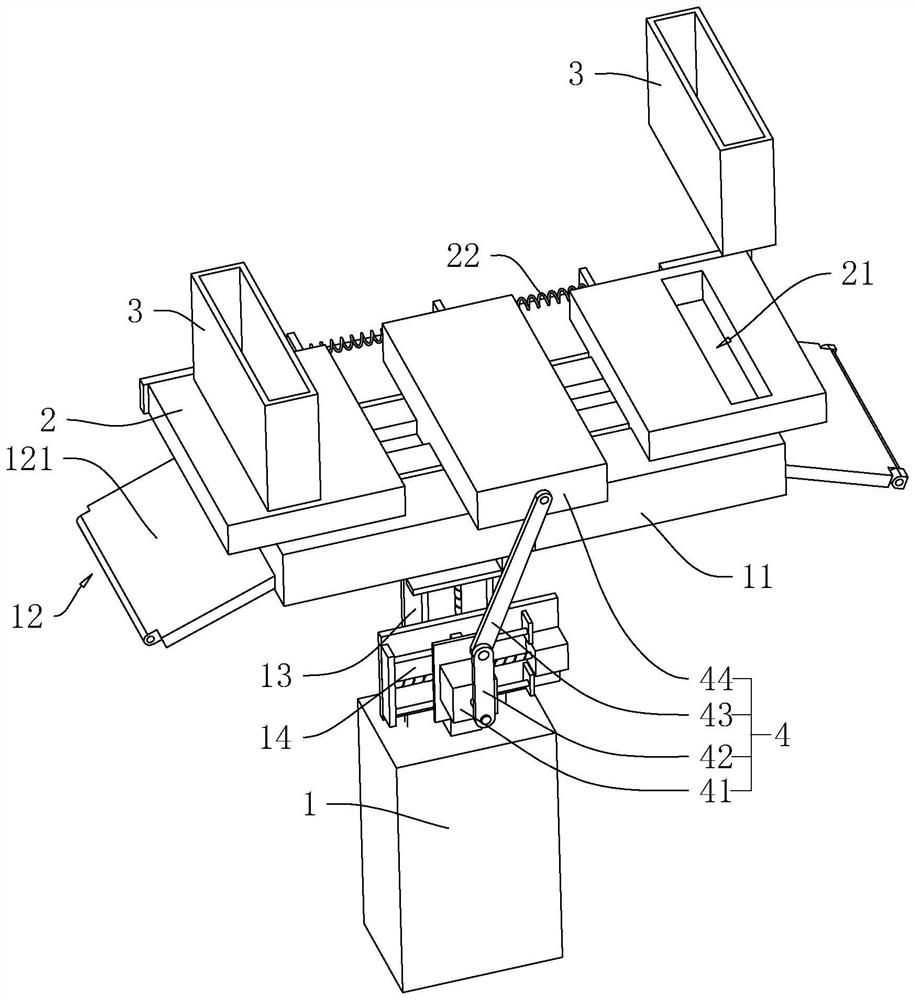

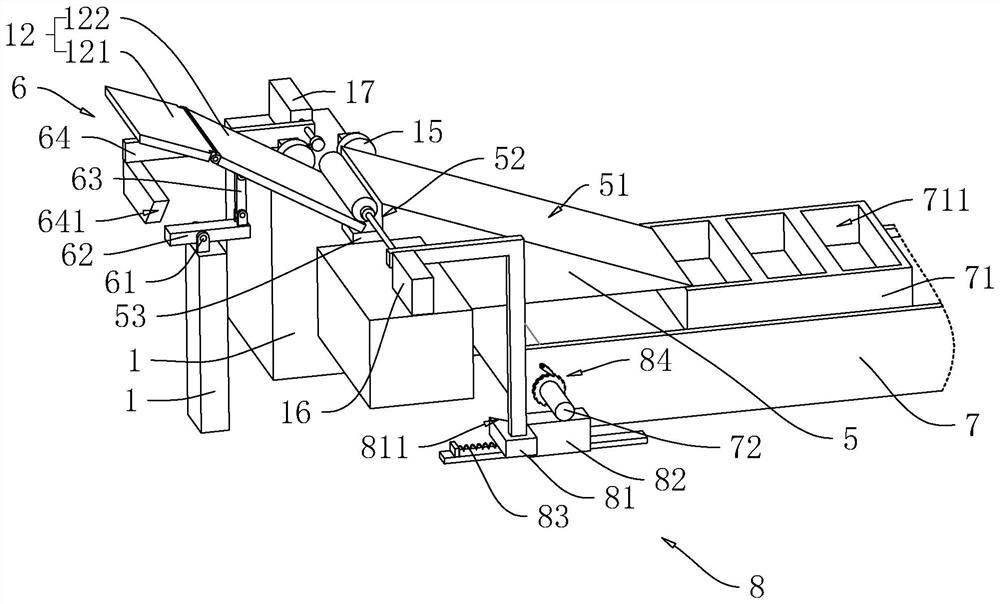

[0046] Contraction below Figure 1-2 Further detailed description of the present application.

[0047] The present application example discloses a high-precision spindle surface processing equipment. Refer figure 1 and figure 2 The high-precision spindle surface processing equipment includes a rack 1, a shipping slider 2, a storage tube 3, and a crank link mechanism 4, in particular, the frame 1 includes a slip platform 11 and a plate 12, slip platform 11 level The upper surface of the slip platform 11 is also a horizontal plane; two of the precipient plates 12 are provided, and the two of the two generator plates 12 are disposed adjacent to both ends opposite to the slip platform 11, wherein the discharge plate 12 is inclined, and the reference The tilt high of the plate 12 is in contact with the slip platform 11, and the inclined height of the discharge plate 12 is lower than the upper surface of the slip platform 11, and the inclinement of the discharge plate 12 extends in a dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com