On-load rope arranging device

A rope-arranging and load-carrying technology, which is applied in hoisting devices, engine components, engine lubrication, etc., can solve problems such as safety hazards, messiness, and reduced service life of steel wire ropes, and achieve the effect of improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

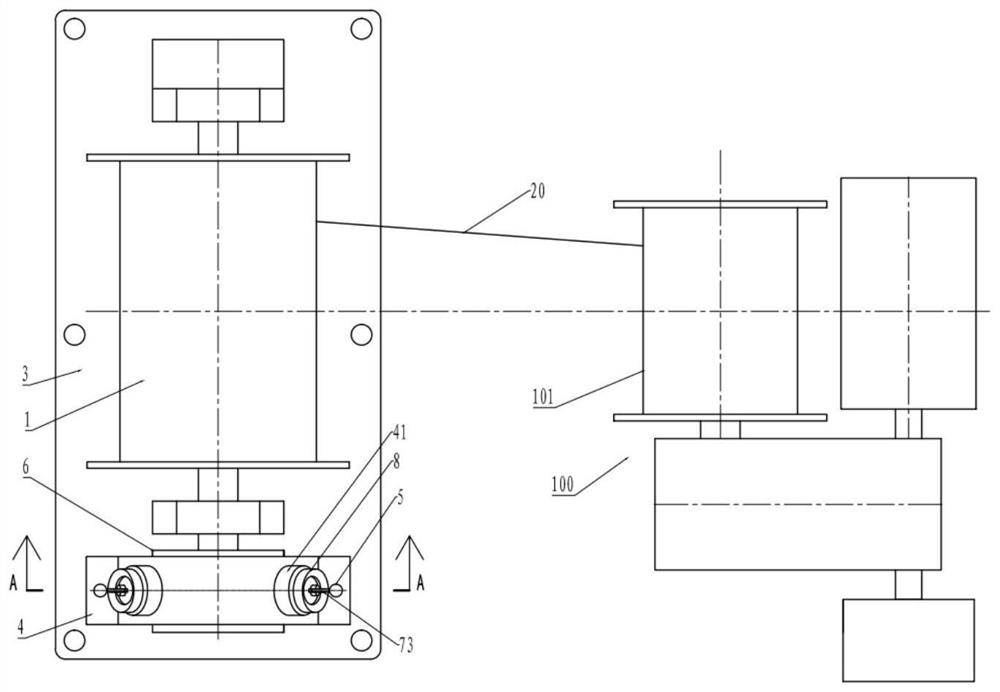

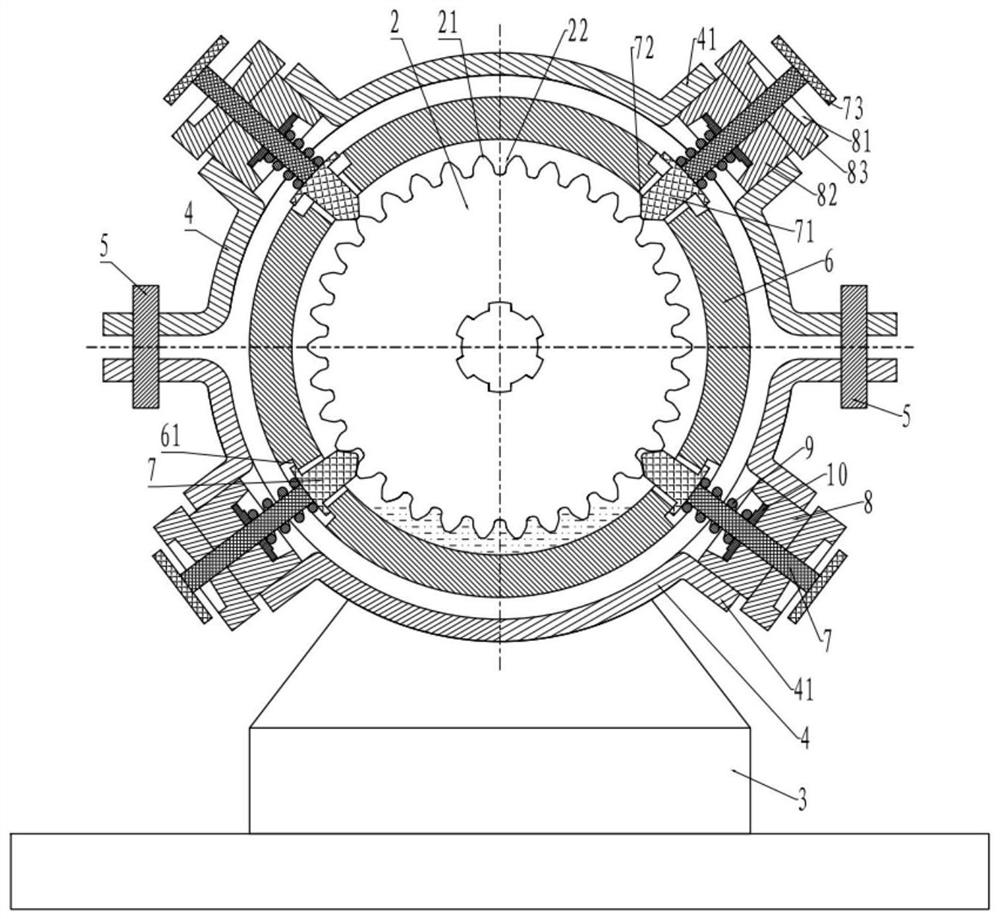

[0033] The embodiment is basically as attached figure 1 and figure 2As shown, a belt-loaded rope arrangement device includes a frame and a rope-accommodating reel 1 rotatably connected to the frame. The rope-accommodating reel 1 is coaxially fixedly connected with a turntable 2, and the turntable 2 is integrally formed in the circumferential direction. There are three protrusions 21, grooves 22 are formed between adjacent protrusions 21, and symmetrical guide surfaces are uniformly integrally formed on each protrusion 21.

[0034] The frame includes a support 3 and two oppositely arranged hoops 4. The rope-holding reel 1 is connected to the support 3 through the bearing seat, and the hoop 4 is semi-circular. The screw rod 5 is fixedly connected, and the double-ended screw rod 5 is rotatably connected to the support 3 (not shown in the figure), and the turntable 2 is located in the enclosed space of the two hoops 4; the support 3 is fixedly connected to the sleeve 6, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com