Modified carbon fiber high-strength composite material and preparation method thereof

A composite material and modified carbon technology, which is applied in the field of carbon fiber composite materials, can solve the problems of enhanced destructiveness, a large amount of production, and poor toughness, and achieves the effect of increasing strength and increasing impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

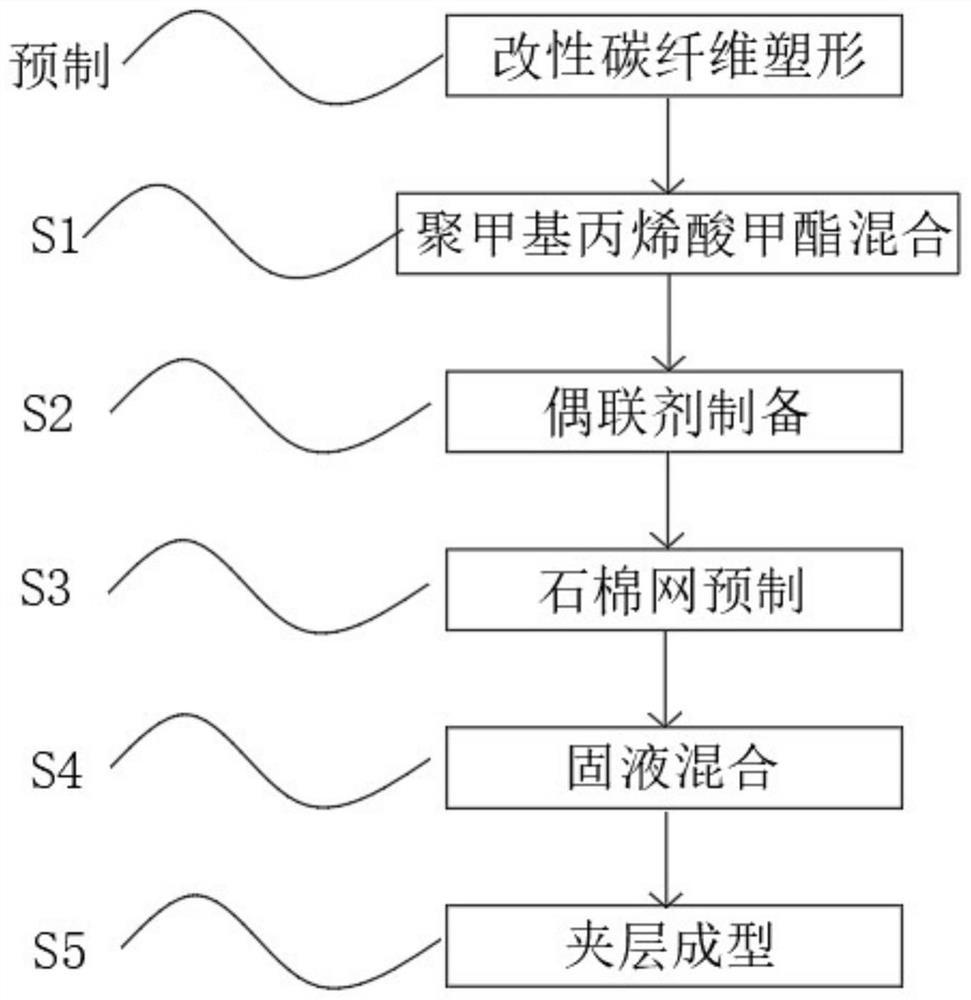

Method used

Image

Examples

Embodiment 1

[0022] A modified carbon fiber high-strength composite material, the raw material of the composite material is composed of the following materials in parts by weight: 15 parts of modified carbon fiber; 12 parts of TPU-polyurethane;

[0023] The manufacturing method of the modified carbon fiber is as follows: first, brush the outer surface of the mold of the workpiece with a layer of epoxy resin glue, and after curing, take out one-third of the prepared asbestos, spread it on the outer layer, It is coated with epoxy resin mixed with hardener, baked and cured under an infrared drying lamp, then placed in an oven to dry again, coated with epoxy resin again, attached with a carbon fiber film, and cured in an oven again. into modified carbon fiber, spare.

[0024] The temperature of the oven was set at 80° C. twice, and the drying time was controlled at 4 hours.

[0025] A third of the asbestos was made into separate roots and cut to 3 cm in length before being attached.

[0026]...

Embodiment 2

[0034] A modified carbon fiber high-strength composite material, the raw material of the composite material is composed of the following materials in parts by weight: 24 parts of modified carbon fiber; 15 parts of TPU-polyurethane;

[0035] The manufacturing method of the modified carbon fiber is as follows: first, brush the outer surface of the mold of the workpiece with a layer of epoxy resin glue, and after curing, take out one-third of the prepared asbestos, spread it on the outer layer, It is coated with epoxy resin mixed with hardener, baked and cured under an infrared drying lamp, then placed in an oven to dry again, coated with epoxy resin again, attached with a carbon fiber film, and cured in an oven again. into modified carbon fiber, spare.

[0036] The temperature of the oven was set at 100° C. twice, and the drying time was controlled at 5 hours.

[0037] One third of the asbestos was made into separate roots and cut to lengths of 5 cm before being attached.

[0...

Embodiment 3

[0046] A modified carbon fiber high-strength composite material, the raw material of the composite material is composed of the following materials in parts by weight: 20 parts of modified carbon fiber; 13 parts of TPU-polyurethane;

[0047] The manufacturing method of the modified carbon fiber is as follows: first, brush the outer surface of the mold of the workpiece with a layer of epoxy resin glue, and after curing, take out one-third of the prepared asbestos, spread it on the outer layer, It is coated with epoxy resin mixed with hardener, baked and cured under an infrared drying lamp, then placed in an oven to dry again, coated with epoxy resin again, attached with a carbon fiber film, and cured in an oven again. into modified carbon fiber, spare.

[0048] The temperature of the oven was set at 93° C. twice, and the drying time was controlled at 4 hours.

[0049] One third of the asbestos was made into separate roots and cut to lengths of 4 cm before being attached.

[0050...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com