Flexible customized digital blanket processing equipment and processing method

A kind of processing equipment and flexible technology, which is applied in flexible customized digital blanket processing equipment and processing field, can solve problems such as uneven brightness of cloth surface, adjustment of cloth surface tension, fiber cannot be scalded, etc., to prevent too close contact , improve practicality, improve the effect of hot light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

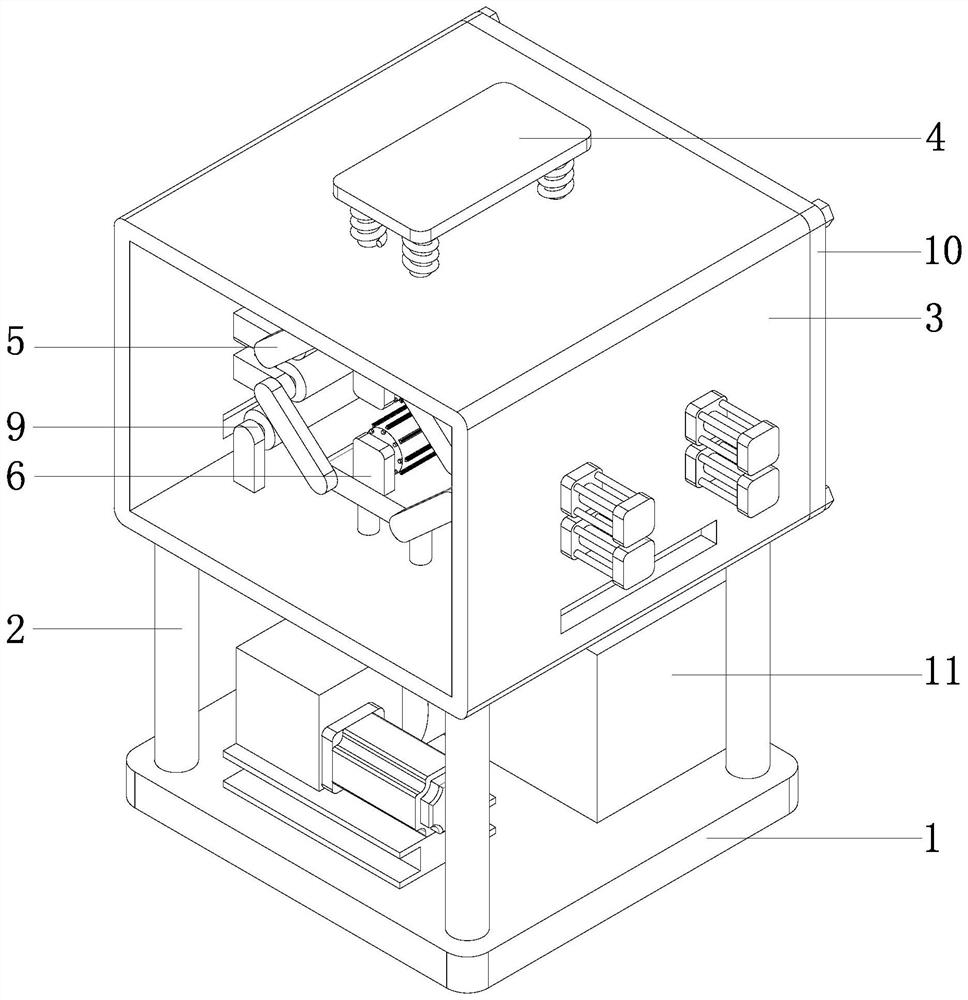

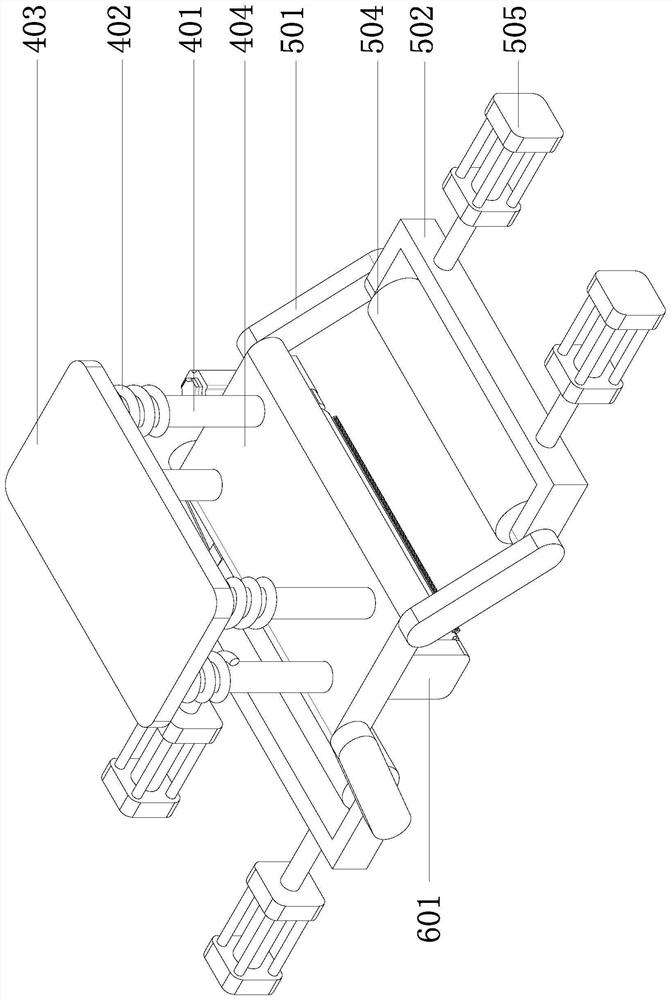

[0043] Embodiment 1, with reference to Figure 1-8 , a flexible customized digital blanket processing equipment, including, including double needle bed warp knitting machine, fabric dividing machine, digital printing machine, ironing equipment, cutting equipment and hemming machine, ironing equipment includes base plate 1, base plate 1 top The four corners of the outer walls are welded with support columns 2, the top of the base plate 1 is provided with an installation frame 3, the four corners of the bottom of the installation frame 3 are respectively welded on the top outer walls of the four support columns 2, and the inner walls of the top and bottom of the installation frame 3 are provided with Connecting mechanism 4, connecting mechanism 4 comprises four connecting rods 401, the spring 402 that is sleeved on the upper outer wall of the four connecting rods 401, the four corners of the bottom are respectively welded to the limiting plate 403 on the top outer wall of the fou...

Embodiment 2

[0047] Embodiment 2, with reference to figure 1 and Figure 9-10 , a flexible and customized digital blanket processing equipment, an installation plate 10 is connected to the outer wall of one side of the installation frame 3 by bolts, and a dust removal mechanism 11 is provided on the top outer wall of the bottom plate 1. A delivery pipe 1101 with a "U" shape on one side of the outer wall, a dust box 1102 connected to the top outer wall of the bottom plate 1 by bolts, a dust-proof net 1103 connected to the inner wall at the bottom end of the dust box 1102 by bolts, and a dust-proof net 1103 connected by bolts Be connected to the base 1104 on the top outer wall of the base plate 1, be connected by bolts to the ear dust removal fan 1105 on the top outer wall of the base 1104 and the connecting pipe 1106 that is sleeved on the inner wall of the dust box 1102 near the dustproof net 1103.

[0048] Further, connecting flanges are fixedly connected on the top and bottom outer wall...

Embodiment 3

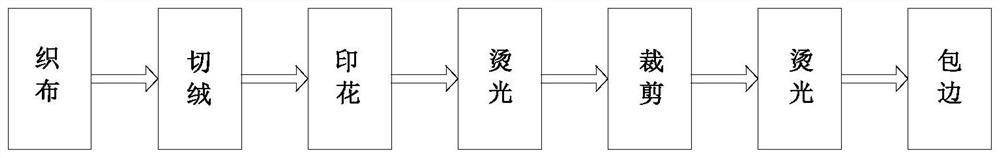

[0054] This embodiment discloses a processing method for a flexible customized digital blanket, which includes the following steps:

[0055] S1: Feed the yarn into the double-needle bed warp knitting machine, and use the double needle bed warp knitting machine to knit the yarn. The knitting speed is 650r / min, the number of warping processes is 385*4, and the weaving width is 208±2cm;

[0056] S2: After the weaving is completed, the gray cloth is sent to the fabric dividing machine for cashmere cutting, the wool height is set to 105mm, and the wool height error is set to 0.1mm;

[0057] S3: Send the gray cloth after velvet cutting into the digital printing machine, and the digital printing machine will print the pattern drawn on the computer in advance on the gray cloth, and dry the gray cloth without plate making and proofing;

[0058] S4: Send the printed fabric into the ironing equipment, start four servo cylinders 505 at the same time, the piston rods of the four servo cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com