Temperature control anti-cracking method for aqueduct in operation period

A temperature-controlled crack-prevention, operation period technology, applied in water conservancy projects, artificial waterways, bridge parts, etc., can solve the problems of heat release concentration, affecting the durability and safety of the structure, large amount of concrete and cement, etc., to achieve no pollution effect. , Easy to lay and paste, good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

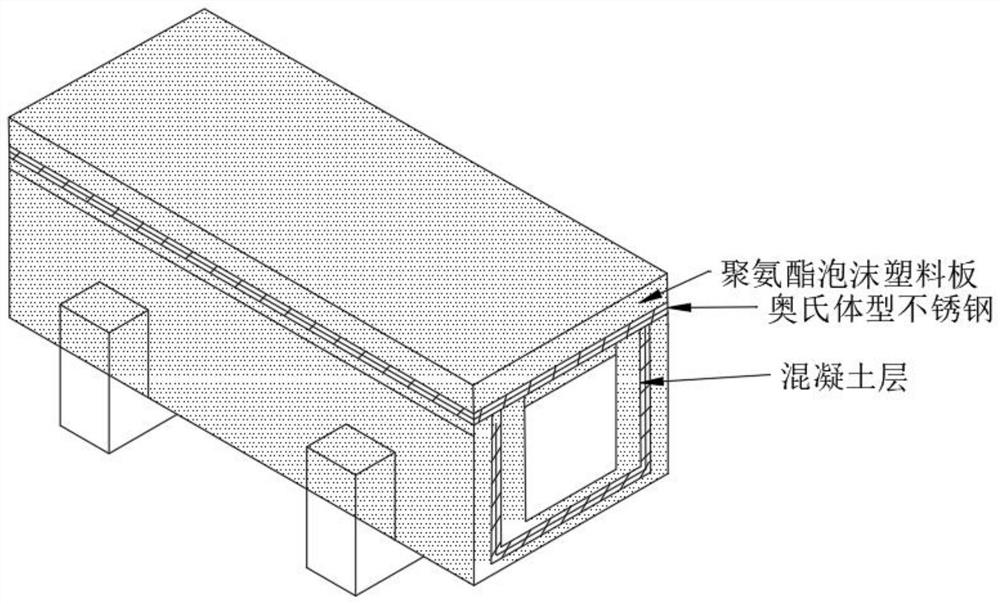

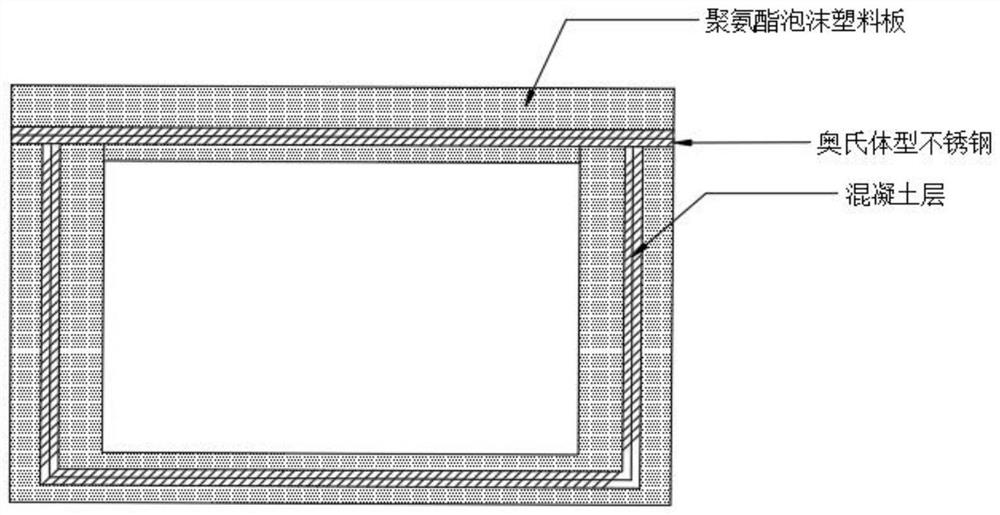

[0020] After pasting different thicknesses (2 cm, 3.5 cm, 5 cm) of polyurethane heat insulation on the outer surface of the aqueduct, the highest temperature of the aqueduct body appears on the top plate, and the temperature of the aqueduct body after different thicknesses of polyurethane heat insulation is lower than that of the aqueduct without heat insulation measures The temperature is significantly lower than that. The maximum tensile stress of the aqueduct body is also significantly lower than that of the aqueduct without heat insulation measures. Therefore, after the heat insulation measures are taken, the temperature difference between the inside and outside of the tank decreases, and the temperature stress caused by the temperature difference also decreases, especially the temperature tensile stress, which effectively prevents cracks. The surface temperature gradually decreases. But the thickness increases beyond a certain value, and the heat insulation effect is not...

Embodiment 2

[0038] After pasting different thicknesses (2 cm, 5 cm, 8 cm) of polyurethane insulation on the outer surface of the aqueduct, the lowest temperature of the aqueduct appeared on the east and west webs, and the temperature of the aqueduct body after different thicknesses of polyurethane insulation was comparable to that of the aqueduct without heat insulation measures ratio has increased significantly. The maximum tensile stress of the aqueduct body is also significantly lower than that of the aqueduct without heat insulation measures. Therefore, after taking heat insulation measures, the temperature gradient of the tank body decreases, and the temperature stress caused by the temperature difference also decreases, especially the temperature tensile stress, which effectively prevents cracks. The temperature gradually increased. But when the thickness increases beyond a certain value, the thermal insulation effect is not so obvious.

[0039] Table 9 The maximum temperature dif...

Embodiment 3

[0057] In summary, during the normal operation period of the aqueduct, in addition to normal maintenance, 3.5 cm thick polyurethane should be pasted on the outside of the east and west webs of the aqueduct, 5 cm thick polyurethane on the inside of the east and west webs of the aqueduct, and 5 cm thick polyurethane on the top side of the aqueduct. Polyurethane, 2 cm of polyurethane on the underside of the top plate, and 2 cm of polyurethane on the top and bottom of the web.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com