Intelligent window and preparation method thereof

A window and smart technology, applied in nonlinear optics, shading screens, instruments, etc., can solve the problem that electrochromic smart windows cannot operate at low temperatures, and achieve good low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

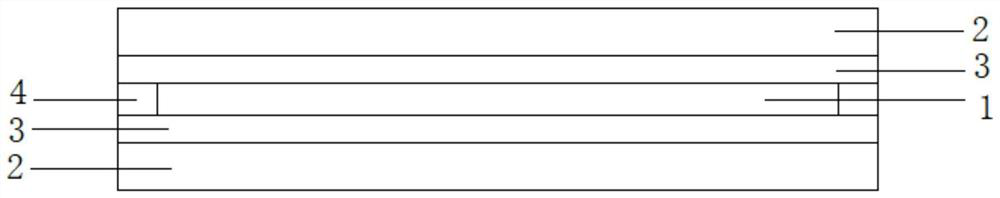

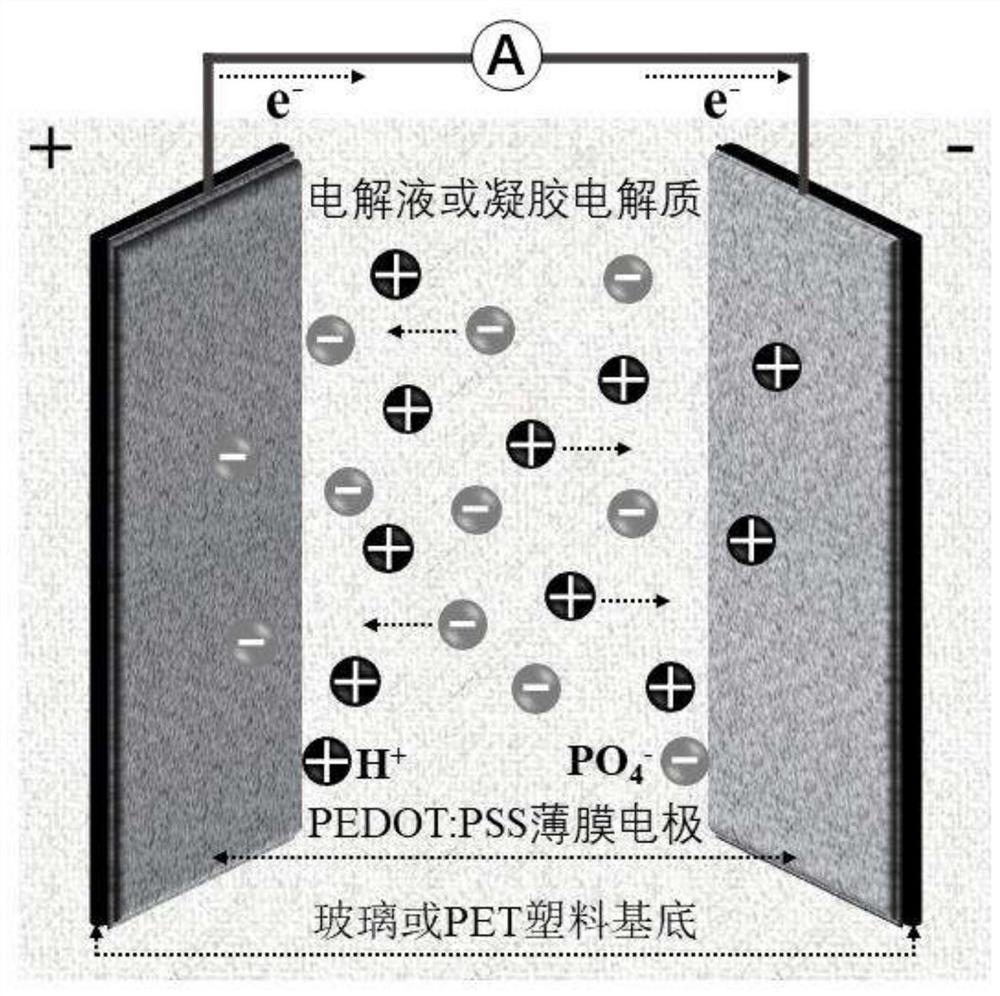

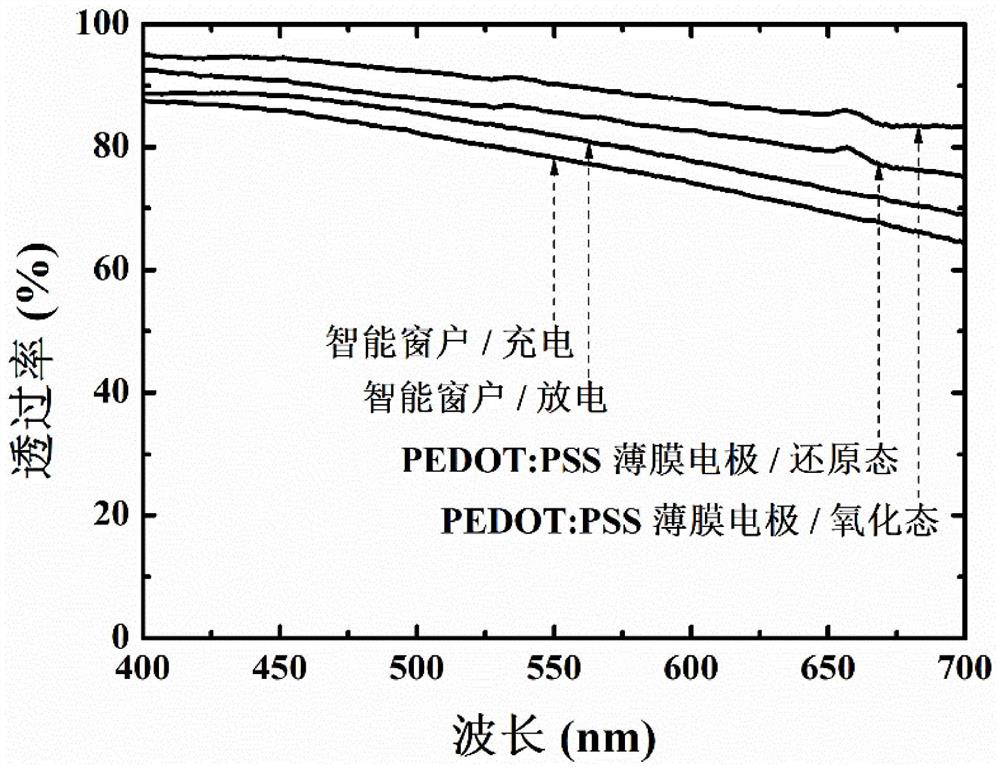

[0045] (1) Preparation of PEDOT:PSS thin film electrode: mix ethylene glycol and PH1000 in a mass ratio of 7:93, then add a fluorosurfactant dropwise to the mixture (based on the sum of the mass of ethylene glycol and PH1000 as 1g , the volume of fluorosurfactant is 0.5μL), stirred at room temperature for 8 hours to obtain PEDOT:PSS suspension, the PEDOT:PSS suspension was spin-coated on a cleaned glass substrate (thickness 2mm), spin-coated The speed is set to 800rpm, the spin-coating acceleration is set to 300rpm / s, the spin-coating time is set to 45s, and then dried on a hot plate, the drying temperature is set to 130°C, and the drying time is 10 minutes to obtain PEDOT:PSS thin film electrode, PEDOT: The thickness of the PSS suspension coating is 140nm;

[0046] (2) Preparation of electrolyte: Mix deionized water and ethylene glycol at a volume ratio of 1:1, then add phosphoric acid solution at 100 mg / mL and stir at room temperature for 2 hours to obtain phosphoric acid el...

Embodiment 2

[0052] (1) Preparation of PEDOT:PSS thin film electrode: mix ethylene glycol and PH1000 in a mass ratio of 7:93, then add a fluorosurfactant dropwise to the mixture (based on the sum of the mass of ethylene glycol and PH1000 as 1g , the volume of fluorosurfactant is 0.5μL), stirred at room temperature for 8 hours to obtain PEDOT:PSS suspension, the PEDOT:PSS suspension was spin-coated on a cleaned glass substrate (thickness 2mm), spin-coated The speed is set to 500rpm, the spin-coating acceleration is set to 300rpm / s, the spin-coating time is set to 45s, and then dried on a hot plate, the drying temperature is set to 130°C, and the drying time is 10 minutes to obtain a PEDOT:PSS thin film electrode, PEDOT: The thickness of the PSS suspension coating is 200nm;

[0053] (2) Preparation of electrolyte: Mix deionized water and ethylene glycol at a volume ratio of 1:1, then add phosphoric acid solution at 100 mg / mL and stir at room temperature for 2 hours to obtain phosphoric acid ...

Embodiment 3

[0058] (1) Preparation of PEDOT:PSS thin film electrode: mix ethylene glycol and PH1000 in a mass ratio of 7:93, then add a fluorosurfactant dropwise to the mixture (based on the sum of the mass of ethylene glycol and PH1000 as 1g , the volume of fluorosurfactant is 0.5μL), stirred at room temperature for 8 hours to obtain PEDOT:PSS suspension, the PEDOT:PSS suspension was spin-coated on a cleaned glass substrate (thickness 2mm), spin-coated The speed is set to 1000rpm, the spin-coating acceleration is set to 300rpm / s, the spin-coating time is set to 45s, and then dried on a hot plate, the drying temperature is set to 130°C, and the drying time is 10 minutes to obtain PEDOT:PSS thin film electrode, PEDOT: The thickness of the PSS suspension coating is 125nm;

[0059] (2) Preparation of electrolyte: Mix deionized water and ethylene glycol at a volume ratio of 1:1, then add phosphoric acid solution at 100 mg / mL and stir at room temperature for 2 hours to obtain phosphoric acid e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com