Intelligent inert injection, cooling and fire prevention system for goaf under coal mining condition and implementation method

A technology for gobs and conditions, applied in the direction of fire prevention, dust prevention, mining equipment, etc., to achieve the effects of improving gas utilization, lowering temperature, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

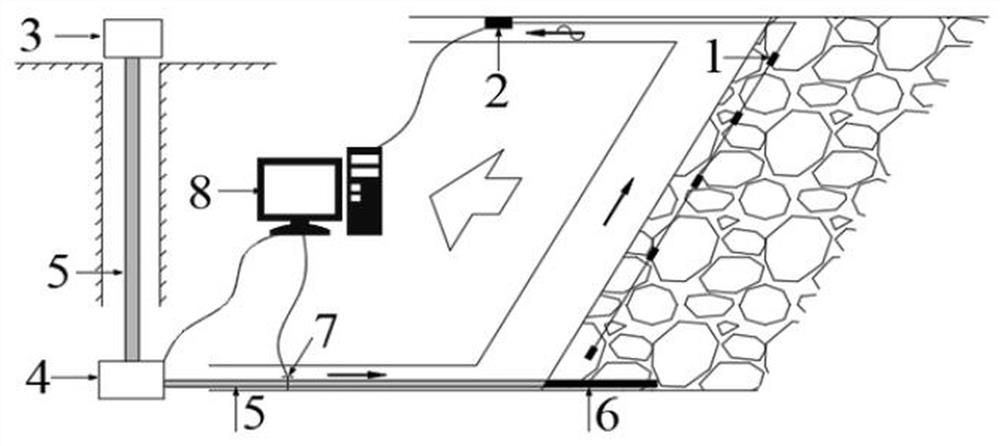

[0098] The present invention also provides an implementation method of the intelligent inert injection and cooling fire protection system in the goaf under the coal mining conditions as described above, and the implementation method includes the following steps:

[0099] Step 1: Obtain the basic parameters of the goaf and the temperature data before inert gas injection monitored by the temperature measurement module, and input the basic parameters of the goaf and the temperature data before the injection of the inert gas into the gob for inert cooling and fire protection In the simulation software 8; wherein, the basic parameters of the goaf include the advancing speed of the goaf working face, the inlet air temperature, the return air temperature and the ventilation resistance;

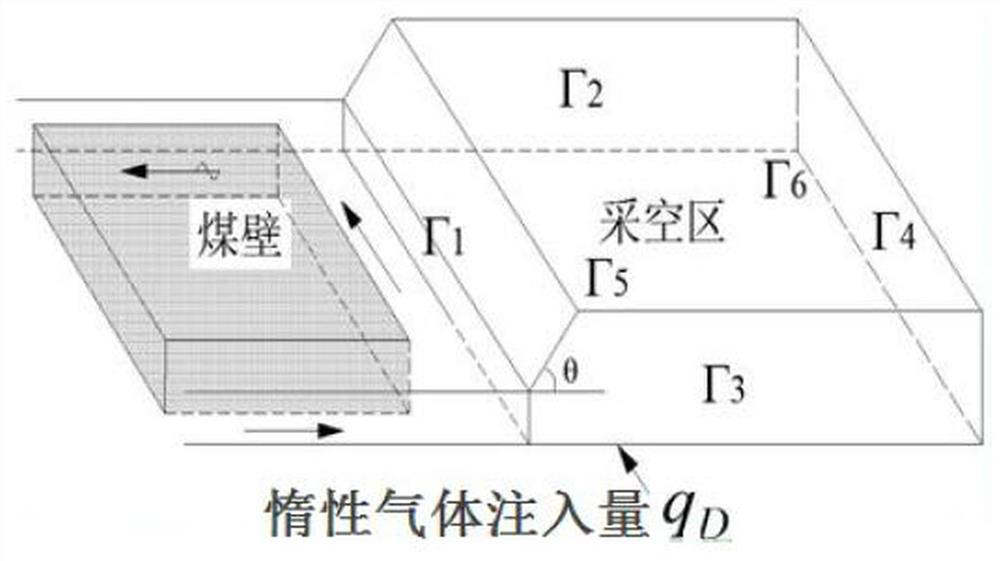

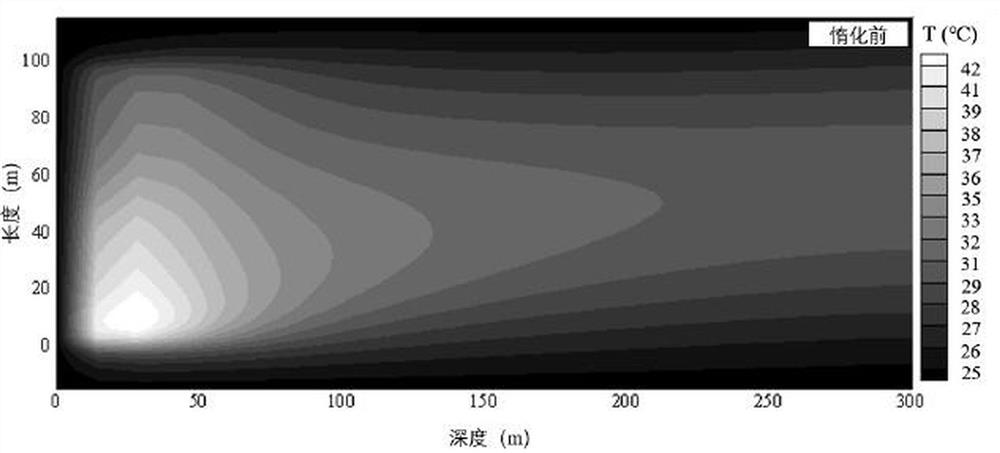

[0100] Step 2, based on the basic parameters of the goaf and the temperature data before the inert gas injection, the goaf injection cooling fire prevention simulation software 8 simulates the positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com