Throttle orifice plate suitable for high-temperature exhaust system

A technology of throttling orifice and exhaust system, which is applied in pipeline system, gas/liquid distribution and storage, pipe/pipe joint/fitting, etc., which can solve the problems of high replacement cost, back pressure adjustment, long stabilization time, and back pressure The problem of high cost of regulating valves, to achieve the effect of simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

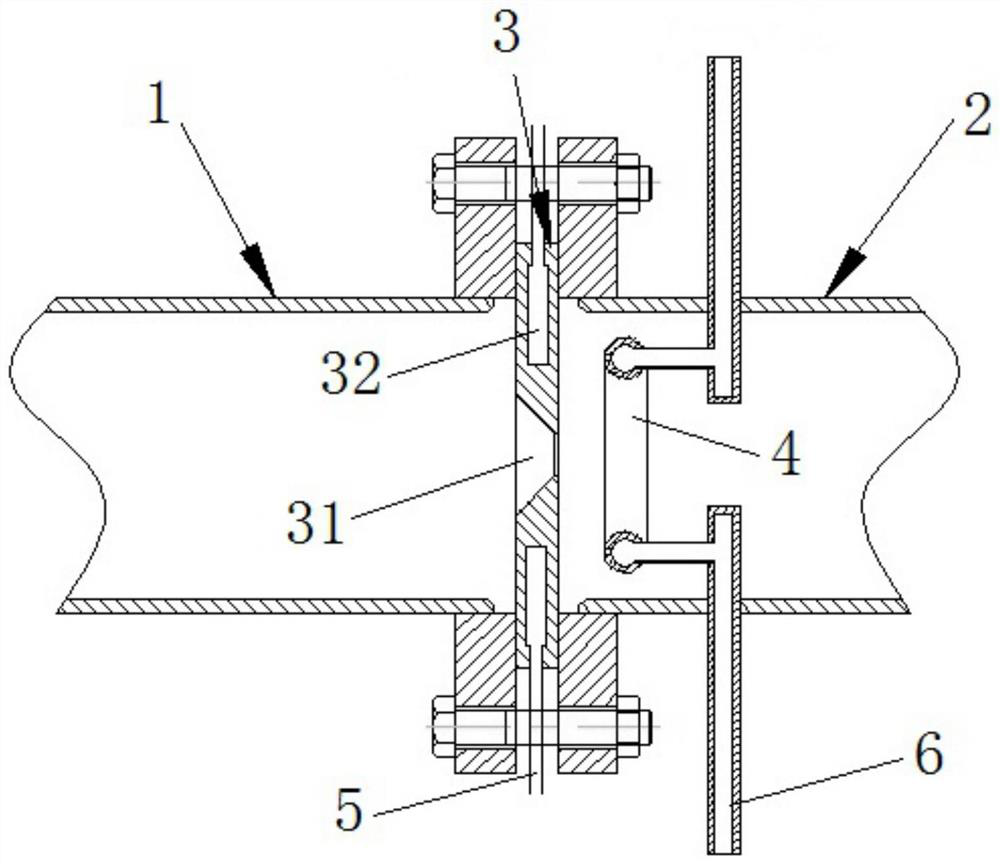

[0022] The disclosed examples will be described more fully with reference to the accompanying drawings, in which some, but not all, of the disclosed examples are shown. In fact, many different examples may be described and should not be construed as limited to those set forth herein. Rather, these examples are described so that this disclosure will be thorough and complete, and will fully convey the scope of the disclosure to those skilled in the art.

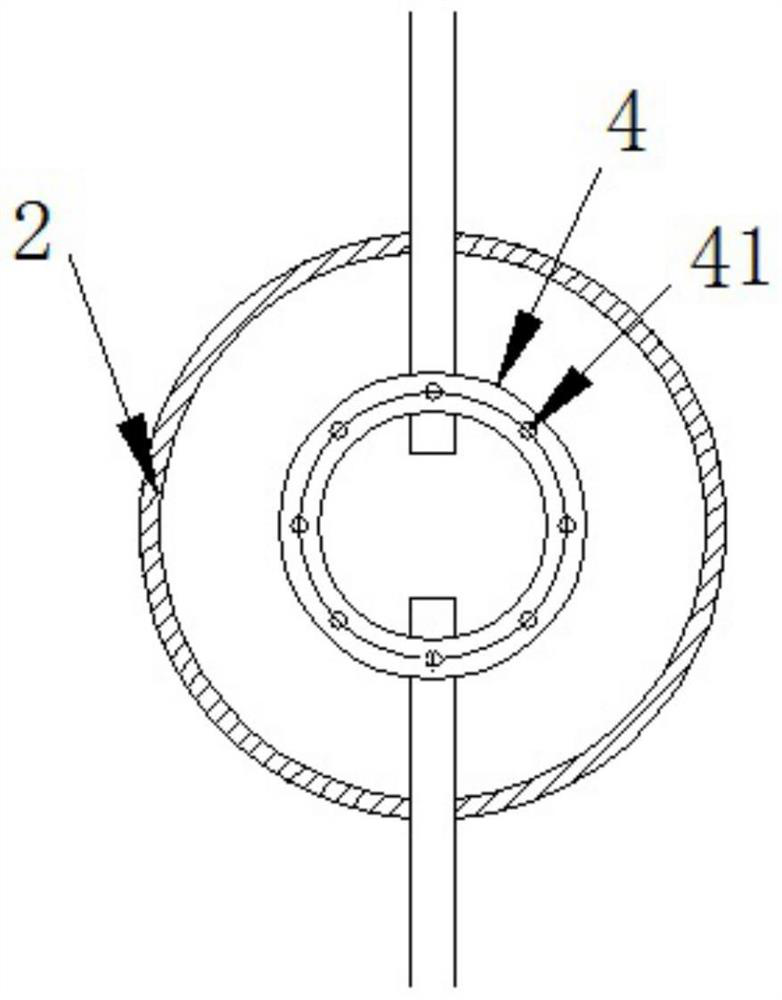

[0023] A specific embodiment is: provide a throttling orifice suitable for a high-temperature exhaust system, the throttling orifice is installed between the outlet of the high-temperature exhaust pipe and the inlet of the low-temperature exhaust pipe, and the high-temperature exhaust is subjected to the throttling orifice throttling effect;

[0024] The throttling orifice has a central throttling hole, the throttling orifice has an annular cooling cavity, the annular cooling cavity is concentrically arranged with the central ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com