Car lamp with miniature magnetic induction power generation structure

A magnetic induction, miniature technology, applied in the field of car lights, can solve the problems of unutilized airflow energy and vehicle kinetic energy loss, and achieve the effect of improving energy utilization and reducing energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

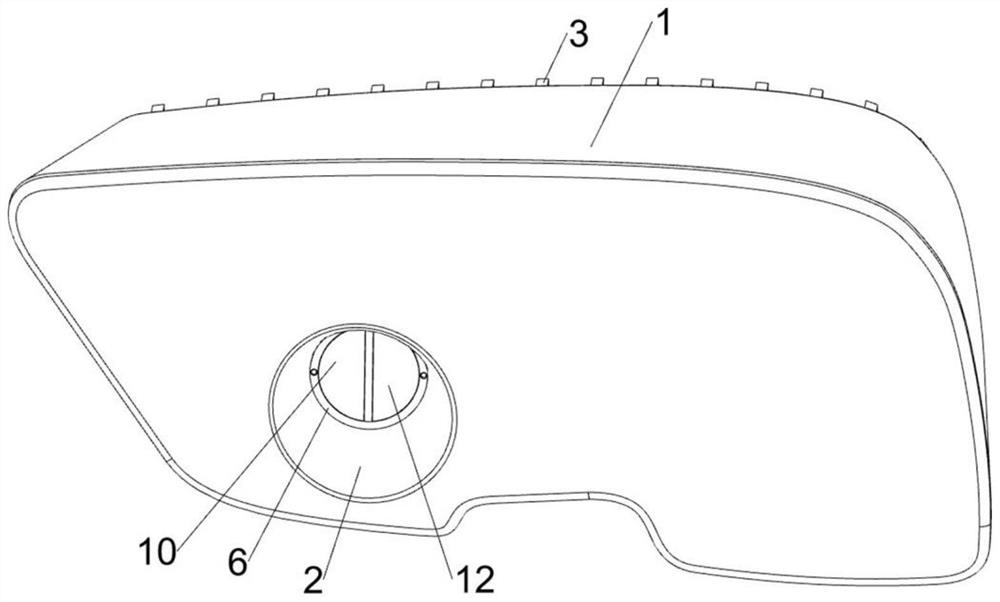

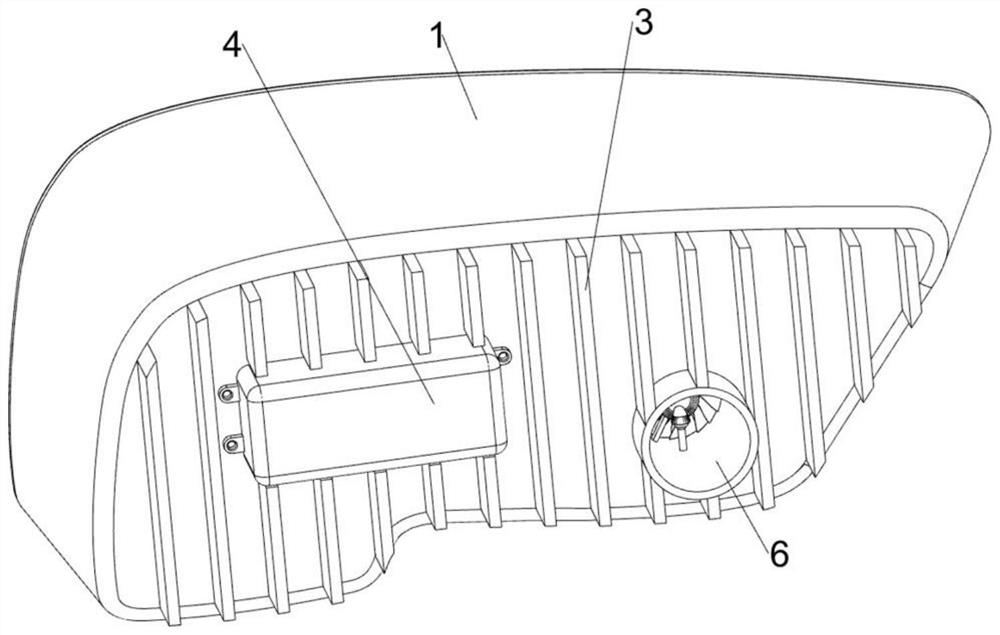

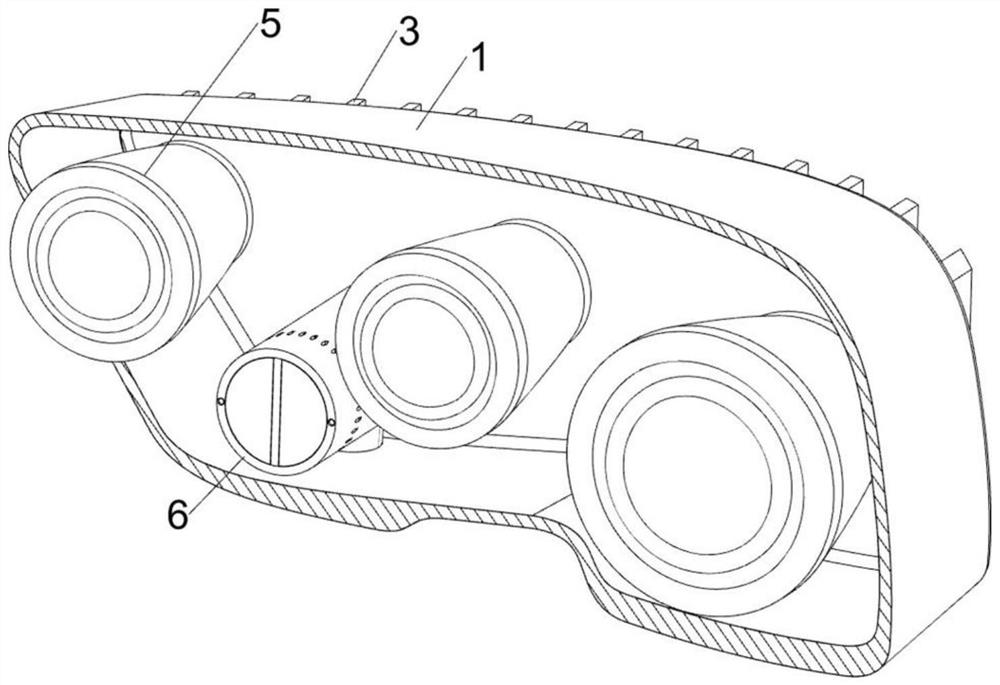

[0036] A car lamp with a miniature magnetic induction power generation structure, such as Figure 1-5 As shown, it includes a housing 1, a heat sink 3, a battery 4, an LED light source 5 and a magnetic induction power generation system; an air inlet 2 is opened on the front of the housing 1; several Heat sink 3; battery 4 is installed at the rear of housing 1, and the outer surface of battery 4 is in contact with heat sink 3; three LED light sources 5 are installed at the inner rear of housing 1; A magnetic induction power generation system for generating power by kinetic energy; three LED light sources 5 are electrically connected to the battery 4; the magnetic induction power generation system is electrically connected to the battery 4.

[0037]When using the light with a miniature magnetic induction power generation structure, first install it to the corresponding position on the front of the vehicle, and then when the vehicle is moving and accelerating, the front of the ve...

Embodiment 2

[0039] On the basis of Example 1, such as image 3 , Image 6 and Figure 10-13 As shown, the magnetic induction power generation system includes a wind power generation system that utilizes wind energy to generate electricity. The wind power generation system includes a mounting cylinder 6, a fixed bearing frame 16, a first shaft rod 17, a power generation fan blade 18, a bevel gear plate 19, and a bevel gear 20. , the second rotating shaft rod 21, the first fixed disc 22, the first magnet 23, the base 24 and the first coil 25; the rear part of the inner side of the housing 1 is installed with a mounting cylinder 6, and the outer ring of the front surface of the mounting cylinder 6 is connected to the The rear side ring surface of the air inlet hole 2 on the housing 1 is fixed; the rear side of the installation cylinder 6 is in an open state; the middle part of the installation cylinder 6 is fixedly connected with a fixed bearing frame 16; the middle part of the fixed bearin...

Embodiment 3

[0043] On the basis of Example 2, such as Figure 10 and Figure 14-1 As shown in 5, the magnetic induction power generation system also includes a kinetic energy power generation system that uses kinetic energy to generate electricity. The kinetic energy power generation system includes a mounting box 26, a mounting chassis 27, a first mounting vertical plate 28, a fixed rod 30, a swing rod 31, and a mounting plate. 32. Control rod 34, vertical bearing frame 35, third rotating shaft rod 36, transmission disc 37, fixed toothed disc 38, second return spring 39, ratchet 40, ratchet wheel 41, second fixed disc 42, second installation The vertical plate 43 and the second coil 44; the installation box 26 is installed in the middle part of the left side of the installation cylinder 6; the inner bottom of the installation box 26 is bolted to the installation chassis 27; the rear side of the upper surface of the installation chassis 27 is welded with the first installation vertical pl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap