Connector detection method and device based on machine vision

A technology of machine vision and detection method, applied in the field of visual detection, which can solve the problems of sensitivity to changes in environmental factors, high false detection rate of detection methods, and high labor costs, and achieve the effects of weakening random noise, saving manpower and time, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

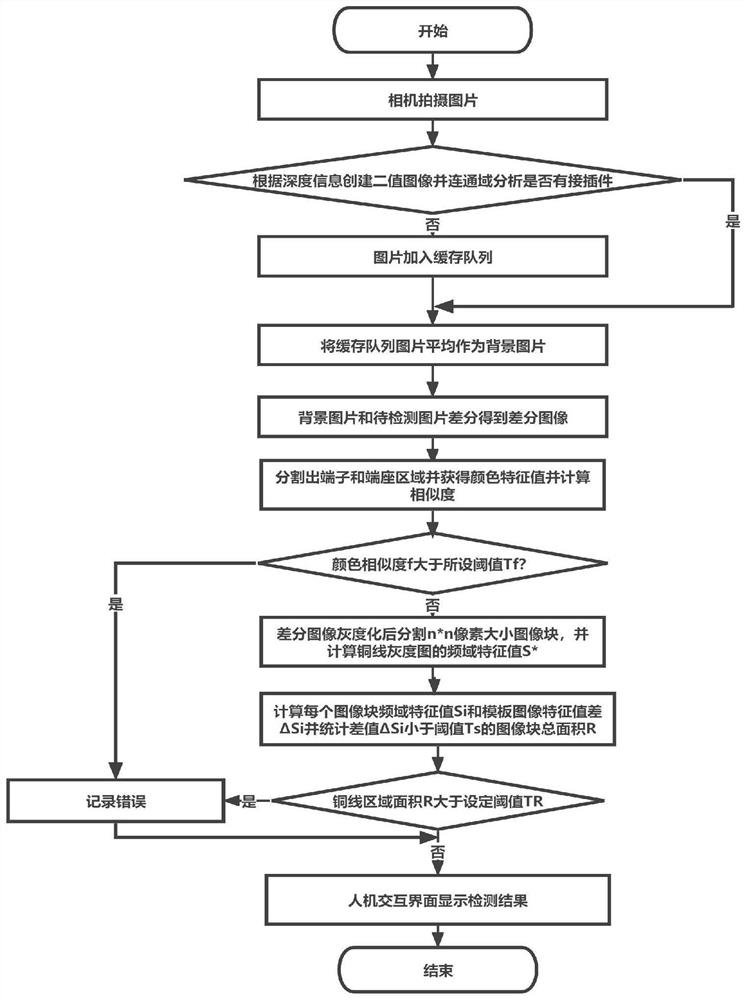

Method used

Image

Examples

Embodiment Construction

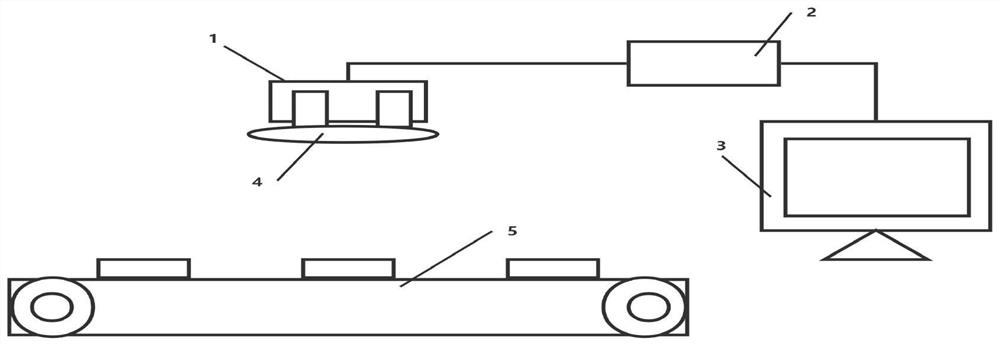

[0045] In this example, if figure 1 As shown, a terminal detection device based on machine vision includes: an image processing unit, an image acquisition unit, a mechanical transmission unit, and a human-computer interaction unit;

[0046] Wherein, the mechanical transmission unit 5 is a conveyor belt moving at an appropriate speed to drive the connectors to be detected to move.

[0047] The image acquisition unit includes: an image acquisition element and an adjustable ring light source. The image acquisition element adopts a binocular camera 1 modeled as INTEl D435. The ring light source 4 is placed under the camera, and the light intensity can be adjusted through the controller. The binocular camera 1 is placed horizontally directly above the mechanical transmission unit, and the optical center is vertical to the detection plane, and the two optical center lines are parallel and placed above the detection line in the same direction as the detection line, for acquiring scen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com