Avalanche photodiode and manufacturing method thereof

An avalanche photoelectric and diode technology, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of thickening of avalanche photodiodes and poor performance of avalanche photodiodes, and achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

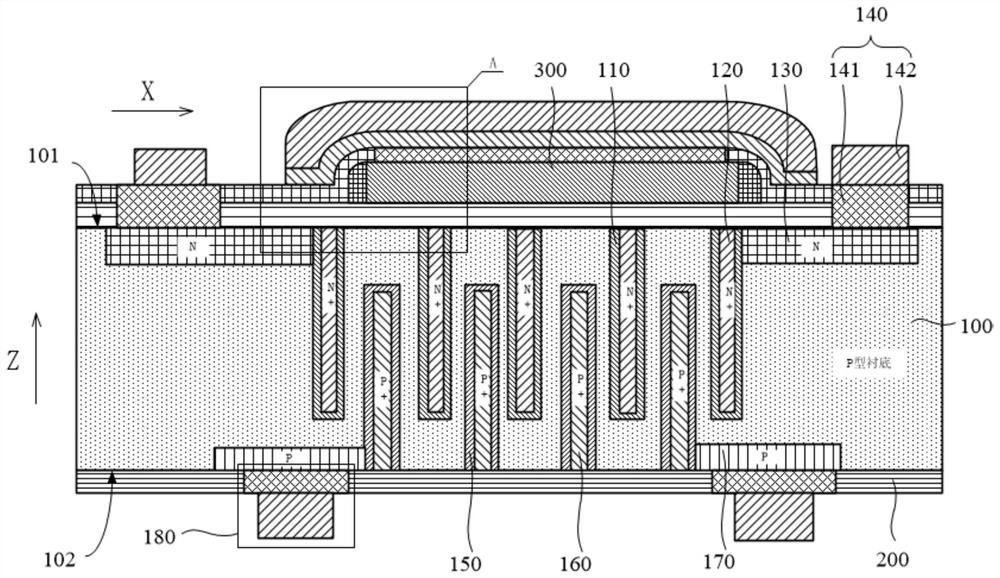

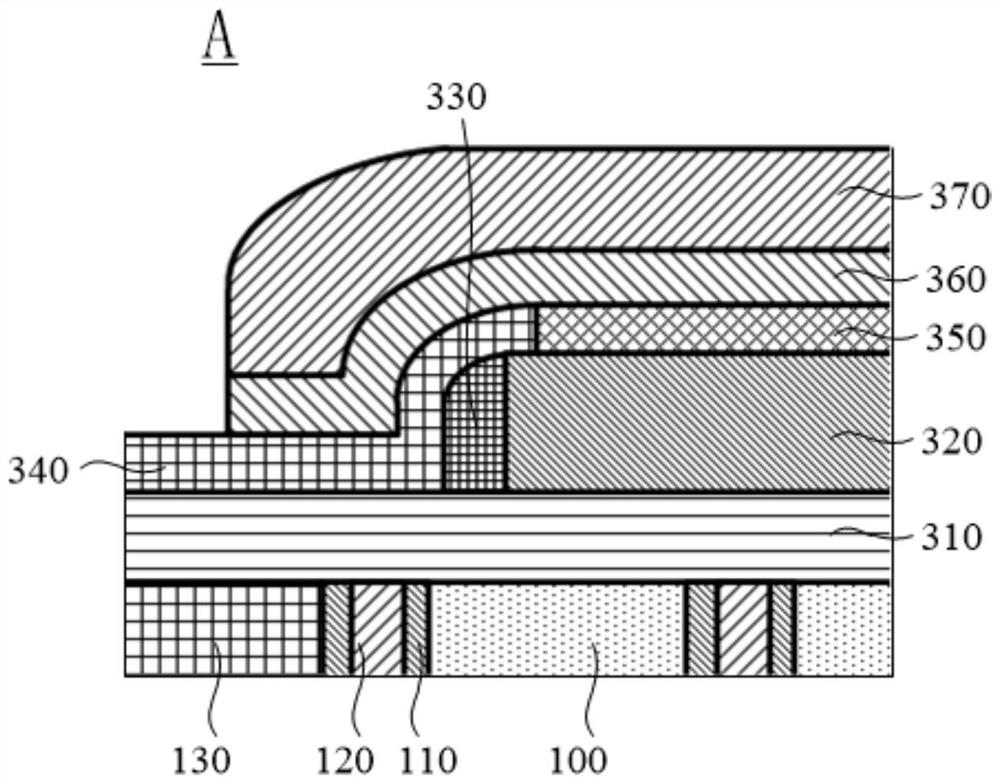

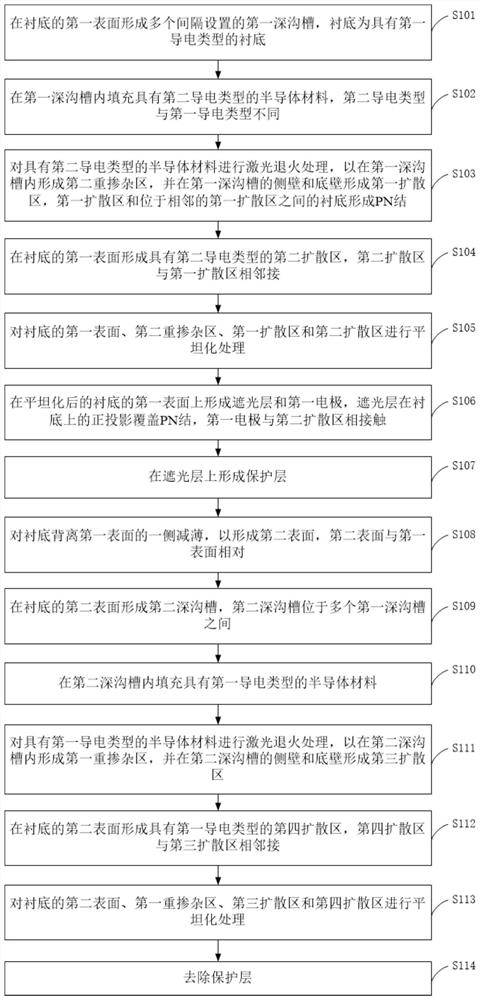

[0049] In order to improve the performance of the avalanche photodiode, an embodiment of the present application provides an avalanche photodiode, by setting a plurality of first diffusion regions at intervals on the first surface of the substrate, and the conductivity type of the first diffusion region is different from that of the substrate , so that the first diffusion region and the substrate between adjacent first diffusion regions form a PN junction. The PN junction is a lateral PN junction. By adjusting the depth of the first diffusion region and the distance between adjacent first diffusion regions, the length and thickness of the depletion region of the PN junction can be adjusted to increase the size of the depletion region, thereby improving Performance of avalanche photodiodes. In addition, each first diffusion region forms a PN junction with its adjacent substrate, the number of avalanche photodiodes in the embodiment of the present application is at least two, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com