Conductive heating device for eliminating conductive heating deformation of ultrathin metal plate

A conductive heating and metal plate technology, applied in the direction of electric heating devices, ohmic resistance heating, ohmic resistance heating parts, etc., can solve problems such as difficulty in meeting simulation requirements, sample failure and damage, compression instability, etc., to reduce current density, The effect of reducing thermal stress and avoiding unstable bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

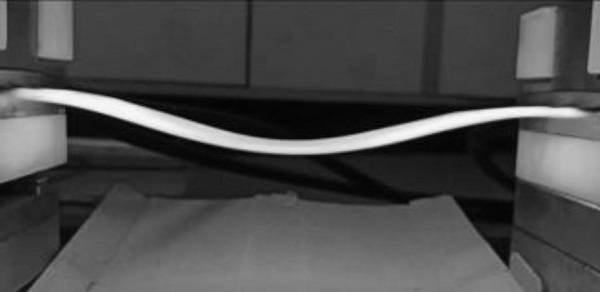

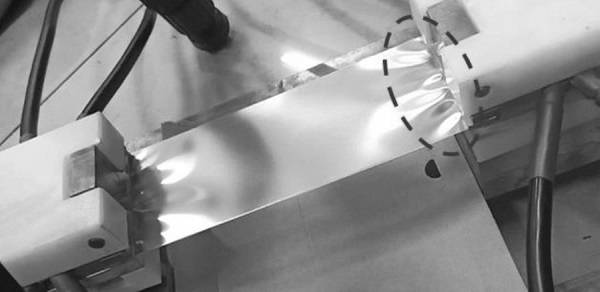

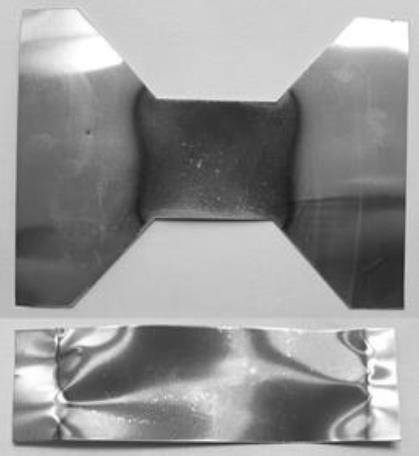

[0032] The conductive heating device of the embodiment of the present invention can realize heating of an ultra-thin metal plate with a thickness of 0.03-0.15 mm at a heating rate of 10-1500° C. / s. Wherein, the heating rate depends on the thickness of the metal plate. Specifically, the greater the thickness of the metal plate, the lower the corresponding heating rate.

[0033] For example, in an applicable scenario, the ultra-thin metal plate is an electrode plate for a lithium battery, and the thickness can be less than 0.15 mm, and the thickness range is further between 0.04 and 0.1 mm, and the thickness range is further between 0.05 and 0.075 mm. between. In this scenario, the conductive heating device can achieve a heating rate above 1000°C, and can heat the electrode plate for lithium batteries to the desired temperature in a very short time.

[0034] In another expanded application scenario, the conductive heating device of this embodiment can also heat thicker metal p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com