Non-setting adhesive remover homogenizing device based on environment-friendly formula and preparation method thereof

A technology for removing agents and formulations, applied in detergent compounding agents, chemical instruments and methods, mixers with rotary stirring devices, etc. The effect of protecting the beaker, improving the stirring efficiency and reducing the difficulty of stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment is a specific implementation of the self-adhesive remover uniform device based on the environmental protection formula.

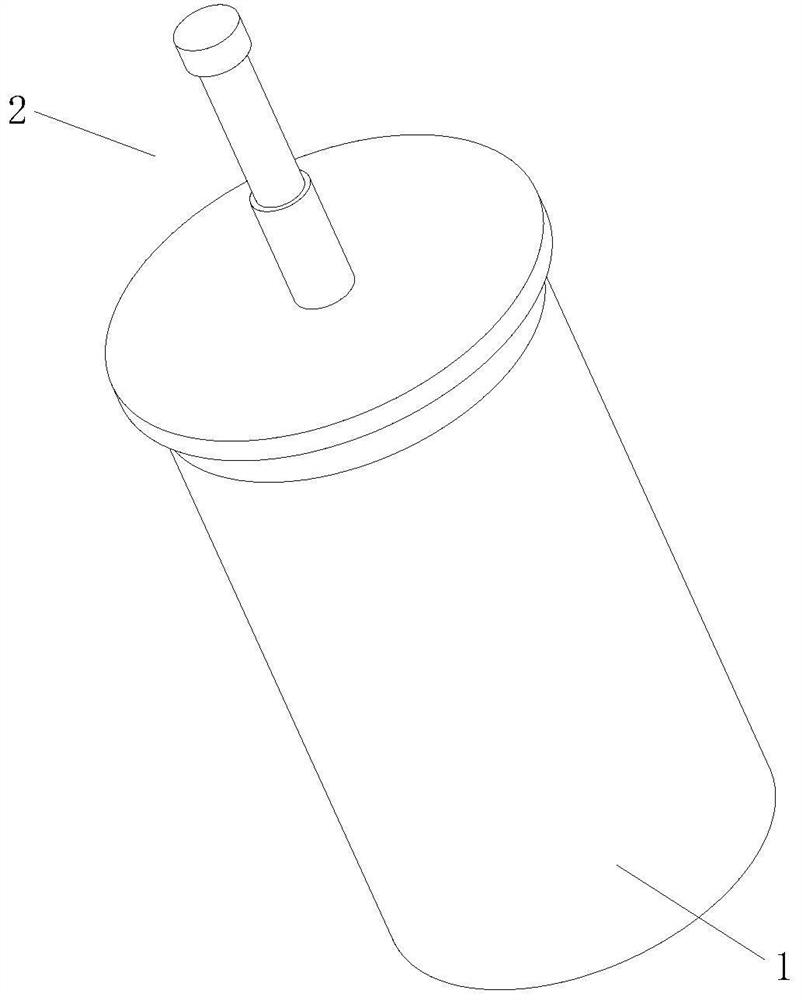

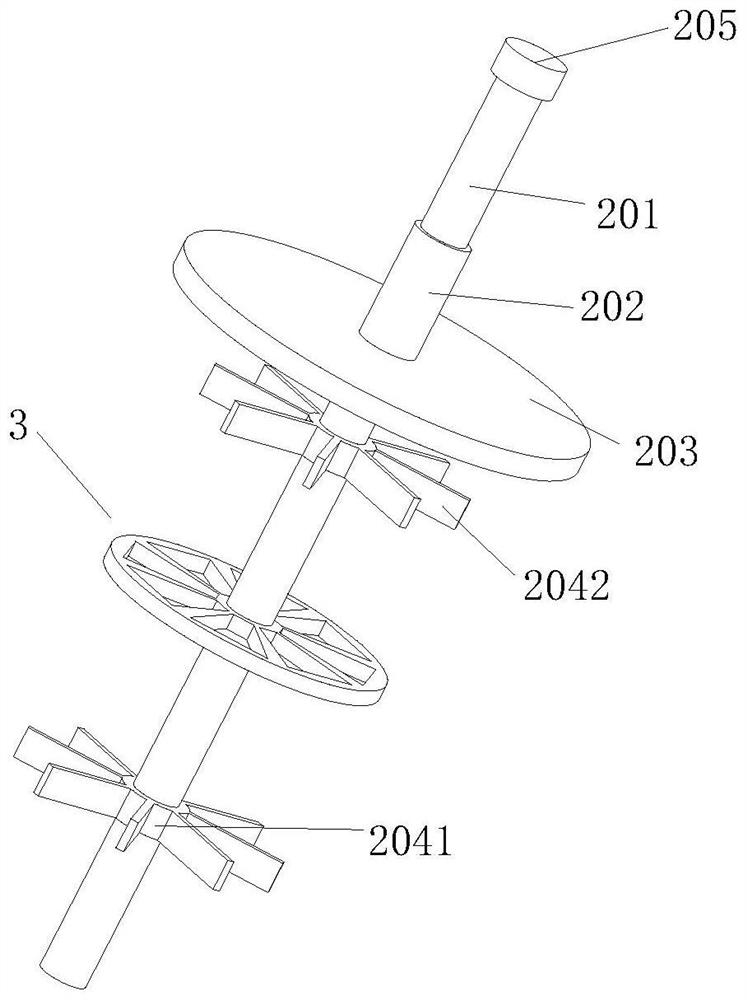

[0042] see Figure 1-7 , a self-adhesive remover uniform device based on an environmentally friendly formula and a preparation method thereof, comprising a beaker 1, the interior of the beaker 1 is provided with a stirring mechanism 2 and a stabilizing mechanism 3;

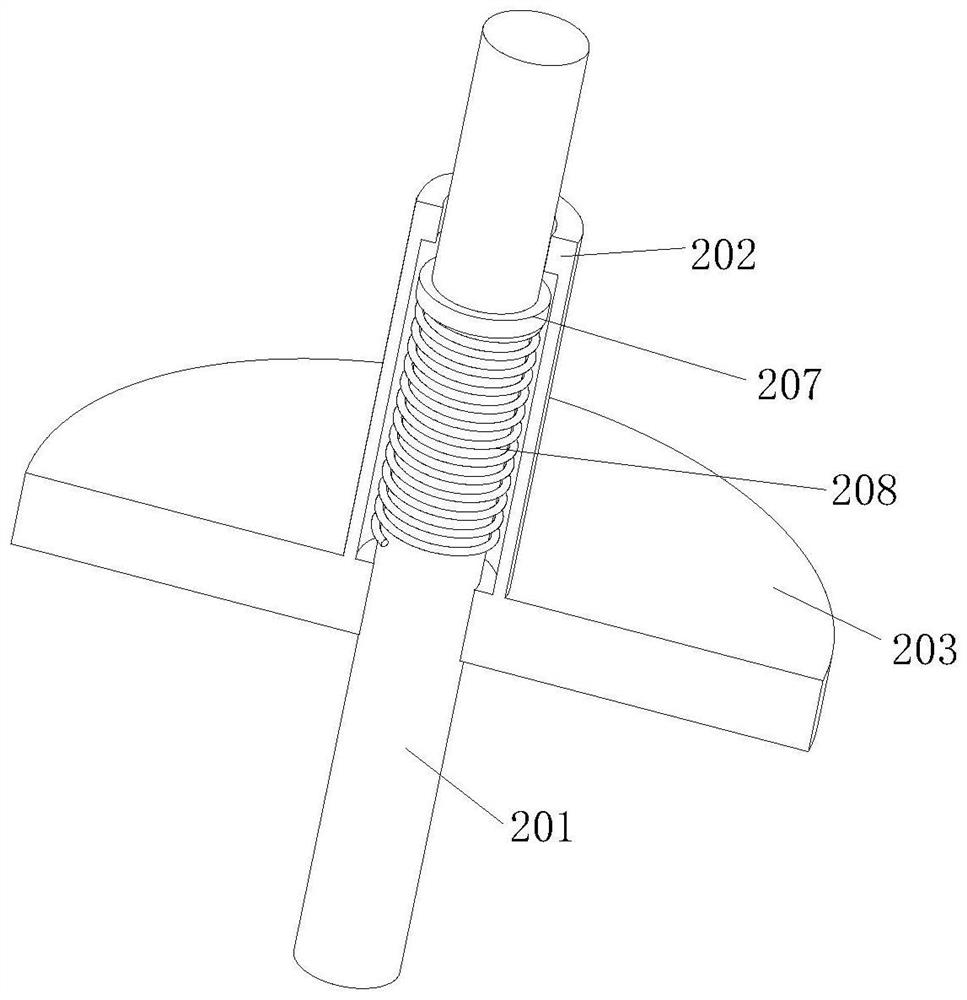

[0043] The stirring mechanism 2 includes a rotating rod 201, and the outer wall of the rotating rod 201 is fixedly connected with a support piece 207 near the top position, and the outside of the support piece 207 is sleeved with a sleeve 202. The bottom is fixedly connected with a top cover 203, and a spring 208 is movably connected between the top of the contact piece 207 and the inner top of the sleeve 202, and the spring 208 is sleeved on the outer wall of the rotating rod 201, and the rotating rod 201 The bottom end of the top cover 203 runs through the center of th...

Embodiment 2

[0063] This example is a specific implementation of the preparation method of the self-adhesive remover based on an environmentally friendly formula.

[0064] The preparation method of the self-adhesive remover based on environmental protection formula comprises following specific steps,

[0065] S1: Put 75-90 parts of ethyl acetate in beaker 1;

[0066] S2: Put 0 to 15 parts of N,N-dimethylacetamide in beaker 1, and use a homogenizing device to stir until uniform;

[0067] S3: Put 5 parts of fatty alcohol polyoxyethylene ether sodium sulfate into beaker 1, and use a homogenizing device to stir until uniform;

[0068] S4: Put 5 parts of simethicone oil with a viscosity of 50 into the beaker 1, and use a homogenizing device to stir until uniform;

[0069] S5: Put the beaker 1 in an ultrasonic cleaning machine and vibrate at 28 kHz for 2 minutes.

[0070] Through the above technical scheme, the proportion of the main components of the self-adhesive remover is as follows:

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com