UB hanging plate automatic bending machine

A bending machine, automatic technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of troublesome bending engineering, low work efficiency, cumbersome process, etc., to reduce work intensity and difficulty, and improve production efficiency. , the effect of simple and easy work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

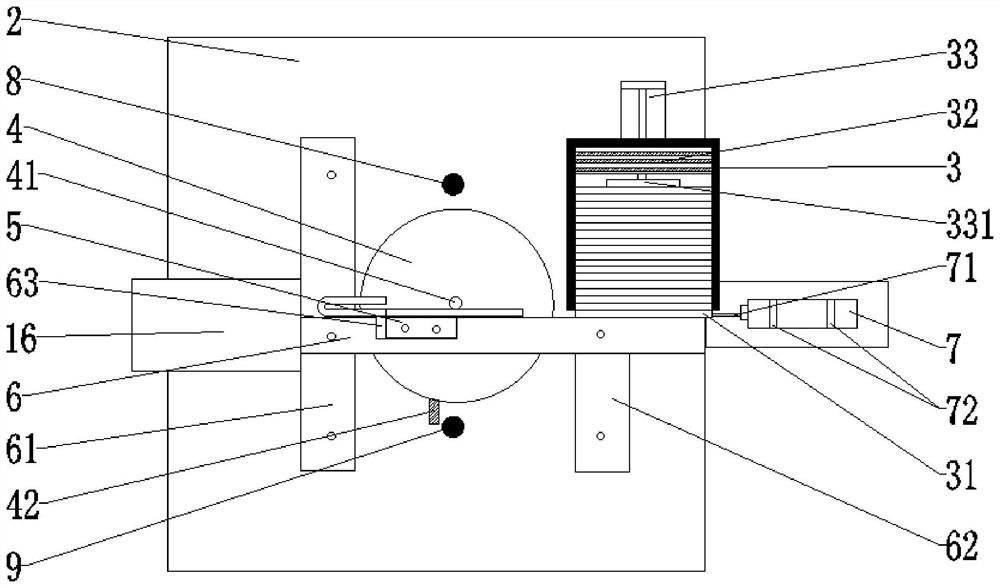

[0026] Embodiment 1: as figure 1 , figure 2 A UB hanging plate automatic bending machine shown is composed of a power device 1, a bending part and a frame 2, wherein the power device 1 is installed on the lower side of the frame 2, and the bending part is located above the power device 1. The output shaft 111 of the power device 1 is connected to the curved part, wherein the curved part includes a material box 3, a turntable 4, a moving module 5, and a fixed module 6, wherein: the center of the surface of the turntable 4 is provided with a vertical shaft 41, and the moving module 5 Fixed on the turntable 4, can rotate together with the turntable 4, and is installed on the first fixed mold base 61 one end of frame 2 mesa surface grooves 63 gap adaptation, the magazine 3 is fixed on the second One end of the two fixed mold bases 62, its discharge port 31 is directly opposite to the inner surface of the fixed module 6, and the fixed module 6 is fixed by the first fixed mold bas...

Embodiment 2

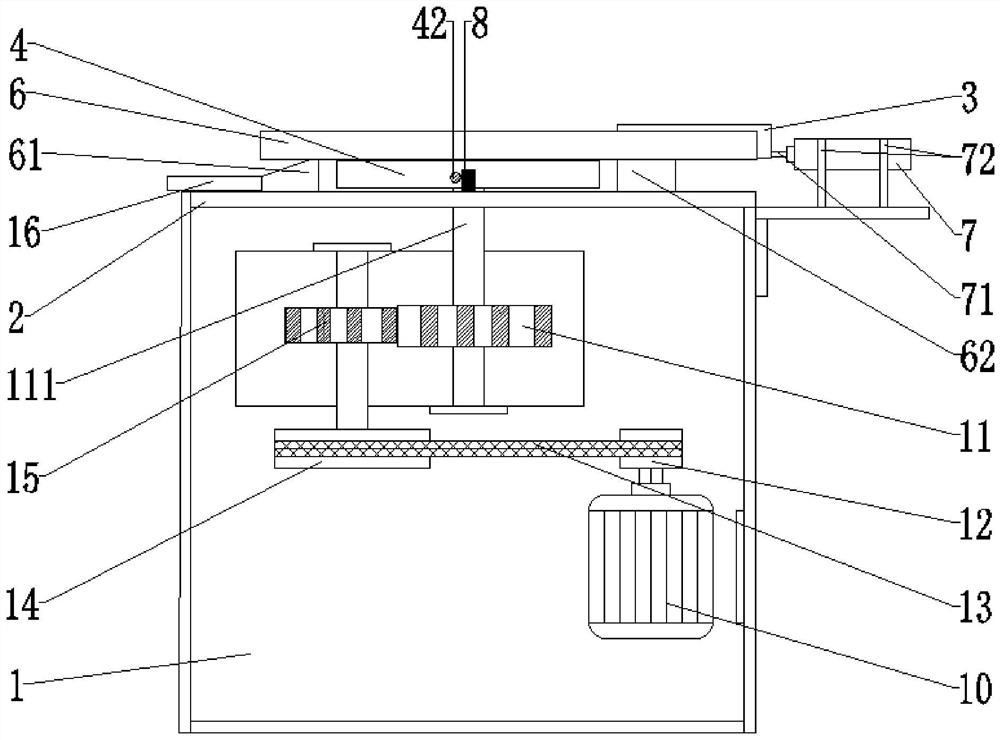

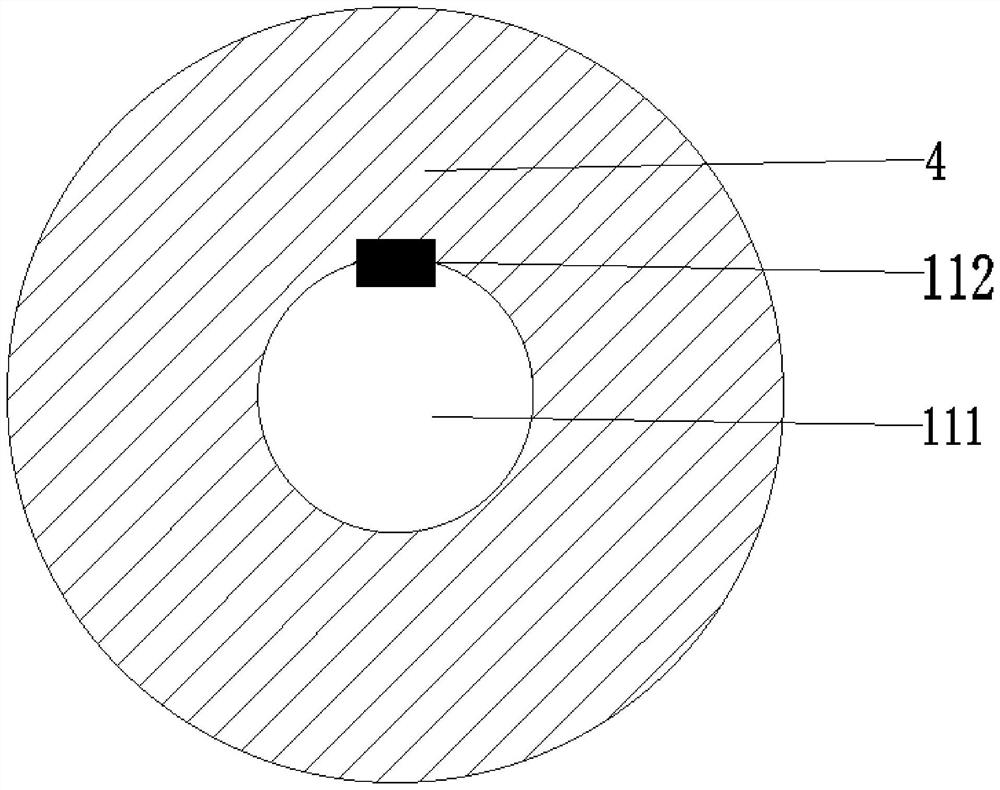

[0027] Embodiment 2: as figure 2 , image 3 , Figure 4 As shown, on the basis of Embodiment 1, this equipment optimally designs the connection between the power unit 1 and the turntable 4, that is, the output shaft 111 of the power unit 1 is connected to the center of the turntable 4 with a key. During work, the motor 10 in the power unit 1 is connected with the small pulley 12, and the motor 10 drives the small pulley 12 to rotate, and the small pulley 12 drives the large pulley 14 to rotate through the belt 13, so as to reach the first deceleration, and the large pulley 14 is the same as the pinion 15. Shaft connection, big belt pulley 14 drives pinion 15 to rotate, and pinion 15 side is equipped with bull gear 11, and pinion 15 rotates and drives bull gear 11 to rotate, reaches the second deceleration, and key 112 in bull gear 11 output shaft 111 and The key 112 groove fits inside the center of the lower part of the turntable 4. When the gear wheel 11 rotates, the outpu...

Embodiment 3

[0028] Embodiment 3: as figure 1As shown, on the basis of Embodiment 1, the fixed module 6 and the moving module 5 of this equipment are optimally designed in terms of fixing methods. In this embodiment, there are two fixed mold bases. The first fixed mold base 61 is fixed on the frame 2 on the side of the feeding trough 16 and is connected with the lower material trough 16. The second fixed mold base 62 is located on the frame 2 on the side of the material box 3. Above, two fixed die seats stand opposite each other on both sides of the turntable 4, and there are gaps between the two fixed die seats and the edge of the turntable 4. The fixed module 6 is located on the upper surface of the first fixed mold base 61 and the second fixed mold base 62, and openings are provided in both ends, which pass through the strip-shaped openings in the first fixed mold base 61 and the second fixed mold base 62 respectively. Bolts are connected, and the top and bottom ends of the bolts are f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com