Automatic welding tool for steel cladding and air pipe

A welding tooling and automatic welding technology, used in welding accessories, welding equipment, auxiliary welding equipment, etc., can solve the problems of low welding efficiency, and achieve the effects of reliable connection, stable clamping force, and convenient disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

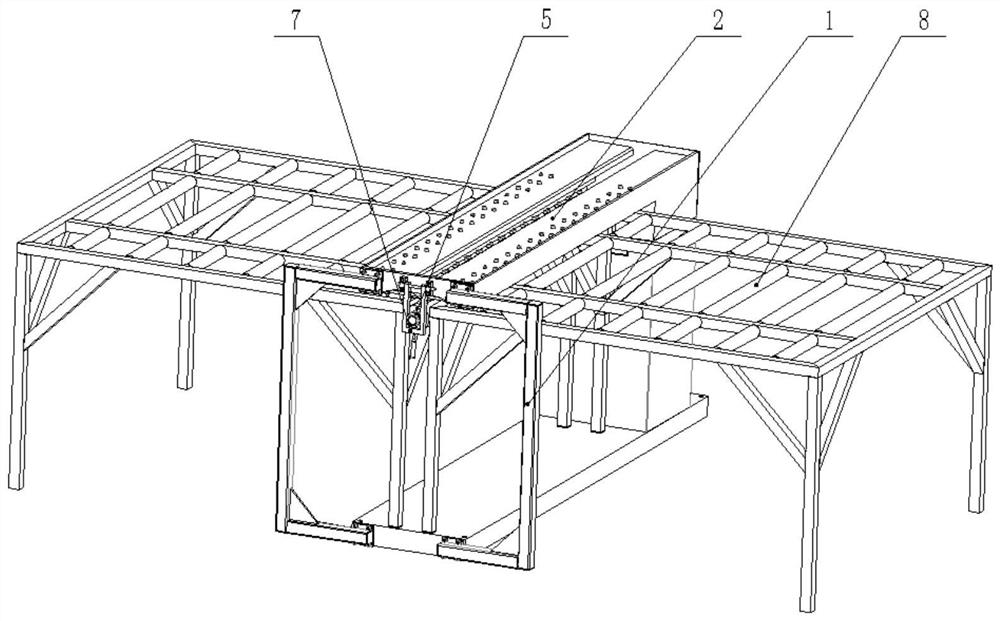

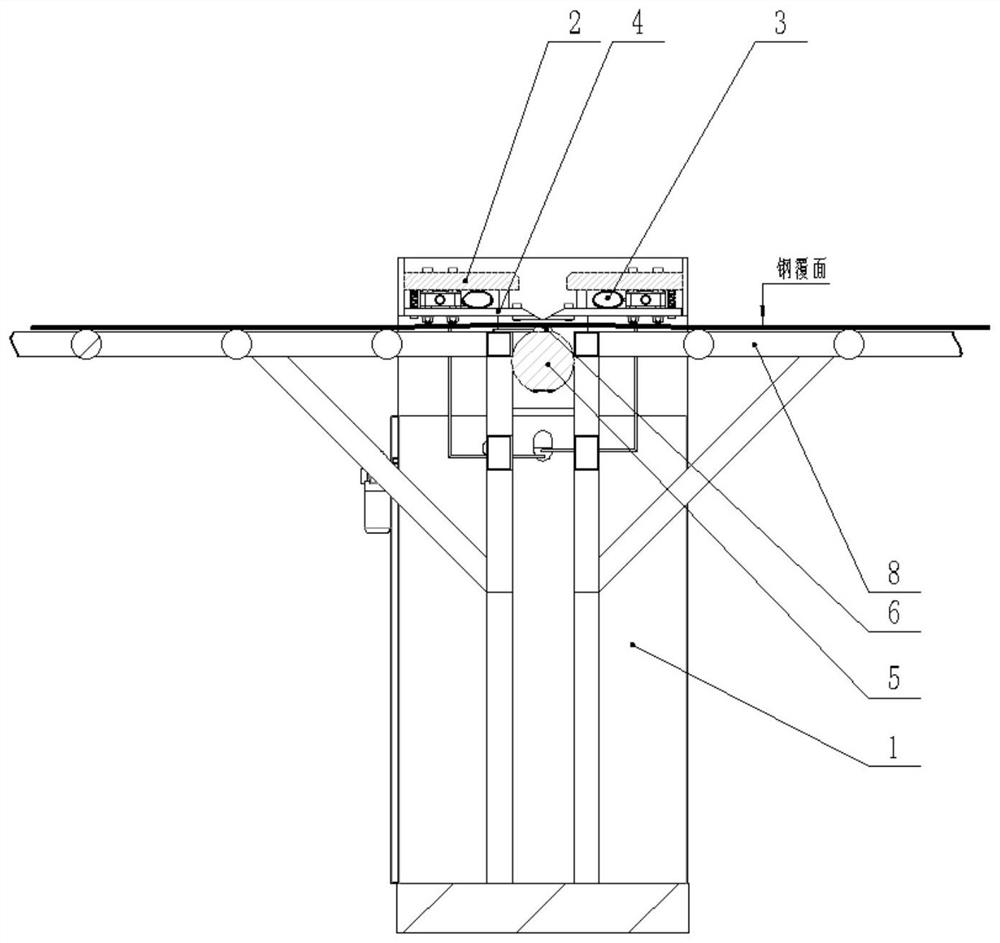

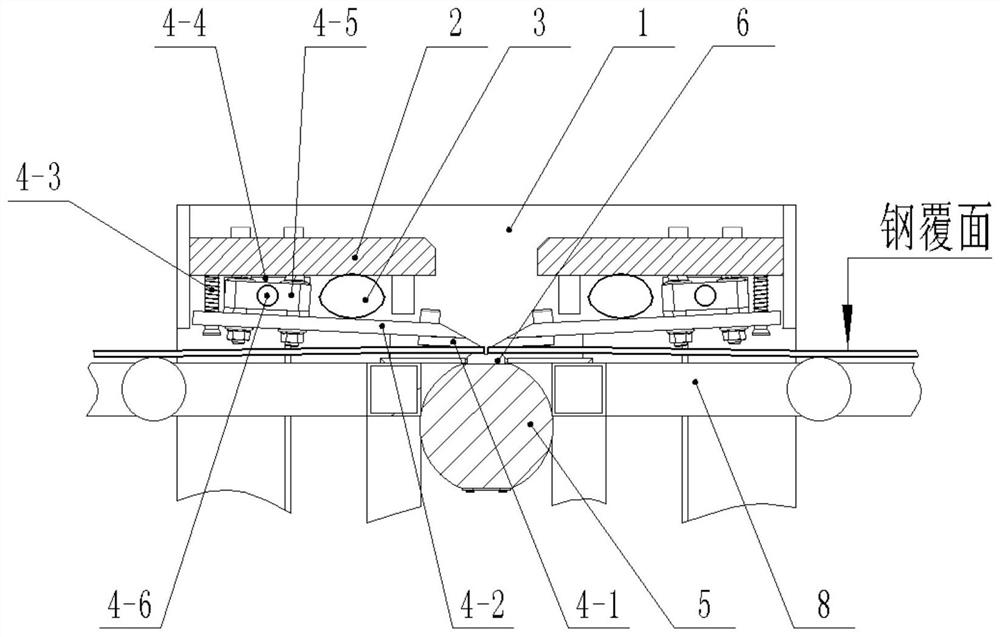

[0021] combine figure 1 , figure 2 As shown, a steel cladding and air duct automatic welding welding tool includes a bracket 1, an operating platform 2, an air bag 3, a clamping device 4, a round pipe bracket 5, a back protection plate 6, a locking frame 7, and a conveying frame 8. The bracket 1 is a tooling support system, which is a frame structure as a whole, with an electrical equipment cabinet on the side and a support on the bottom; an operating platform 2 is arranged on the top of the bracket 1, which is a flat structure and is used for equipment use. The working platform of the working platform; the clamping device 4 is arranged under the operating platform 2, and the clamping device 4 can rotate up and down and reset automatically; It can be propped up by the internal gas pressure, and the clamping device 4 can be driven to rotate downward during the propping up process to compress the weldment. The round pipe support 5 is connected below the operating platform 2 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com