Steel back barb equipment and method

A steel back and equipment technology, applied in the field of steel back barb equipment, can solve the problems of easy damage, low work efficiency, low production efficiency, etc., and achieve the effect of increasing connection strength, reducing processing difficulty and ensuring connection strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

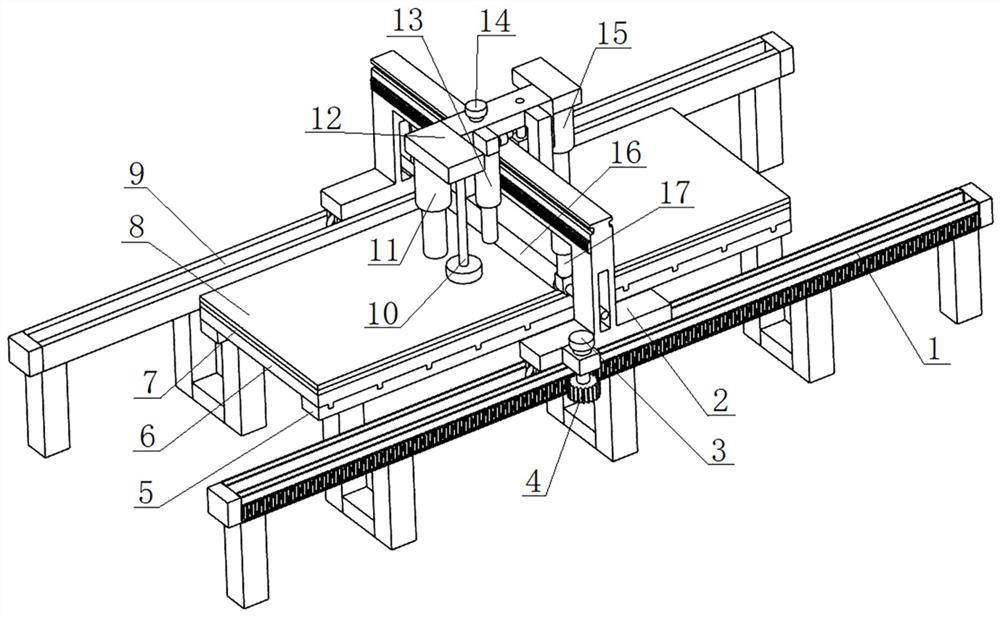

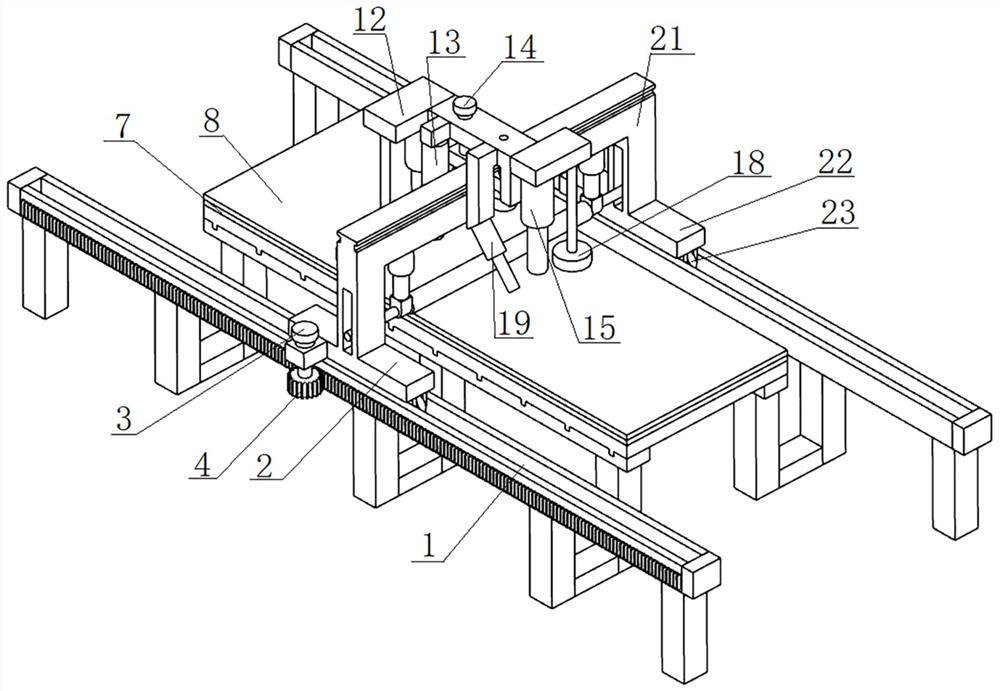

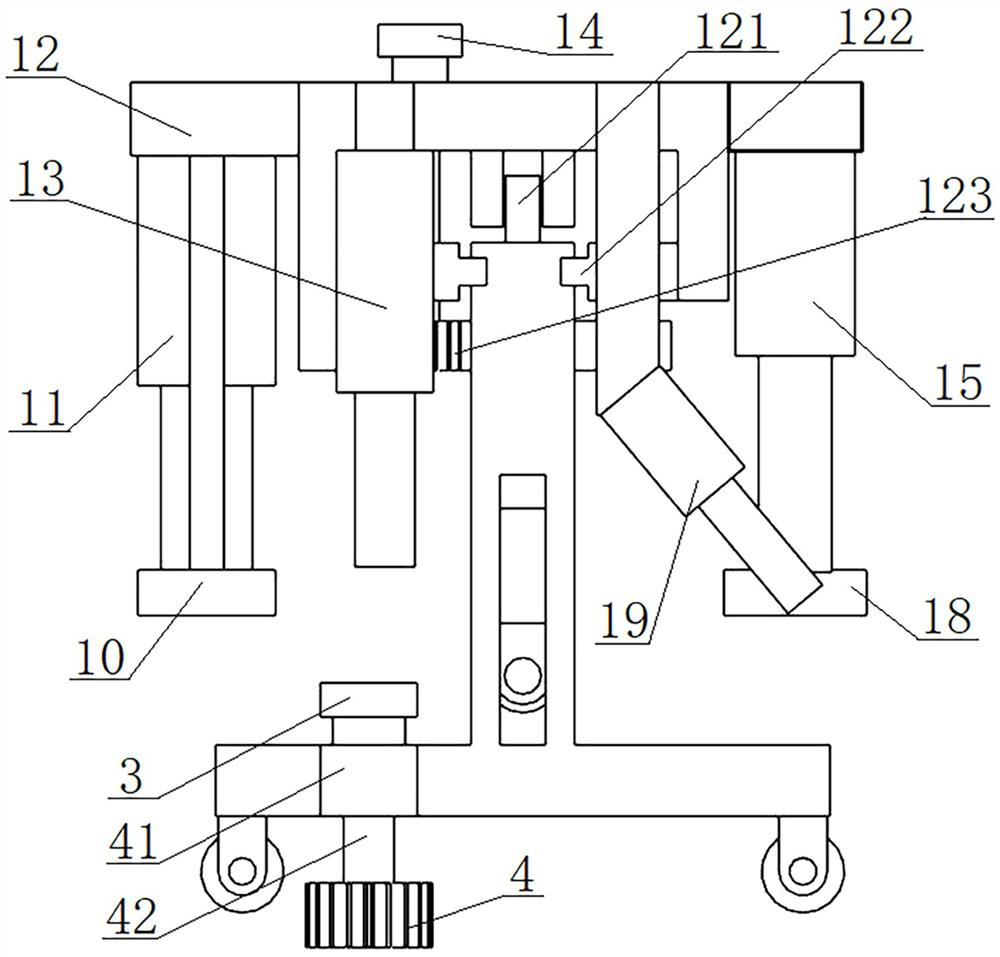

[0038] In order to illustrate the technical features of the solution more clearly, the solution will be described below through specific implementation modes.

[0039] see figure 1 , figure 2 , image 3 and Figure 6 , a steel back barb equipment, comprising a support frame 5, a first longitudinal rail 1 and a second longitudinal rail 9 respectively arranged on both sides of the support frame 5 and parallel to each other, slidably arranged on the first longitudinal rail 1 and the second longitudinal rail 9 The vertical moving frame 2 on the two vertical rails 9, the horizontal moving frame 12 slidably arranged on the vertical moving frame 2, the horizontal moving frame 12 is integrated with a numerical control cutting machine 11, a vacuum cylinder 13, a glue dispenser 19 and a point welding machine 15;

[0040] A power mechanism 1 is arranged on the longitudinal moving frame 2, and a power mechanism 2 is arranged on the transverse moving frame 12;

[0041] A support plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com