Large-specification resin ultrathin cutting blade and preparation method thereof

A cutting disc, large-size technology, applied in the field of large-scale resin ultra-thin cutting discs and its preparation, can solve the problems that restrict the use and development of large-diameter resin ultra-thin cutting discs, products are warped and scrapped, and maintain normal Work performance, reduce warping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

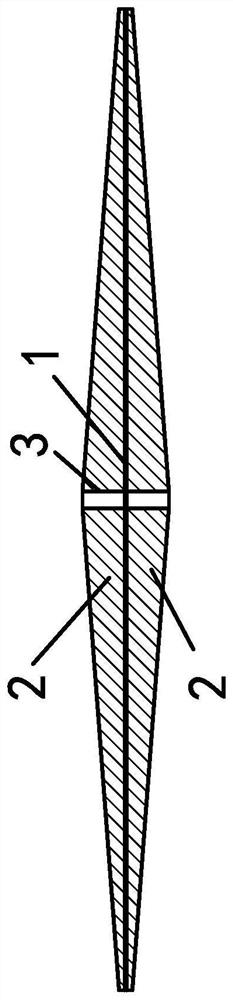

Image

Examples

Embodiment 1

[0027] S1. Weigh and mix the cutting layer raw materials according to the following mass percentages, and set aside;

[0028] 11% cryolite, 6% phenolic resin solution, 13% phenolic resin powder, 20% brown corundum plating, 30% white corundum plating, and 20% white corundum plating.

[0029] S2. Put the mixed cutting layer raw materials into the mold, flatten the bottom cutting layer with brackets; the mold is divided into two sides, one side is concave at the center of the circle, and the other side is horizontal; the angle between the inner concave surface and the horizontal plane is 0.5°.

[0030] S3. Put a layer of untwisted binding reinforced mesh on the cutting layer, bake the soft mesh with a heating device, and then press the mesh;

[0031] S4, put the cutting layer raw material into the mesh of S3, flatten the top layer of cutting layer with a bracket, put it into the grommet and press it to form,

[0032] S5, then carry out hardening treatment: first keep warm at 50°...

Embodiment 2

[0035] S1. Weigh and mix the cutting layer raw materials according to the following mass percentages, and set aside;

[0036] 11% cryolite, 6% phenolic resin solution, 13% phenolic resin powder, 20% brown corundum plating, 30% white corundum plating, and 20% white corundum plating.

[0037] S2. Put the mixed cutting layer raw materials into the mold, flatten the bottom cutting layer with brackets; the mold is divided into two sides, one side is concave at the center of the circle, and the other side is horizontal; the angle between the inner concave surface and the horizontal plane is 0.25°.

[0038] S3. Put a layer of untwisted binding reinforced mesh on the cutting layer, bake the soft mesh with a heating device, and then press the mesh;

[0039] S4, put the cutting layer raw material into the mesh of S3, flatten the top layer of cutting layer with a bracket, put it into the grommet and press it to form,

[0040] S5, then carry out hardening treatment: first keep warm at 45...

Embodiment 3

[0043] S1. Weigh and mix the cutting layer raw materials according to the following mass percentages, and set aside;

[0044] 11% cryolite, 6% phenolic resin solution, 13% phenolic resin powder, 20% brown corundum plating, 30% white corundum plating, and 20% white corundum plating.

[0045] S2. Put the mixed cutting layer raw materials into the mold, flatten the bottom cutting layer with brackets; the mold is divided into two sides, one side is concave at the center of the circle, and the other side is horizontal; the angle between the inner concave surface and the horizontal plane is 0.75°.

[0046] S3. Put a layer of untwisted binding reinforced mesh on the cutting layer, bake the soft mesh with a heating device, and then press the mesh;

[0047] S4, put the cutting layer raw material into the mesh of S3, flatten the top layer of cutting layer with a bracket, put it into the grommet and press it to form,

[0048] S5, then carry out hardening treatment: first keep warm at 55...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Edge thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com