Water-based ink as well as preparation method and application thereof

A water-based ink and nano-filler technology, applied in the direction of ink, application, household appliances, etc., can solve the problems of peeling, ink fading, yellowing, etc., and achieve the effect of improving high temperature resistance and weather resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

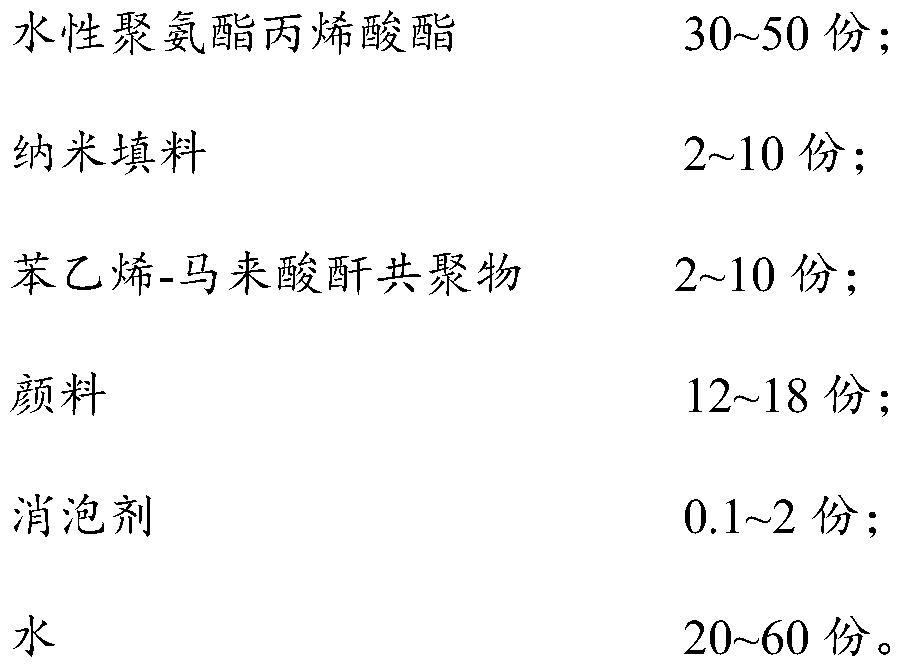

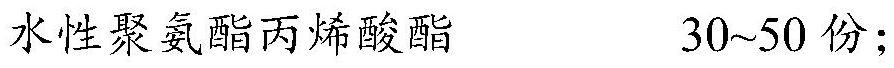

[0032] Embodiment 1 provides a kind of water-based ink, and component content is shown in Table 1, and preparation method is as follows:

[0033] Stir and mix water-based polyurethane acrylate, nano filler, styrene-maleic anhydride copolymer, pigment, defoamer and water at a stirring speed of 1300 rpm for 50 minutes to obtain a water-based ink.

Embodiment 2~5

[0035] Embodiments 2-5 provide a series of water-based inks, the component contents are shown in Table 1, and the preparation method is the same as that of Embodiment 1.

[0036] The component content (part) of table 1 embodiment 1~5

[0037]

[0038]

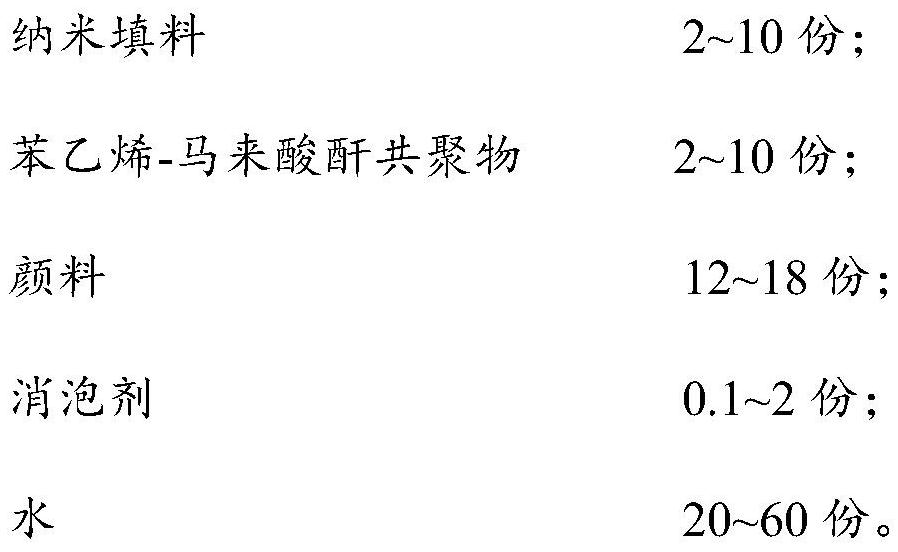

Embodiment 6~7 and comparative example 1~3

[0040] Examples 6-7 and Comparative Examples 1-3 provide a series of water-based inks, the component contents are shown in Table 2, and the preparation method is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com