Thermal battery-electrolytic tank coupling hydrogen production system

A technology of hydrogen production system and electrolytic cell, which is applied in the direction of electrolysis process, electrolysis components, cells, etc., can solve the problems of system efficiency reduction, achieve optimal matching, realize the effect of hydrogen evolution and oxygen evolution kinetics enhancement, and effective utilization reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Specific technical solutions of the present invention will be described in connection with examples.

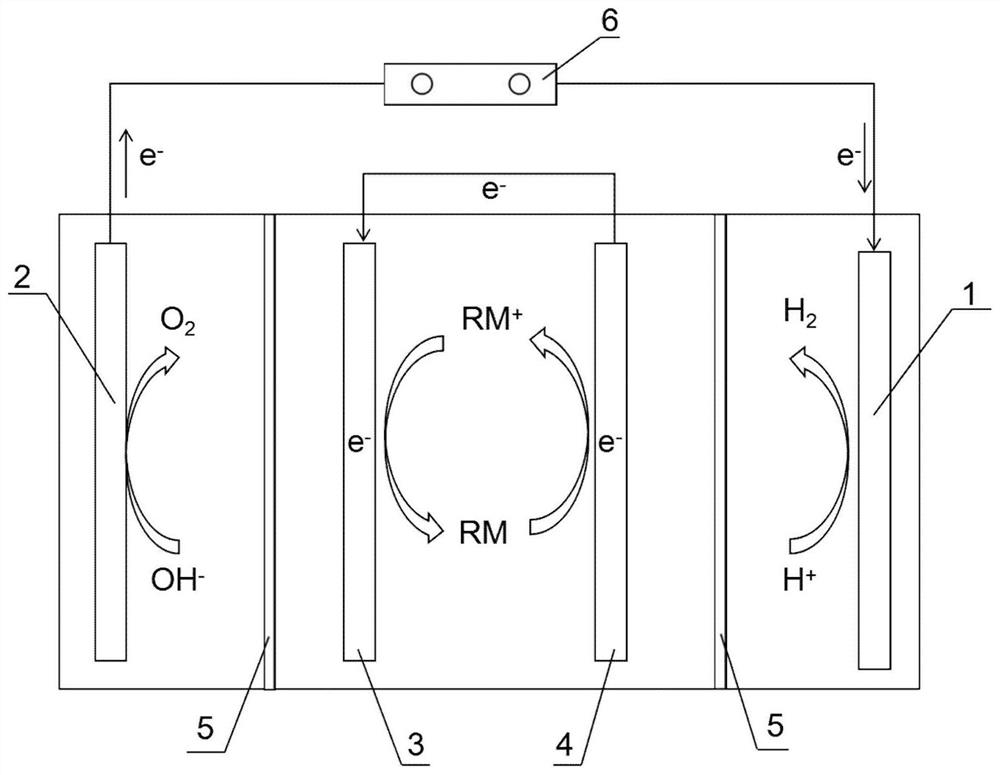

[0018] Such as figure 1 As shown, a thermal cell-electrolytic pool coupled hydrogen hydrogen system, including the electrolytic cell, an electrolyte in the electrolytic tank, and sequentially disposed in the electrolytic cell 2, a heat chemical battery anode 3, a thermochemical cathode 4, an oxygen Anode 1;

[0019] The chip cathode 2 and the thermochemical battery anode 3 are separated by separation of the exchange membrane 5 between the heat chemical cell cathode 4 and the epoxy anode 1, and the exchange membrane 5 is a cation exchange membrane or a proton exchange membrane;

[0020] The thermochemical battery anode 3, and the heat chemical cell cathode 4 can be separated by a porous polytetrafluoroide, an ion exchange membrane or the like.

[0021] When the hydrogenation and an oxygen independent operation, the hydrogen pole 2 and the thermochemicals anode 3, the oxygen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com