Rapid construction method of high-gas or coal and gas outburst coal seam stope face crossheading

A technology for mining face and gas outburst, applied in gas discharge, mining equipment, ground mining, etc., can solve the problems of large number of people, low driving speed, unbalanced mining, etc., to increase the scope of influence, increase the speed of extraction, and reduce the difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

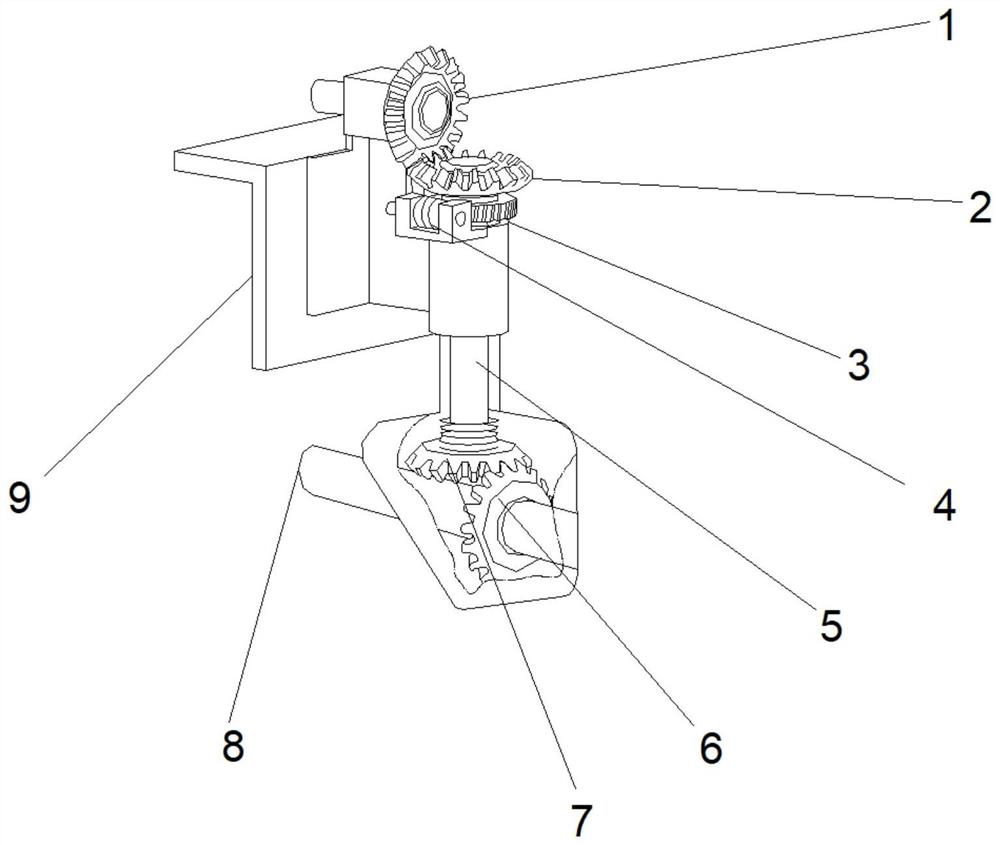

[0041] see Figure 1 to Figure 6 , which is a rapid construction method for a high-gas or coal and gas outburst coal seam recovery working face along the channel. In this embodiment, a rapid construction method for a high gas or coal and gas outburst coal seam recovery working face along the channel. The cross-sectional size is 3m Taking a high gas or coal and gas outburst coal seam with ×4m along the channel as an example, the following steps are included:

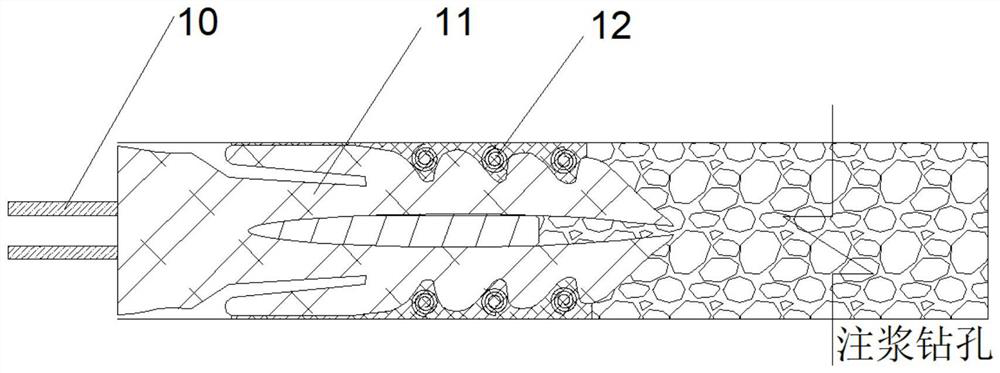

[0042] S1: Use the universal drill rod adjustment device to cooperate with the drilling rig to construct the grouting drilling 17 along the coal roadway section. After the grouting drilling 17 is constructed, immediately put the hole sealer into the grouting drilling 17 under construction ; Then the grouting pipe 10 is screwed into the hole sealer. The hole sealer body 11 is made of engineering plastics, and the whole is a hollow structure with good elasticity. The inside is provided with connecting threads, and the outer...

Embodiment 2

[0054] In this embodiment, a high gas or coal and gas outburst coal seam with a cross-sectional size of 3m×5m is taken as an example, and the rest are consistent with that of Embodiment 1.

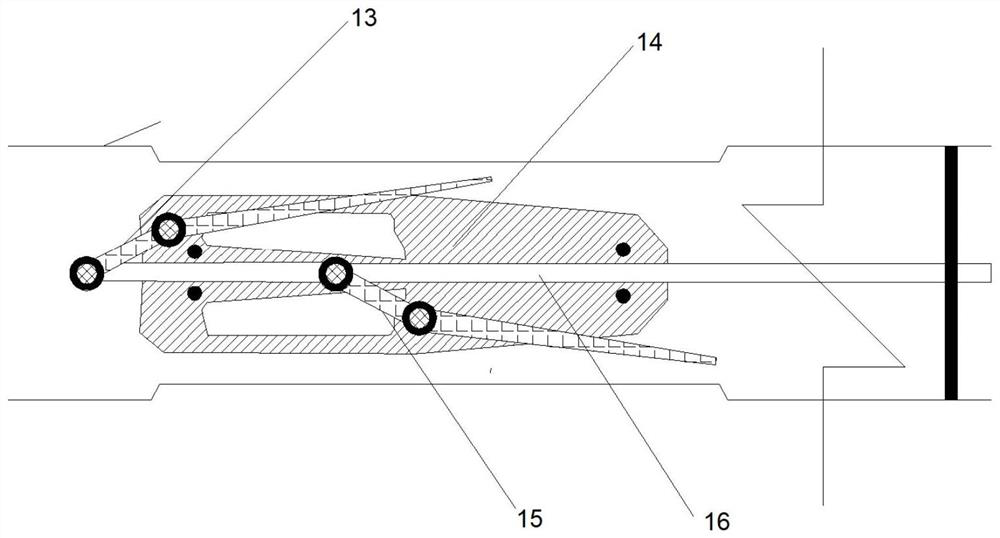

[0055] The present invention provides a rapid construction method for a high-gas or coal-and-gas outburst coal seam recovery working face along the trough, by uniformly constructing several injectors on both sides of the outer contour line of the coal body along the mining working face along the trough on the coal roadway section. After the grout is solidified, the coal body that is to be extended along the trough of the mining face is completely isolated from the two sides, so as to prevent the gas of the two sides of the coal seam from flowing into the mining face along the trough. Extending the flow of the coal body greatly reduces the difficulty of gas drainage in the coal roadway excavation face. Construction and reconstruction of gas drainage boreholes, and the formation of coal cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com