Single pumping tilt cylinder valve

A pumping and single-connection technology, applied in the direction of multi-way valves, valve devices, valve details, etc., can solve the problems of high production cost, inconvenient installation and distribution, complex structure, etc., and achieve simple internal structure, compact and light volume, and work The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

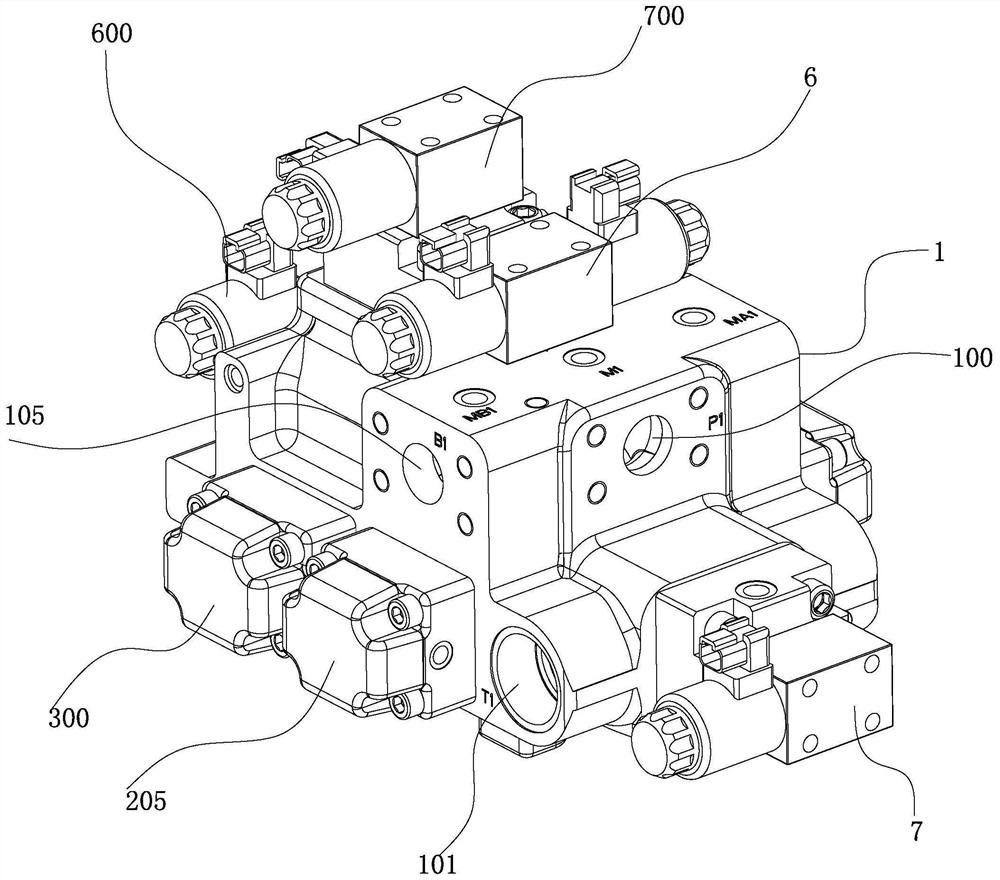

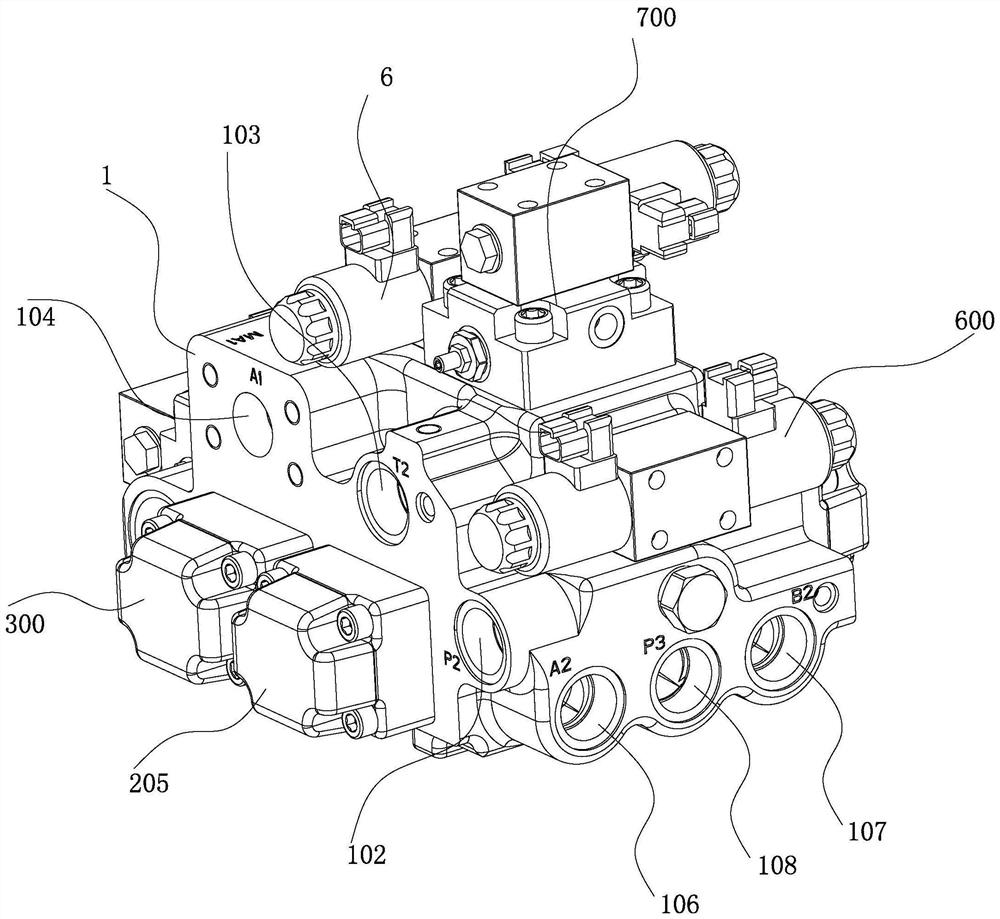

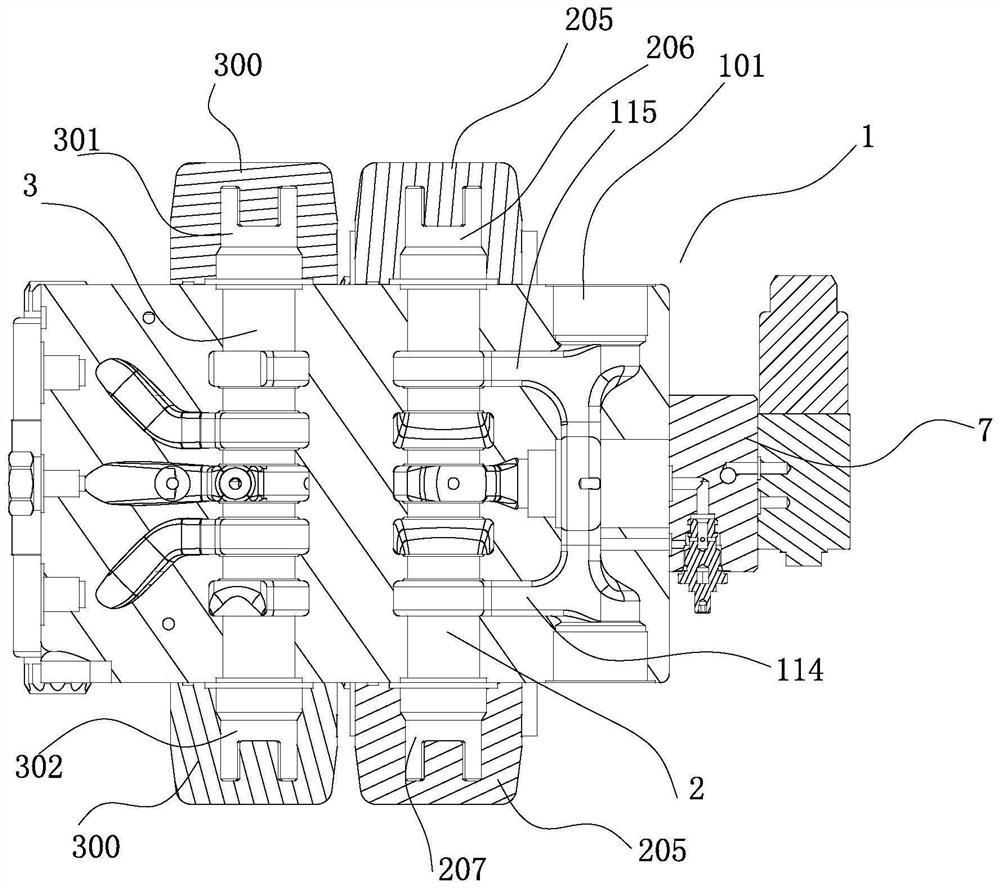

[0034] see Figure 1 to Figure 7 shown;

[0035] This embodiment discloses a single-connected pumping swing cylinder valve, which is connected to machinery such as a pump truck, and is used to control the alternating operation of the pumping cylinder group, the alternating operation of the swinging cylinder group, and the combined alternate operation of the pumping cylinder group and the swinging cylinder group. , in this embodiment, the valve body 1 is provided with the first oil inlet 100, the second oil inlet 102 and the third oil inlet 108 respectively connected with the external oil source; and the valve body 1 is provided with the pumping The first oil outlet 104 and the second oil outlet 105 connected to the rodless chamber oil port of the oil cylinder group and the third oil outlet 106 and the fourth oil outlet 107 communicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com